Tetraethyl Orthosilicate (TEOS) Production Cost Analysis Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue

Report Overview:

IMARC Group’s report, titled “Tetraethyl Orthosilicate (TEOS) Production Cost Analysis Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue,” provides a complete roadmap for setting up a tetraethyl orthosilicate (TEOS) production plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc. The tetraethyl orthosilicate (TEOS) project report provides detailed insights into project economics, including capital investments, project funding, operating expenses, income and expenditure projections, fixed costs vs. variable costs, direct and indirect costs, expected ROI and net present value (NPV), profit and loss account, financial analysis, etc.

Tetraethyl Orthosilicate (TEOS) Market Analysis:

The market is primarily driven by the increasing demand for high-purity silica in the semiconductor industry. TEOS serves as a critical precursor in chemical vapor deposition (CVD) processes for producing thin films used in microelectronics and integrated circuits. Moreover, the growing construction sector is accelerating the use of TEOS in advanced coatings, sealants, and high-performance concrete applications, particularly in infrastructure development projects requiring enhanced durability and resistance. There is a steady growth in the construction sector. According to the U.S. Census Bureau, the total value of construction spending in 2024 reached USD 2,154.4 Billion, recording a 6.5 percent increase from 2023. This upward trend is driving demand for TEOS-based materials as infrastructure and commercial projects increasingly incorporate high-performance coatings and concrete additives to enhance structural longevity and environmental resistance.

In addition to this, the rising adoption of TEOS in the production of sol-gel-derived materials is strengthening market growth, as these materials are widely applied in optics, sensors, and nanotechnology-based innovations. The expanding automotive sector is also contributing to tetraethyl orthosilicate (TEOS) market growth. According to an industry report, the United States exported over 160,000 medium and heavy trucks, 1.6 million light cars, and USD 93.7 Billion worth of auto parts in 2023, reflecting the strength of the automotive sector. This expansion is significantly increasing the demand for advanced materials that enhance vehicle performance and longevity. As a result, the use of TEOS-based coatings and adhesives is rising, as they provide superior durability, corrosion resistance, and structural reinforcement.

Tetraethyl Orthosilicate (TEOS) Market Trends:

Advancements in High-Purity TEOS for Semiconductor Applications

The increasing demand for ultra-high-purity TEOS in semiconductor fabrication is driving innovation in purification techniques and production processes. There is a strong growth in global semiconductor sales, which reached USD 627.6 Billion in 2024, reflecting a 19.1% increase from USD 526.8 Billion in 2023. As semiconductor manufacturers expand production to meet rising demand, the need for TEOS with minimal impurities becomes even more critical to ensure the reliability of chemical vapor deposition (CVD) and atomic layer deposition (ALD) processes used in integrated circuit manufacturing. Moreover, the rising complexity of semiconductor devices, including the development of 3D NAND flash memory and advanced logic chips, is necessitating more stringent material quality standards. The shift towards smaller process nodes in semiconductor fabrication is also reinforcing the need for high-performance precursor materials like TEOS, which is increasing tetraethyl orthosilicate (TEOS) market demand. Additionally, increasing investments in semiconductor manufacturing hubs, particularly in Asia-Pacific, are driving regional TEOS production, reducing dependency on imports and improving supply chain resilience.

Adoption of TEOS in Silica Aerogels for Thermal Insulation

The rising focus on energy efficiency and lightweight materials is increasing the adoption of TEOS in silica aerogel production, thereby positively influencing tetraethyl orthosilicate (TEOS) market outlook. Silica aerogels, known for their exceptional thermal insulation and low density, are being used in construction, aerospace, and industrial applications to enhance energy conservation. TEOS serves as a key precursor in the sol-gel synthesis of aerogels, enabling the formation of highly porous and lightweight structures with superior insulating properties. A research article published in March 2024 examines the development of aminated silica aerogel monoliths using a cost-effective, self-catalyzed polycondensation method with 3-aminopropyl triethoxysilane (APTES) and tetraethyl orthosilicate (TEOS). The optimized TA-NH2-2.5 aerogel demonstrated high CO2 capture capacity (3.10 mmol/g), strong CO2/N2 selectivity (9 5 1), and efficient removal of heavy metal ions such as Pb²⁺, Hg²⁺, Ni²⁺, and Cu²⁺, alongside impressive mechanical strength (13.96 MPa) and low thermal conductivity (29.1 mW/mK). These findings highlight the potential of aminated aerogels as robust, multifunctional materials for industrial CO2 capture and environmental remediation.

Latest Industry News:

The market is also being driven by increasing investments and capacity expansions:

- August 28, 2024: EcoPower Chemical has introduced Crosile® Si28, a high-purity tetraethyl orthosilicate (TEOS) with a purity exceeding 99.0%. This versatile chemical serves as a crosslinking agent in silicone sealants, a binder in precision casting, and a source for producing high-purity silica. Additionally, TEOS is utilized in the semiconductor industry for silicon dioxide film formation and in the production of several silane coupling agents as a basic material.

- February 13, 2025: Sensorix GmbH has expanded its product line by introducing electrochemical gas sensors designed to detect phosphine (PH₃), arsine (AsH₃), phosgene (COCl₂), fluorine (F₂), hydrogen (H₂), and tetraethyl orthosilicate (TEOS). These sensors, including models such as TEOS 100 and COCl₂ 1, are engineered for industrial safety applications, providing exceptional stability and rapid, reliable performance. Sensorix offers these sensors in standard formats like 4S, 7S, Mini, Classic, and Smart, as well as customized configurations to meet specific client requirements.

The following aspects have been covered in the tetraethyl orthosilicate (TEOS) production plant report:

-production-cost-analysis-report-image.webp)

To gain detailed insights into the report, Request Sample

- Market Analysis:

- Market Trends

- Market Breakup by Segment

- Market Breakup by Region

- Price Analysis

- Impact of COVID-19

- Market Forecast

The report provides insights into the landscape of the tetraethyl orthosilicate (TEOS) industry at the global level. The report also provides a segment-wise and region-wise breakup of the global tetraethyl orthosilicate (TEOS) industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of tetraethyl orthosilicate (TEOS), along with the industry profit margins.

- Detailed Process Flow:

- Product Overview

- Unit Operations Involved

- Mass Balance and Raw Material Requirements

- Quality Assurance Criteria

- Technical Tests

The report also provides detailed information related to the tetraethyl orthosilicate (TEOS) manufacturing process flow and various unit operations involved in a production plant. Furthermore, information related to mass balance and raw material requirements has also been provided in the report with a list of necessary quality assurance criteria and technical tests.

- Project Details, Requirements and Costs Involved:

- Land, Location and Site Development

- Plant Layout

- Machinery Requirements and Costs

- Raw Material Requirements and Costs

- Packaging Requirements and Costs

- Transportation Requirements and Costs

- Utility Requirements and Costs

- Human Resource Requirements and Costs

The report provides a detailed location analysis covering insights into the land location, selection criteria, location significance, environmental impact, expenditure, and other tetraethyl orthosilicate (TEOS) production plant costs. Additionally, the report provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

- Project Economics:

- Capital Investments

- Operating Costs

- Expenditure Projections

- Revenue Projections

- Taxation and Depreciation

- Profit Projections

- Financial Analysis

The report also covers a detailed analysis of the project economics for setting up a tetraethyl orthosilicate (TEOS) production plant. This includes the analysis and detailed understanding of tetraethyl orthosilicate (TEOS) production plant costs, including capital expenditure (CapEx), operating expenditure (OpEx), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis. Furthermore, the report also provides a detailed analysis of the regulatory procedures and approvals, information related to financial assistance, along with a comprehensive list of certifications required for setting up a tetraethyl orthosilicate (TEOS) production plant.

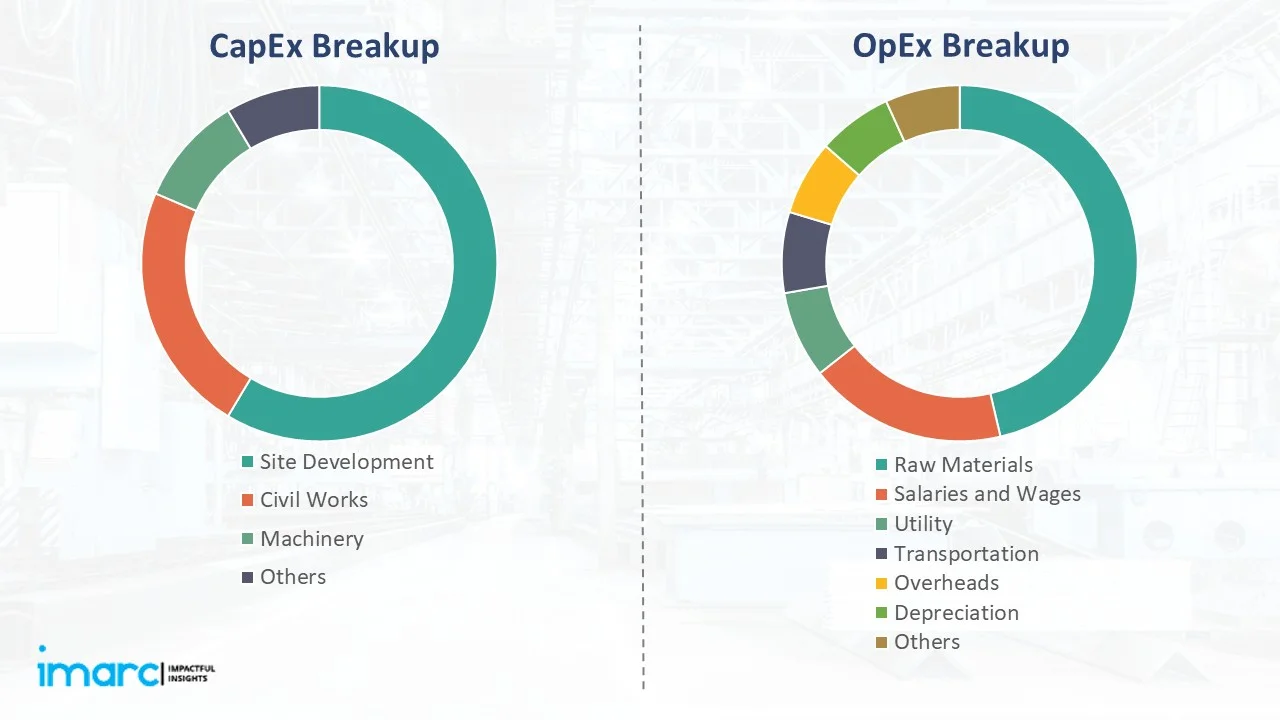

Capital Expenditure Breakdown:

| Particulars | Cost (in US$) |

|---|---|

| Land and Site Development Costs | XX |

| Civil Works Costs | XX |

| Machinery Costs | XX |

| Other Capital Costs | XX |

Operational Expenditure Breakdown:

| Particulars | In % |

|---|---|

| Raw Material Cost | XX |

| Utility Cost | XX |

| Transportation Cost | XX |

| Packaging Cost | XX |

| Salaries and Wages | XX |

| Depreciation | XX |

| Other Expenses | XX |

Profitability Analysis:

| Particulars | Unit | Year 1 | Year 2 | Year 3 | Year 4 | Year 5 |

|---|---|---|---|---|---|---|

| Total Income | US$ | XX | XX | XX | XX | XX |

| Total Expenditure | US$ | XX | XX | XX | XX | XX |

| Gross Profit | US$ | XX | XX | XX | XX | XX |

| Gross Margin | % | XX | XX | XX | XX | XX |

| Net Profit | US$ | XX | XX | XX | XX | XX |

| Net Margin | % | XX | XX | XX | XX | XX |

Report Coverage:

| Report Features | Details |

|---|---|

| Product Name | Tetraethyl Orthosilicate (TEOS) |

| Report Coverage | Detailed Process Flow: Unit Operations Involved, Quality Assurance Criteria, Technical Tests, Mass Balance, and Raw Material Requirements Land, Location and Site Development: Selection Criteria and Significance, Location Analysis, Project Planning and Phasing of Development, Environmental Impact, Land Requirement and Costs Plant Layout: Importance and Essentials, Layout, Factors Influencing Layout Plant Machinery: Machinery Requirements, Machinery Costs, Machinery Suppliers (Provided on Request) Raw Materials: Raw Material Requirements, Raw Material Details and Procurement, Raw Material Costs, Raw Material Suppliers (Provided on Request) Packaging: Packaging Requirements, Packaging Material Details and Procurement, Packaging Costs, Packaging Material Suppliers (Provided on Request) Other Requirements and Costs: Transportation Requirements and Costs, Utility Requirements and Costs, Energy Requirements and Costs, Water Requirements and Costs, Human Resource Requirements and Costs Project Economics: Capital Costs, Techno-Economic Parameters, Income Projections, Expenditure Projections, Product Pricing and Margins, Taxation, Depreciation Financial Analysis: Liquidity Analysis, Profitability Analysis, Payback Period, Net Present Value, Internal Rate of Return, Profit and Loss Account, Uncertainty Analysis, Sensitivity Analysis, Economic Analysis Other Analysis Covered in The Report: Market Trends and Analysis, Market Segmentation, Market Breakup by Region, Price Trends, Competitive Landscape, Regulatory Landscape, Strategic Recommendations, Case Study of a Successful Venture |

| Currency | US$ (Data can also be provided in the local currency) |

| Customization Scope | The report can also be customized based on the requirement of the customer |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through email (We can also provide the editable version of the report in PPT/Word format on special request) |

Report Customization

While we have aimed to create an all-encompassing tetraethyl orthosilicate (TEOS) production plant project report, we acknowledge that individual stakeholders may have unique demands. Thus, we offer customized report options that cater to your specific requirements. Our consultants are available to discuss your business requirements, and we can tailor the report's scope accordingly. Some of the common customizations that we are frequently requested to make by our clients include:

- The report can be customized based on the location (country/region) of your plant.

- The plant’s capacity can be customized based on your requirements.

- Plant machinery and costs can be customized based on your requirements.

- Any additions to the current scope can also be provided based on your requirements.

Why Buy IMARC Reports?

- The insights provided in our reports enable stakeholders to make informed business decisions by assessing the feasibility of a business venture.

- Our extensive network of consultants, raw material suppliers, machinery suppliers and subject matter experts spans over 100+ countries across North America, Europe, Asia Pacific, South America, Africa, and the Middle East.

- Our cost modeling team can assist you in understanding the most complex materials. With domain experts across numerous categories, we can assist you in determining how sensitive each component of the cost model is and how it can affect the final cost and prices.

- We keep a constant track of land costs, construction costs, utility costs, and labor costs across 100+ countries and update them regularly.

- Our client base consists of over 3000 organizations, including prominent corporations, governments, and institutions, who rely on us as their trusted business partners. Our clientele varies from small and start-up businesses to Fortune 500 companies.

- Our strong in-house team of engineers, statisticians, modeling experts, chartered accountants, architects, etc. has played a crucial role in constructing, expanding, and optimizing sustainable production plants worldwide.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Frequently Asked Questions

Capital requirements generally include land acquisition, construction, equipment procurement, installation, pre-operative expenses, and initial working capital. The total amount varies with capacity, technology, and location.

To start a tetraethyl orthosilicate (TEOS) production business, one needs to conduct a market feasibility study, secure required licenses, arrange funding, select suitable land, procure equipment, recruit skilled labor, and establish a supply chain and distribution network.

Tetraethyl orthosilicate (TEOS) production requires raw materials such as silicon tetrachloride, ethanol, and ethyl alcohol. Catalysts like acid or base catalysts are also used to facilitate the synthesis process.

The tetraethyl orthosilicate (TEOS) factory typically requires chemical reactors, distillation units, condensers, storage tanks, filtration systems, and drying equipment. Additional safety and control instruments are essential due to the handling of volatile chemicals.

The main steps generally include:

-

Sourcing of raw materials

-

Hydrolysis and alcoholysis reaction

-

Distillation and purification

-

Cooling and condensation

-

Storage and packaging

-

Quality testing

Usually, the timeline can range from 12 to 36 months to start a tetraethyl orthosilicate (TEOS) production plant, depending on factors like the complexity of the chemical process, procurement and installation of specialized equipment, regulatory clearances, and commissioning activities.

Challenges may include high capital requirements, securing regulatory approvals, ensuring raw material supply, competition, skilled manpower availability, and managing operational risks.

Typical requirements include business registration, environmental clearances, factory licenses, fire safety certifications, and industry-specific permits. Local/state/national regulations may apply depending on the location.

The top tetraethyl orthosilicate (TEOS) producers are:

- Evonik

- Wacker

- Momentive

- Suzhou Jinhong Gas

- Khimprom

- Dockweiler Chemicals

Profitability depends on several factors including market demand, production efficiency, pricing strategy, raw material cost management, and operational scale. Profit margins usually improve with capacity expansion and increased capacity utilization rates.

Cost components typically include:

-

Land and Infrastructure

-

Machinery and Equipment

-

Building and Civil Construction

-

Utilities and Installation

-

Working Capital

Break even in a tetraethyl orthosilicate (TEOS) production business typically range from 3 to 5 years, depending on initial capital investment, market demand, production scale, and operational efficiency. Strategic partnerships and market positioning can accelerate profitability.

Governments may offer incentives such as capital subsidies, tax exemptions, reduced utility tariffs, export benefits, or interest subsidies to promote manufacturing under various national or regional industrial policies.

Financing can be arranged through term loans, government-backed schemes, private equity, venture capital, equipment leasing, or strategic partnerships. Financial viability assessments help identify optimal funding routes.

Inquire Before Buying

Inquire Before Buying

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Request Customization

Request Customization