3D Printing Market Size, Share, Trends and Forecast by Technology, Process, Material, Offering, Application, End-User, and Region, 2025-2033

3D Printing Market Size and Share:

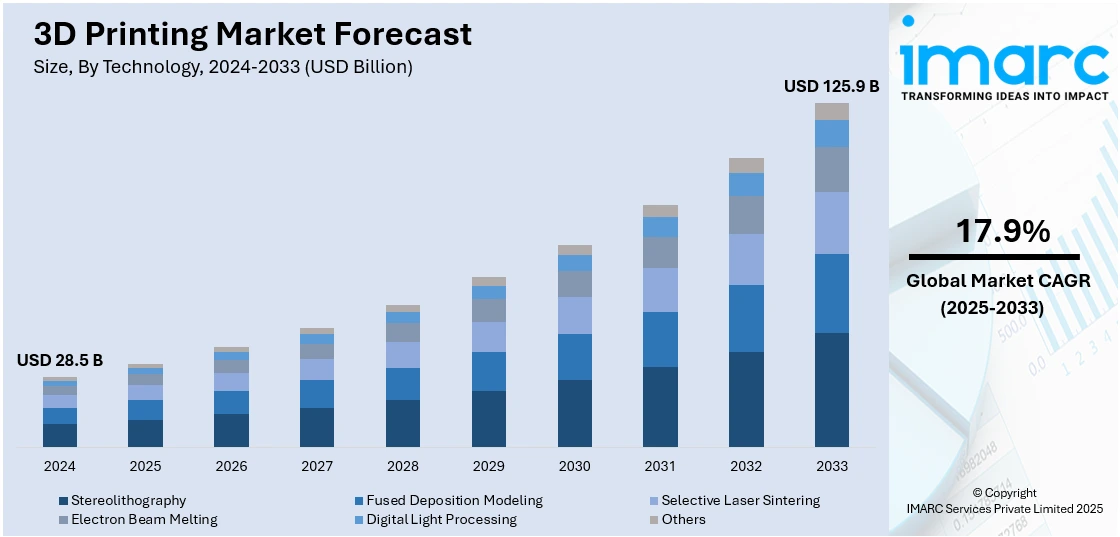

The global 3D printing market size was valued at USD 28.5 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 125.9 Billion by 2033, exhibiting a CAGR of 17.9% during 2025-2033. North America currently dominates the market, holding a significant market share of over 33.8% in 2024. The market is primarily influenced by the continual advancements in AI-powered 3D printing technologies, increasing reliance on personalized solutions in numerous end-use industries, rising adoption of sustainable manufacturing methods, and strategic government initiatives facilitating additive manufacturing.

| Report Attribute | Key Statistics |

|---|---|

|

Base Year

|

2024 |

|

Forecast Years

|

2025-2033 |

|

Historical Years

|

2019-2024

|

|

Market Size in 2024

|

USD 28.5 Billion |

|

Market Forecast in 2033

|

USD 125.9 Billion |

| Market Growth Rate (2025-2033) | 17.9% |

The global 3D printing market is mainly influenced by the shifting trend toward more sustainable practices that align with global sustainability goals, which fuels the development of the market. Continual technological advancements in both hardware and software, including integration with artificial intelligence (AI) and machine learning (ML), enhance design accuracy and improve the operation's efficiency. According to industry reports on August 29, 2024, researchers at Washington State University have developed an AI algorithm that enhances 3D printing efficiency for complex structures. This AI employs Bayesian Optimization to determine optimal printing settings, improving the production of intricate models such as artificial organs and flexible electronics. The algorithm's ability to learn and refine printing parameters reduces time, cost, and labor in manufacturing detailed 3D-printed models. Furthermore, the increasing application of 3D printing in the education sector, as it enhances the quality of subjective illustrations and makes complicated thoughts easier to understand, positively impacts market growth. Besides this, 3D printing provides different benefits, including flexibility, eco-friendliness, and rapid prototyping, contributing to the growth of the market.

The United States stands out as a key regional market, which is witnessing substantial growth due to the widespread adoption of additive manufacturing in industries such as aerospace, healthcare, and automotive. The country's robust research and development (R&D) infrastructure is fostering continuous innovation in printing technologies and materials, further propelling the market forward. For example, America Makes announced a USD 2.1 million open project call to advance additive manufacturing technologies on June 19, 2024. This project is funded by The Office of the Under Secretary of Defense, Research and Engineering Manufacturing Technology Office (OSD (R&E)). The initiative focuses on six key areas, including in-situ dimensional verification, sensor calibration, material property characterization, cost-effective aluminum manufacturing, residual stress prediction in laser powder bed fusion, and sustainable practices in additive manufacturing. Moreover, significant government support, including grants and tax incentives, is encouraging businesses to adopt 3D printing for advanced manufacturing. The availability of a well-established supply chain and strong industry collaborations is providing businesses with easy access to advanced 3D printers and materials, further increasing adoption.

3D Printing Market Trends:

Advancements in Material Development

Innovative materials play a very important role in the development of the 3D printing market. Manufacturers are introducing more advanced materials with improved properties, such as tensile strength, resistance to heat, and flexibility. High-performance materials expand the application scope in varied industries, from aerospace and healthcare. The market is embracing sustainability through bio-based materials, thereby opening avenues for environmentally conscious manufacturing sectors. For instance, a 2024 research paper by Clara Vazquez-Martel et al. discusses "Printing Green," a novel 3D printing approach utilizing microalgae-based materials. This method integrates living microalgae into printable bio-inks, enabling the fabrication of environmentally friendly structures with potential applications in sustainable manufacturing and biotechnology. The study underscores the potential of combining biological organisms with advanced manufacturing techniques to develop eco-friendly materials. Advancement in material science increases 3D printing market share because industries, as industries adopt the technology to reduce costs and improve efficiency in production processes. Material customization also opens the chance for businesses to tailor solutions that improve customer satisfaction and promote innovation.

Expansion of Industrial Applications

3D printing is gradually being adopted by industries where tasks require precision, waste reduction, and rapid prototyping. Automotive and aerospace companies prefer additive manufacturing for lightweight part creation, while healthcare uses this for customized medical devices. The increasing utilization of 3D printing in the automotive industry to manufacture prototypes and various functional parts represents one of the major factors influencing the market positively. According to reports, automotive OEMs are expected to invest USD 323 Billion in EVs by 2070, generating USD 9.6 Trillion in revenues, driving demand for 3D printing. This versatility has a high impact on the 3D printing market size. The technology's ability to deliver intricate designs without requiring complex tooling drives its appeal. The fashion and consumer electronics industries also adopt 3D printing to create customized product lines. The scalability of these applications accelerates growth, appealing to large-scale manufacturers and small businesses.

Rise of Customization and On-Demand Production

Customization and on-demand production have revolutionized the way business' function, enabling them to fulfil consumer needs with precision. The growing adoption of 3D printing in the healthcare industry to produce customized hearing aid shells, braces, and tooth implants is offering a favourable market outlook. For instance, Indian private equity and venture capital investments in the hospital sector surged from USD 2.8 Billion in 2020 to USD 6 Billion in 2021, highlighting increased funding opportunities. This growth is driving advancements in 3D printing for healthcare applications, enhancing innovation and patient care. Companies use these capabilities to provide fast solutions in competitive markets. In addition, current 3D printing market trends on decentralized manufacturing highlight that products are produced at local facilities closer to the end-user, reducing shipping costs and lead times. This flexibility also resonates with sustainable business practices, thereby leading to wide adoption and driving growth in the market.

3D Printing Industry Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the global 3D printing market, along with forecasts at the global and regional levels from 2025-2033. The market has been categorized based on technology, process, material, offering, application, and end-user.

Analysis by Technology:

- Stereolithography

- Fused Deposition Modeling

- Selective Laser Sintering

- Electron Beam Melting

- Digital Light Processing

- Others

Stereolithography technology has a very high precision with an excellent surface finish. This technology can be ideal for creating prototypes, molds, and medical devices that demand very intricate detail. Stereolithography is significant for health care and jewelry industries, as it provides very precise parts with smooth finishes.

Fused deposition modeling is one of the most accessible and widely used technologies in 3D printing. This technology is appropriate for prototyping, functional testing, and low-volume production through the extrusion of thermoplastic materials layer by layer. It is a very affordable and compatible technology that is commonly used in education, small businesses, and the automotive industry, which often require cost-effective solutions.

Selective laser sintering plays a very crucial role in developing durable and complex parts without requiring any support structure. In this technique, the sintering of powdered materials like nylon or metal is done layer by layer through a laser. This technology is utilized in aerospace, automotive, and industrial sectors. Its relevance in high-performance manufacturing, its efficiency in functional prototypes, and end-use part development enhances its importance.

Analysis by Process:

- Binder Jetting

- Directed Energy Deposition

- Material Extrusion

- Material Jetting

- Powder Bed Fusion

- Sheet Lamination

- Vat Photopolymerization

Binder Jetting leads the market 2024. Binder jetting is a crucial process due to its unique method of producing complex geometries with precision and scalability. By means of an additive manufacturing technique, it employs a liquid binding agent to hold powdered materials together layer by layer to achieve geometrical configurations that could not be attained using conventional manufacturing techniques. It is compatible with several materials from metals, ceramics, and sand, appropriate for multiple sectors, including automobile parts, aerospace, and healthcare. One of the major benefits of binder jetting is that it requires no support structures, limited material waste, and faster production. This process also aids in the production of parts that can have customized properties like porosity and density. With more emphasis being directed toward sustainable and efficient manufacturing, binder jetting is gaining further momentum in the 3D printing market.

Analysis by Material:

- Photopolymers

- Plastics

- Metals and Ceramics

- Others

Photopolymers leads the market 2024. Photopolymers are a class of materials that can be categorized into high-performance, versatile types, which are used extensively in resin-based technologies such as stereolithography and digital light processing. Photopolymers are very fast-acting and cured under ultraviolet light. They enable detailed layer-by-layer construction of the products with smooth surface finishes. This material has many applications in industries like healthcare, dentistry, and consumer goods. The ability to achieve high resolution and accuracy makes photopolymers important in the production of intricate prototypes, functional parts, and molds. Photopolymers have several mechanical and thermal properties that could be adapted to various demands, such as flexibility, strength, or biocompatibility. New formulations of photopolymers are being developed in material science, expanding their applications to include high-temperature resistance and improved toughness.

Analysis by Offering:

- Printer

- Material

- Software

- Service

Printer leads the market in 2024. Printers are the primary interface that translates digital designs into physical objects. They are used in diverse industries, such as automobiles and aerospace, healthcare, and consumer goods. The capability for high precision, material versatility, and scalability makes modern 3D printers suitable for use in prototyping and large-scale production. Advanced features like multi-material printing, faster build speeds, and higher resolution enable the production of complex geometries and highly customized parts. As technology develops further, innovations in the 3D printer are increasing, thereby solidifying the position within the 3D printing market.

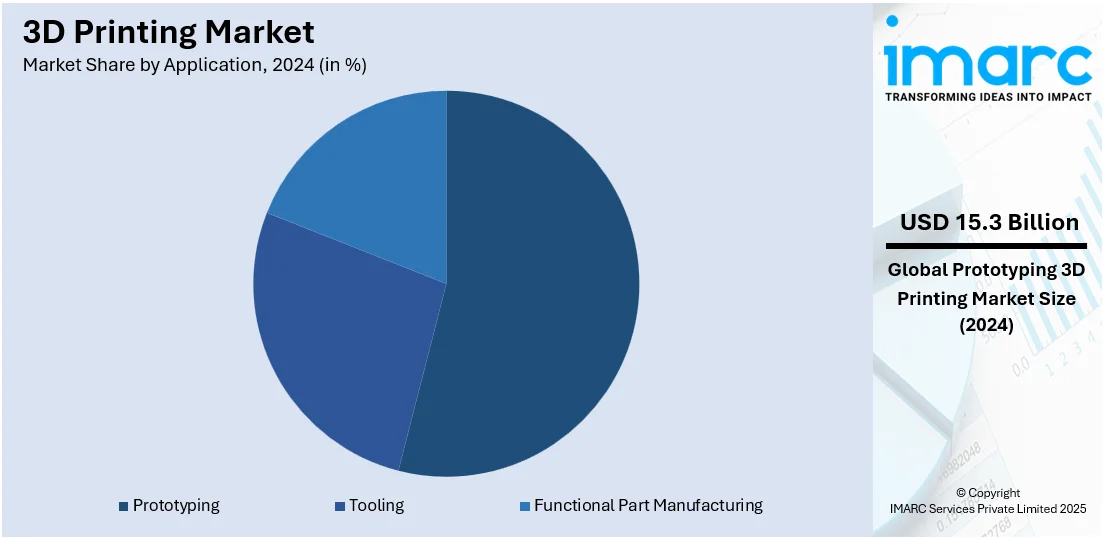

Analysis by Application:

- Prototyping

- Tooling

- Functional Part Manufacturing

Prototyping leads the market with around 53.7% of market share in 2024. Prototyping is primarily the first application in 3D printing, which encourages the innovative advancement of industries by means of rapid, yet inexpensive, new product development. It allows designers and engineers to produce physical models directly from digital design. Prototyping using 3D printing offers unparalleled flexibility, which makes it easier to test and refine concepts, identify design flaws, and implement changes with minimal time and expense. It supports industries such as automotive, aerospace, healthcare, and consumer goods by providing high-precision models that can emulate both the functionality and aesthetics of end products. The ability to create prototypes with complex geometries and varied materials with exceptional accuracy enhances innovation while accelerating the market launch for new products.

Analysis by End User:

- Consumer Products

- Machinery

- Healthcare

- Aerospace

- Automobile

- Others

Consumer products lead the market in 2024. Consumer products are one of the major areas of application for the 3D printing market. From customized accessories and personal household items to wearable tech and lifestyle products, 3D printing enables an individual to design products with exclusive designs according to their requirements. This sector benefits from the cost-effectiveness and speed of 3D printing because manufacturers can experiment with prototypes, produce limited editions, and reduce waste by using the required amounts of material. The integration of technology and design demonstrates how 3D printing is transforming the consumer landscape with efficient and flexible manufacturing solutions.

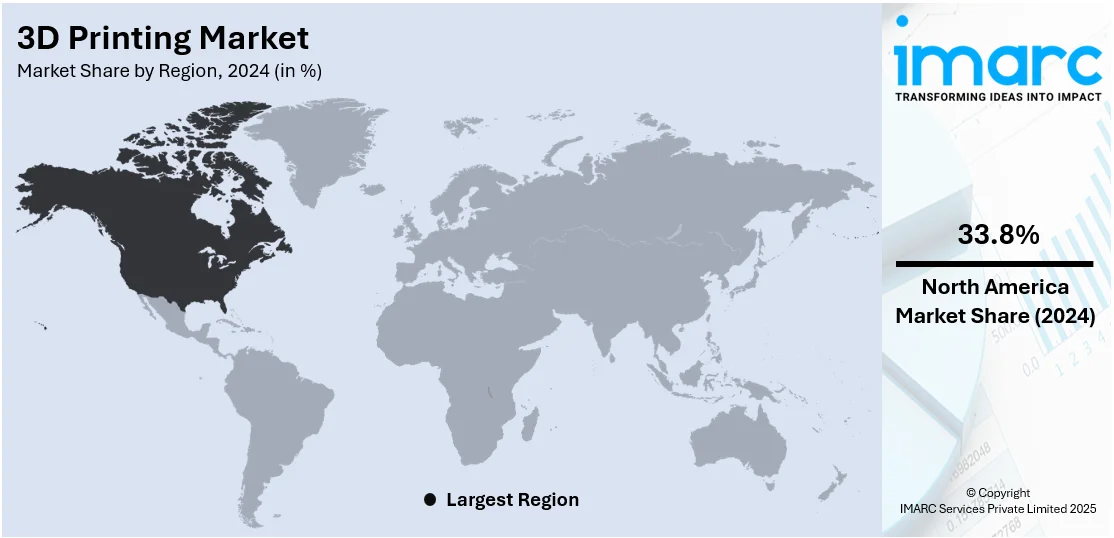

Regional Analysis:

- Europe

- North America

- Asia Pacific

- Middle East and Africa

- Latin America

North America accounted for the largest market share of over 33.8% in 2024. North America plays a significant part in the 3D printing market due to technology bases, a robust industrial presence, and an emphasis on innovation. It has large numbers of renowned manufacturers, research houses, and technology start-ups that keep testing the limits of additive manufacturing. Government support through funding and initiatives targeted at the promotion of advanced manufacturing further boosts the market in the region. High investment in research and development (R&D) activities by key players enhances the competitive edge of the region. The growing adoption of 3D printing in educational institutions and small-to-medium enterprises also depicts its broad appeal. North America's commitment to sustainability and efficiency continues to shape its leadership in the global 3D printing market.

Key Regional Takeaways:

United States 3D Printing Market Analysis

The expanding applications of 3D printing in the defense sector in the United States are supporting the market growth. For instance, the U.S. military's defense spending increased by 62% since 1980, reaching USD 820 Billion in 2023, with a 2.6% budget increase for 2024 driving investments in advanced technologies like 3D printing for enhanced defense capabilities. The ability to produce lightweight, robust, and customized components on demand is driving interest. This technology supports rapid prototyping, enabling faster development of equipment while reducing production costs. Additionally, the efficiency of additive manufacturing in creating intricate designs enhances operational capabilities. Its application in defense extends to creating complex geometries for weapon systems, reducing waste, and shortening supply chains. The technology also caters to maintenance needs, allowing precise replacements for damaged parts, improving readiness and reducing downtime. The push towards sustainability in the United States further underscores its importance, as 3D printing uses fewer materials, supporting environmentally friendly manufacturing.

Asia Pacific 3D Printing Market Analysis

The Asia Pacific region is using 3D printing technology to fuel innovation and efficient production. The regional automobile industry is embracing 3D printing to enhance productivity, efficiency, and customization. According to India Brand Equity Foundation, In FY24, the Indian automobile industry grew by 19% to USD 122.53 Billion. The technology allows the creation of intricate designs for vehicle components, reducing assembly complexity. Its use in rapid prototyping accelerates the development of new models, cutting time-to-market. Lightweight materials manufactured through additive processes improve fuel efficiency and performance, aligning with sustainability goals. In Asia Pacific, 3D printing empowers manufacturers to pursue innovative designs and creative solutions, increasing the appeal of vehicles in competitive markets. The technology minimizes tooling expenses and material wastage, driving broader adoption across the region. It also facilitates the efficient production of limited runs and customized components, addressing specific consumer needs. By fostering advancements in electric and autonomous vehicles, additive manufacturing continues to reshape the automobile industry.

Europe 3D Printing Market Analysis

In Europe, the aerospace sector highly prioritizes 3D printing for its unmatched precision, dependability, and efficient material usage. This technology supports the creation of complex geometries essential for producing lighter and more durable components. According to reports, in 2023, Europe's aerospace and defense turnover grew by 10.1% to approximately USD 307.3 Billion. The rise reflects increased adoption of 3D printing technologies driving innovation and efficiency of aircrafts by prototyping. Reduced weight enhances fuel efficiency and operational performance, crucial for long-term cost savings. Additive manufacturing also reduces lead times for parts production, ensuring timely delivery and maintenance schedules. By minimizing material wastage, it aligns with the sustainability objectives of the country. This process is pivotal for creating highly specialized parts, including turbine blades and engine components. The ability to streamline production and test innovative designs further bolsters its adoption in Europe. Additionally, 3D printing ensures efficient use of resources while maintaining high safety and quality standards.

Latin America 3D Printing Market Analysis

Inflating disposable incomes and the growing preference for personalized products in the Latin America are driving the adoption of 3D printing. For instant, Latin America's total disposable income is projected to grow by nearly 60% in real terms from 2021 to 2040. This rise, driven by economic shifts and technological advancements, is fueling the adoption of 3D printing for personalized product designing. 3D printing technology caters to customization demands in consumer goods, such as fashion accessories and home décor, by enabling intricate designs and tailored production. Additionally, it supports efficient prototyping for startups and small-scale manufacturers, reducing costs and time. 3D printing's ability to meet diverse industry needs through its flexibility and affordability enhances its relevance. This trend in Latin America is further amplified by increasing access to advanced technologies, which democratizes manufacturing capabilities across different sectors.

Middle East and Africa 3D Printing Market Analysis

The expansion of infrastructure and the healthcare sector in the Middle East and Africa region is propelling the adoption of 3D printing. According to Dubai Healthcare City Authority report, Dubai’s healthcare sector is expanding rapidly, with 4,482 private medical facilities and over 55,208 licensed professionals as of 2022. Projected growth of 10-15% for professionals and 3-6% for facilities is driving 3D printing adoption for personalized medical products, capitalizing on innovation in patient care. The construction industry in the region benefits from the technology's ability to create complex structures with precision and efficiency, reducing material usage and time. In healthcare, it supports the production of personalized implants, prosthetics, and surgical tools, enhancing patient outcomes. The technology's cost-effective approach enables wider accessibility, meeting the demands of growing urbanization. Additionally, 3D printing facilitates innovative solutions across industries, ensuring its integration into diverse applications.

Competitive Landscape:

The 3D printing market is highly competitive due to constant innovation in technology as well as its diverse applications in several industries. Key players in the market focus on innovations in the materials, hardware, and software that are used to boost performance and improve cost efficiency in products. Increased adoption in the sector in health, automotive, aerospace, and manufacturing fuels need for customized solutions. Startups and existing manufacturers are using research and development (R&D) activities to introduce cutting-edge technologies, while partnerships and acquisitions are common strategies to expand market presence.

The report provides a comprehensive analysis of the competitive landscape in the 3D printing market with detailed profiles of all major companies, including:

- 3D Systems Inc.

- Beijing Tiertime Technology Corporation Limited

- EOS GmbH

- The ExOne Company (Desktop Metal Inc.)

- General Electric Company

- Hewlett Packard Enterprise Company

- Materialise NV

- Optomec Inc.

- Proto Labs Inc.

- Renishaw Plc

- SLM Solutions Group AG

- Stratasys Limited

- Ultimaker B.V.

- Voxeljet AG

- XYZprinting Inc.

Latest News and Developments:

- December 2024: BMW has implemented a fully automated 3D printing line, developed by Laempe Mössner Sinto GmbH, at its Landshut foundry for sand core production. This high-volume system, created in collaboration with R. Scheuchl GmbH, includes six 3D printers, measurement tools, and core removal solutions. It supports the production of molds for BMW's new six-cylinder engines. The innovation highlights advanced manufacturing in the automotive industry.

- December 2024: Stratasys has become NASCAR's exclusive 3D printing partner under a multi-year agreement. The collaboration will leverage Stratasys technology to design and produce parts, tools, and enhance driver performance. Key innovations include 3D-printed ducts for cooling drivers during races. This marks a significant step in integrating advanced manufacturing into motorsports.

- December 2024: ETH spin-off a-metal has launched a compact, affordable metal L-PBF 3D printer designed for SMEs. The innovative system features powder cartridges mounted directly on the recoating unit for clean and safe operation. This user-friendly solution aims to bridge the accessibility gap in metal 3D printing. It marks a significant step forward in democratizing additive manufacturing for smaller businesses.

- November 2024: Prusa Research unveiled the CORE One 3D printer at Formnext, marking a major advancement for the company. Designed for professionals and newcomers, it boasts faster speeds and a 30% smaller, compact design. The open-system printer supports modifications and upgrades, aligning with Prusa's commitment to versatility. A Conversion Kit allows MK4S users to upgrade seamlessly.

- November 2024: Impossible Objects has launched the CBAM 25, the world’s fastest 3D printer, in Europe, revolutionizing additive manufacturing. The CBAM 25 uses advanced composite materials to produce stronger, cost-efficient parts at speeds suited for mass production. Founder Robert Swartz highlights its ability to rival CNC machining in quality and throughput. The launch follows the printer's global debut in June.

3D Printing Market Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Billion USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Technologies Covered | Stereolithography, Fused Deposition Modeling, Selective Laser Sintering, Electron Beam Melting, Digital Light Processing, Otherslk, Buffalo Milk, Goat Milk, Others |

| Processes Covered | Binder Jetting, Directed Energy Deposition, Material Extrusion, Material Jetting, Power Bed Fusion, Sheet Lamination, Vat Photopolymerization |

| Materials Covered | Photopolymers, Plastics, Metals and Ceramics, Others |

| Offerings Covered | Printer, Material, Software, Service |

| Applications Covered | Prototyping, Tooling, Functional Part Manufacturing |

| End Users Covered | Consumer Products, Machinery, Healthcare, Aerospace, Automobile, Others |

| Region Covered | Asia Pacific, Europe, North America, Latin America, Middle East and Africa |

| Companies Covered | 3D Systems Inc., Beijing Tiertime Technology Corporation Limited, EOS GmbH, The ExOne Company (Desktop Metal Inc.), General Electric Company, Hewlett Packard Enterprise Company, Materialise NV, Optomec Inc., Proto Labs Inc., Renishaw Plc, SLM Solutions Group AG, Stratasys Limited, Ultimaker B.V., Voxeljet AG and XYZprinting Inc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the 3D printing market from 2019-2033.

- The 3D printing market research report provides the latest information on the market drivers, challenges, and opportunities in the global market.

- The study maps the leading, as well as the fastest-growing, regional markets. It further enables stakeholders to identify the key country-level markets within each region.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the 3D printing industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from digital designs by layering materials. This innovative technology is widely used across industries like healthcare, aerospace, and automotive due to its ability to produce complex, customized, and lightweight components efficiently.

The global 3D printing market was valued at USD 28.5 Billion in 2024.

IMARC estimates the global 3D printing market to exhibit a CAGR of 17.9% during 2025-2033.

The key factors driving the global 3D printing market include advancements in material science, the expansion of industrial applications, and increasing need for customization and on-demand manufacturing.

According to the report, binder jetting represented the largest segment by process, driven by the growing demand for high-speed production and complex designs.

According to the report, photopolymers represented the largest segment by material, driven by the need for superior accuracy, smooth finishes, and detailed prototypes.

According to the report, printers represented the largest segment by offering, driven by technological advancements and rising affordability for industrial and consumer usage.

According to the report, prototyping represented the largest segment by application with a market share of 53.7%, driven by the need for faster design iterations and cost-effective product development.

According to the report, consumer products represented the largest segment by end-user, driven by the demand for customized and innovative designs in everyday items.

On a regional level, the market has been classified into Europe, North America, Asia Pacific, Middle East and Africa, and Latin America, wherein North America currently dominates the global market.

Some of the major players in the global 3D printing market include 3D Systems Inc., Beijing Tiertime Technology Corporation Limited, EOS GmbH, The ExOne Company (Desktop Metal Inc.), General Electric Company, Hewlett Packard Enterprise Company, Materialise NV, Optomec Inc., Proto Labs Inc., Renishaw Plc, SLM Solutions Group AG, Stratasys Limited, Ultimaker B.V., Voxeljet AG and XYZprinting Inc., among others.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)