South Korea 3D Printing Market Size, Share, Trends and Forecast by Technology, Process, Material, Offering, Application, End User, and Region, 2025-2033

South Korea 3D Printing Market Overview:

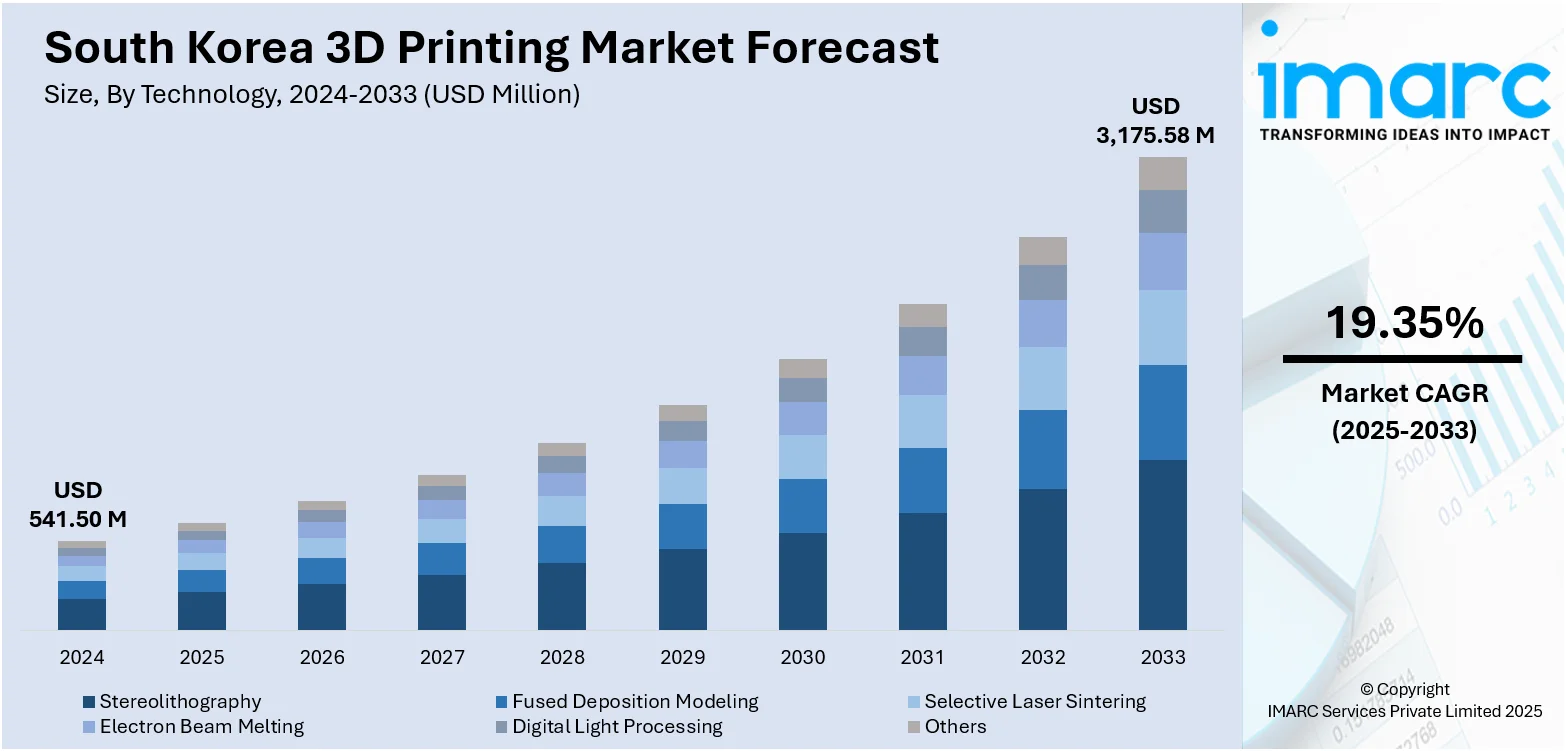

The South Korea 3D printing market size reached USD 541.50 Million in 2024. Looking forward, the market is projected to reach USD 3,175.58 Million by 2033, exhibiting a growth rate (CAGR) of 19.35% during 2025-2033. The market is driven by strong government funding and forward‑looking strategic planning. Also, medical sector customization requirements creating high‑value use cases are providing an impetus to the market. In addition to this, integration of AI‑enabled automation aligned with national Industry 4.0 frameworks is further augmenting the South Korea 3D printing market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024

|

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 541.50 Million |

| Market Forecast in 2033 | USD 3,175.58 Million |

| Market Growth Rate 2025-2033 | 19.35% |

South Korea 3D Printing Market Trends:

Government Investments and Strategic Industry Roadmap

The South Korean government has initiated substantial investments to catalyze additive manufacturing adoption across industry sectors. Ministries have allocated millions in R&D funding and established educational centers in universities and vocational institutions. On June 25, 2025, South Korea’s KITECH and partners validated a 130-liter 3D printed titanium tank for space use, successfully withstanding 330 bar pressure at -196 °C, which is 50% above its operating limit of 220 bar. Built using laser-wire directed energy deposition, the tank met aerospace standards and showed no structural defects. The project supports South Korea’s push for domestic space hardware and advanced metal additive manufacturing. Conferences and standardization workshops support alignment with ISO and ASTM norms, promoting interoperability and technological competitiveness. Public agencies are subsidizing pilot projects across healthcare, aerospace, automotive, and smart construction sectors to demonstrate 3D printing use cases. As industrial parks dedicated to additive technologies emerge, particularly around smart factory zones, governmental support also extends to SMEs seeking to upgrade manufacturing capabilities. Institutional infrastructure and coordinated strategic planning are a central force driving the South Korea 3D printing market growth.

To get more information on this market, Request Sample

AI Integration, Automation Trends and Industry 4.0 Alignment

South Korean industry is integrating AI, robotics, and digital automation into its manufacturing transformation roadmap. AI-enhanced additive manufacturing platforms now support autonomous workflow orchestration, defect prediction and material optimization. Also, innovations in new materials are creating a favorable market outlook. Researchers at the Korea Electrotechnology Research Institute developed a new high-resolution 3D printing method in 2025 using MXene, achieving a resolution of 1.3 micrometers, 270 times finer than existing techniques. The process eliminates the need for binding agents by leveraging the meniscus effect and MXene’s hydrophilic properties, allowing precise, electrically conductive microstructures without post-processing. Moreover, integration with Industry 4.0 initiatives reduces reliance on manual post‑processing and ensures consistency across large print batches. Automotive, aerospace, and electronics firms leverage connected factory designs and digital twins to optimize multi-technology workflows. Standardization efforts and robotics alignment within smart factories strengthen the ecosystem of design, simulation and printing tools. Real-time analytics and edge computing integration enable dynamic calibration of print parameters during operation. This synergy of AI, automation and standardized platforms ensures that 3D printing scales across industries while maintaining high quality and throughput efficiency.

South Korea 3D Printing Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional levels for 2025-2033. Our report has categorized the market based on technology, process, material, offering, application, and end user.

Technology Insights:

- Stereolithography

- Fused Deposition Modeling

- Selective Laser Sintering

- Electron Beam Melting

- Digital Light Processing

- Others

The report has provided a detailed breakup and analysis of the market based on the technology. This includes stereolithography, fused deposition modeling, selective laser sintering, electron beam melting, digital light processing, and others.

Process Insights:

- Binder Jetting

- Directed Energy Deposition

- Material Extrusion

- Material Jetting

- Power Bed Fusion

- Sheet Lamination

- Vat Photopolymerization

The report has provided a detailed breakup and analysis of the market based on the process. This includes binder jetting, directed energy deposition, material extrusion, material jetting, power bed fusion, sheet lamination, and vat photopolymerization.

Material Insights:

- Photopolymers

- Plastics

- Metals and Ceramics

- Others

The report has provided a detailed breakup and analysis of the market based on the material. This includes photopolymers, plastics, metals and ceramics, and others.

Offering Insights:

- Printer

- Material

- Software

- Service

The report has provided a detailed breakup and analysis of the market based on the offering. This includes printer, material, software, and service.

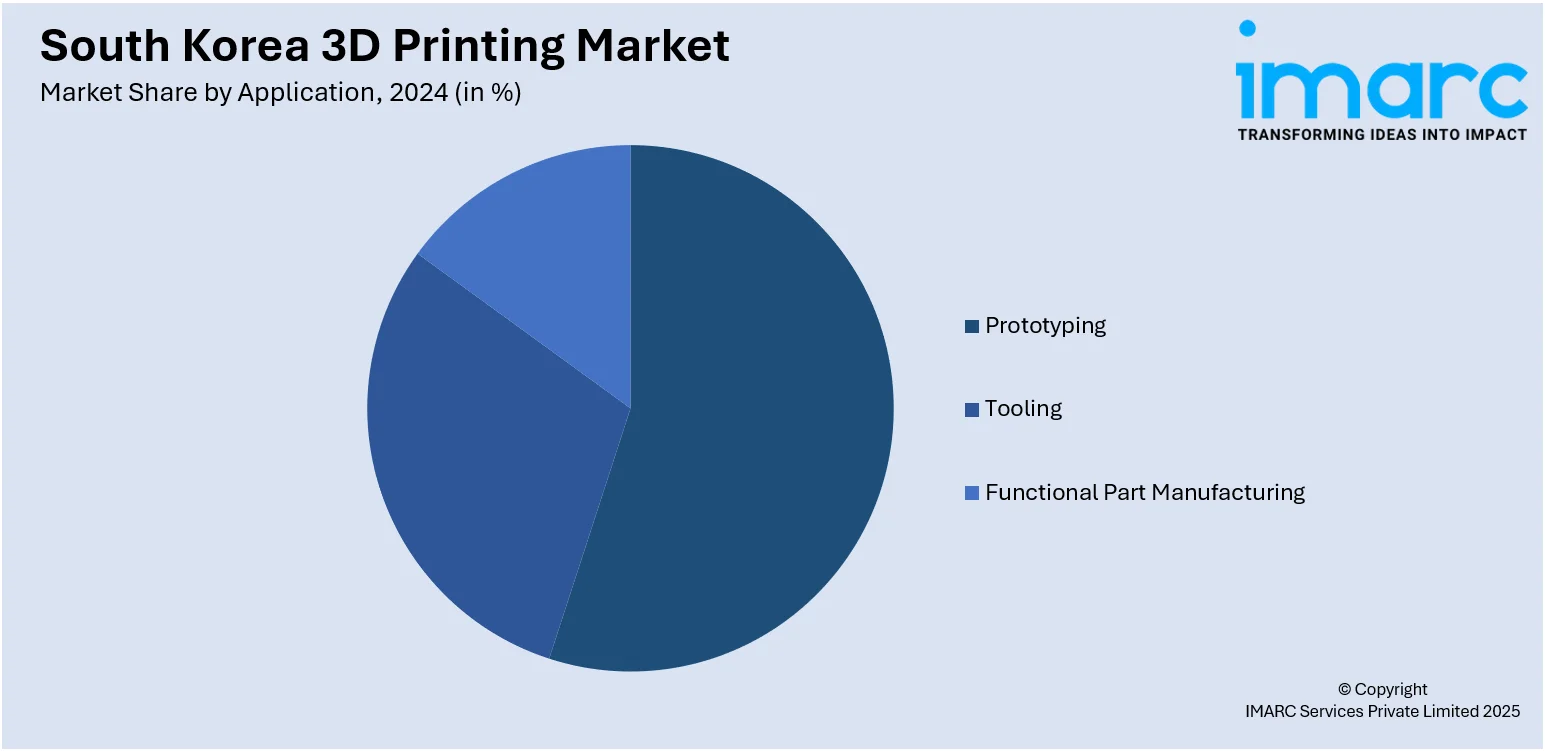

Application Insights:

- Prototyping

- Tooling

- Functional Part Manufacturing

The report has provided a detailed breakup and analysis of the market based on the application. This includes prototyping, tooling, and functional part manufacturing.

End User Insights:

- Consumer Products

- Machinery

- Healthcare

- Aerospace

- Automobile

- Others

The report has provided a detailed breakup and analysis of the market based on the end user. This includes consumer products, machinery, healthcare, aerospace, automobile, and others.

Regional Insights:

- Seoul Capital Area

- Yeongnam (Southeastern Region)

- Honam (Southwestern Region)

- Hoseo (Central Region)

- Others

The report has also provided a comprehensive analysis of all major regional markets. This includes Seoul Capital Area, Yeongnam (Southeastern Region), Honam (Southwestern Region), Hoseo (Central Region), and others.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

South Korea 3D Printing Market News:

- On June 19, 2025, South Korean satellite launch firm INNOSPACE launched its Advanced Manufacturing Division to produce in-house rocket engines and components using metal 3D printing. The division passed ISO/ASTM 52941-20 shipment inspection, becoming the first in South Korea to meet international standards for aerospace AM equipment. The new facility has begun full-scale operations, completing 13 key components and targeting up to 50 percent cost reduction through integrated additive manufacturing.

- On April 15, 2025, South Korea’s Marine Corps Logistics Group deployed the country’s first mobile, robot-based metal 3D printer using Meltio’s wire-laser Directed Energy Deposition (DED) technology, enabling on-demand production of spare parts for military vehicles. Developed with AM Solutions, the containerized system allows field-based manufacturing and supports key platforms like the KAAV, reducing repair costs and downtime. This move aligns with plans to expand 3D printing capacity across the defense sector over the next two years and highlights South Korea’s growing investments in advanced additive manufacturing.

South Korea 3D Printing Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Technologies Covered | Stereolithography, Fused Deposition Modeling, Selective Laser Sintering, Electron Beam Melting, Digital Light Processing, Others |

| Processes Covered | Binder Jetting, Directed Energy Deposition, Material Extrusion, Material Jetting, Power Bed Fusion, Sheet Lamination, Vat Photopolymerization |

| Materials Covered | Photopolymers, Plastics, Metals and Ceramics, Others |

| Offerings Covered | Printer, Material, Software, Service |

| Applications Covered | Prototyping, Tooling, Functional Part Manufacturing |

| End Users Covered | Consumer Products, Machinery, Healthcare, Aerospace, Automobile, Others |

| Regions Covered | Seoul Capital Area, Yeongnam (Southeastern Region), Honam (Southwestern Region), Hoseo (Central Region), Others |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the South Korea 3D printing market performed so far and how will it perform in the coming years?

- What is the breakup of the South Korea 3D printing market on the basis of technology?

- What is the breakup of the South Korea 3D printing market on the basis of process?

- What is the breakup of the South Korea 3D printing market on the basis of material?

- What is the breakup of the South Korea 3D printing market on the basis of offering?

- What is the breakup of the South Korea 3D printing market on the basis of application?

- What is the breakup of the South Korea 3D printing market on the basis of end user?

- What is the breakup of the South Korea 3D printing market on the basis of region?

- What are the various stages in the value chain of the South Korea 3D printing market?

- What are the key driving factors and challenges in the South Korea 3D printing market?

- What is the structure of the South Korea 3D printing market and who are the key players?

- What is the degree of competition in the South Korea 3D printing market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the South Korea 3D printing market from 2019-2033.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the South Korea 3D printing market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the South Korea 3D printing industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)