Australia 3D Printing Materials Market Size, Share, Trends and Forecast by Type, Form, End User, and Region, 2025-2033

Australia 3D Printing Materials Market Size and Share:

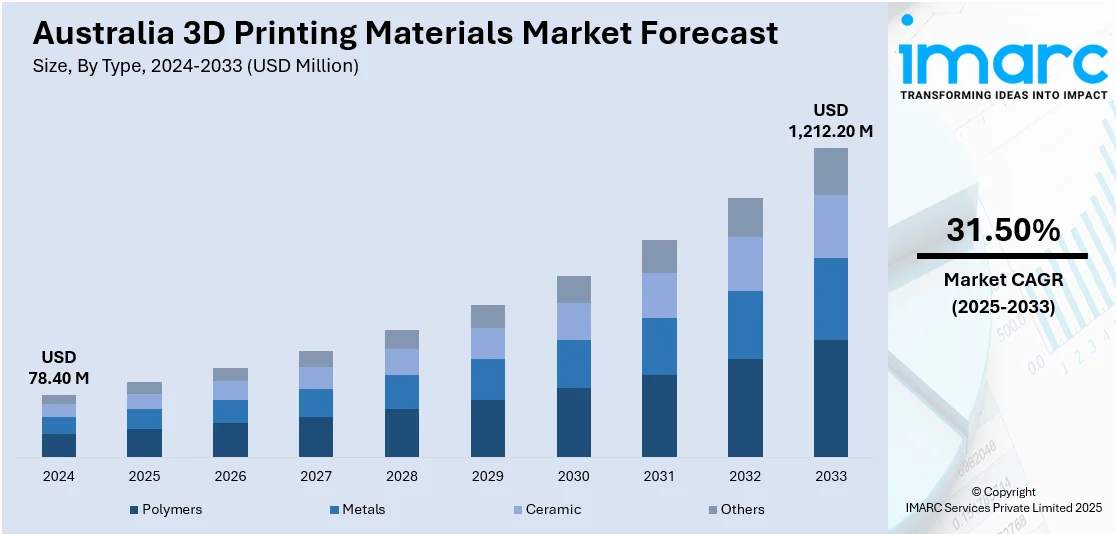

The Australia 3D printing materials market size reached USD 78.40 Million in 2024. Looking forward, IMARC Group expects the market to reach USD 1,212.20 Million by 2033, exhibiting a growth rate (CAGR) of 31.50% during 2025-2033. The market is driven by the growing adoption of additive manufacturing in the aerospace, healthcare, and automotive industries in Australia. Moreover, the increasing demand for lightweight and bespoke components and advances in material technology, metal powders, and biocompatible polymers are supporting the growth of the market. Also, government programs and research and development (R&D) initiatives spearheaded by universities are creating advanced 3D printing materials appropriate for local industry demands, further augmenting the Australia 3D printing materials market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024 |

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 78.40 Million |

| Market Forecast in 2033 | USD 1,212.20 Million |

| Market Growth Rate 2025-2033 | 31.50% |

Key Trends of Australia 3D Printing Materials Market:

Growth in Demand for Metal 3D Printing Materials

Metal 3D printing material demand in Australia is increasing strongly, driven by advancements in aerospace, automotive, and medical sectors. Metal 3D printing enables the production of complicated geometries that are challenging or unachievable in traditional manufacturing, resulting in cost-efficient, high-performance products. Within the automotive industry, manufacturers are increasingly using metal 3D printing as a means of rapid prototyping and manufacturing lightweight, long-lasting components. This trend aligns with the significant growth in the automotive industry in Australia, which attained a record-breaking milestone in 2023, with 1,216,780 vehicles delivered, exceeding records for new car sales. With increasing demand for innovative car solutions, metal 3D printing is now a leading manufacturing technique for producing quality functional parts with improved accuracy. This surge in automotive production is further driving the need for advanced metal printing materials that can meet the performance and durability requirements of the industry. The medical industry is also using metal 3D printing for customized prosthetics and implants. In addition to this, research in additive manufacturing and the development of novel metal alloys tailored for 3D printing are also stimulating market demand.

To get more information on this market, Request Sample

Increased Use of Bio-Based and Sustainable 3D Printing Materials

In accordance with global sustainability trends, there is growing demand for eco-friendly and bio-based 3D printing materials in Australia. As businesses attempt to shrink their carbon footprint and make themselves more eco-friendly, bio-based threads manufactured from renewable feedstock like PLA (polylactic acid) and PHA (polyhydroxyalkanoates) are gaining traction. The materials present a biodegradable alternative to typical petroleum-based plastics and hence are suitable for a variety of uses that vary from packaging and product development to consumer products. Besides this, research institutions and companies are exploring new materials that are derived from agricultural waste, such as hemp and algae-based filaments, which can be used in 3D printing without contributing to environmental degradation. The demand for sustainable products and government incentives for sustainable manufacturing are the major drivers for the Australia 3D printing materials market growth.

Advancements in High-Performance Polymers for Industrial Applications

The utilization of high-performance polymers within the market, especially in industrial applications is positively impacting the market development. These compounds, including PEEK (polyetheretherketone), PEI (polyetherimide), and ULTEM, have outstanding mechanical characteristics, such as high temperature stability, chemical resistance, and strength, which makes them suitable for industries that need strong materials for crucial applications. Sectors such as aerospace, automotive, and electronics are adopting high-performance polymers to produce components that withstand harsh operating conditions. The application of the polymers for both prototype and end-use production is increasing their market appeal. With ongoing research into improving the processing capabilities and cost-effectiveness of these materials, their use in additive manufacturing is expected to expand further. Additionally, the growing need for functional, resistant, and light elements in premium industries is fueling the need for high-performance polymers in the marketplace.

Growth Drivers of Australia 3D Printing Materials Market:

Aerospace and Automotive Industry Expansion

Australia's automotive and aerospace industries are major drivers of the 3D printing materials market. Australia's aerospace industry is increasingly embracing additive manufacturing for high-performance and lightweight components, lowering the costs of production and increasing efficiency. Innovative metal powders and composite materials are being used by domestic manufacturers to create robust parts for challenging environments. 3D printing is transforming small-batch production and prototyping in the automotive sector, enabling businesses to create complex designs more precisely. In order to comply with environmental regulations, Australian businesses are also investigating sustainable materials, which is encouraging innovation in recyclable composites and bio-based polymers. Research organizations and manufacturers are being forced to create region-specific solutions due to the growing demand for high-strength, customized materials. The country focuses more on the technological advancements, making it the hub for the advanced applications of 3D printing. This increases the demand for the specialized materials that are used to fulfill the industry's needs.

Advances in Medical and Bioprinting Technologies

The field of healthcare is the biggest driver behind the expansion of the market for Australian 3D printing materials. The nation is at the forefront of medical innovation, employing additive manufacturing to create surgical instruments, implants, and prosthetics. Hospitals and research centers are working together to create metal alloys and biocompatible polymers that improve patient outcomes. The development of tissue scaffolds and applications in regenerative medicine are made possible by the growing demand for specialized materials brought on by the growth of bioprinting. Universities and biotech companies in Australia are leading the way in developing novel formulations that meet the particular requirements of the medical sector while guaranteeing adherence to strict safety regulations. A self-sustaining ecosystem for cutting-edge healthcare solutions is also being fostered by the drive for localized production, which is lowering reliance on imported medical components. The creation of high-performance 3D printing materials is still a top priority as the industry develops, helping to advance precision and personalized medicine.

Government Initiatives and Research Investments

Australia's government plays a crucial role in driving the 3D printing materials market through funding and policy support. Different programs promote local fabrication and innovation, furthering the creation of new materials appropriate for additive manufacturing. Research facilities are granted funding for discovery of new composition of materials, with emphasis on sustainability and performance improvement. The nation's dedication to minimizing environmental footprint has moved more investment towards biodegradable and recyclable 3D printing materials. Furthermore, partnerships between academic institutions and business titans are encouraging the commercialization of innovative materials and guaranteeing their incorporation into conventional manufacturing. By providing the raw materials for premium metal powders used in additive manufacturing, the mining industry also contributes. With a focus on technological advancement, Australia keeps improving its material science methodology to keep its 3D printing sector competitive worldwide. These initiatives taken together will shape the region's advanced manufacturing landscape going forward.

Australia 3D Printing Materials Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional levels for 2025-2033. Our report has categorized the market based on type, form, and end user.

Type Insights:

- Polymers

- Acrylonitrile Butadiene Styrene (ABS)

- Polylactic Acid (PLA)

- Photopolymers

- Nylon

- Others

- Metals

- Steel

- Titanium

- Aluminum

- Others

- Ceramic

- Silica Sand

- Glass

- Gypsum

- Others

- Others

The report has provided a detailed breakup and analysis of the market based on the type. This includes polymers (acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), photopolymers, nylon, and others), metals (steel, titanium, aluminum, and others), ceramic (silica sand, glass, gypsum, and others), and others.

Form Insights:

- Powder

- Filament

- Liquid

A detailed breakup and analysis of the market based on the form have also been provided in the report. This includes powder, filament, and liquid.

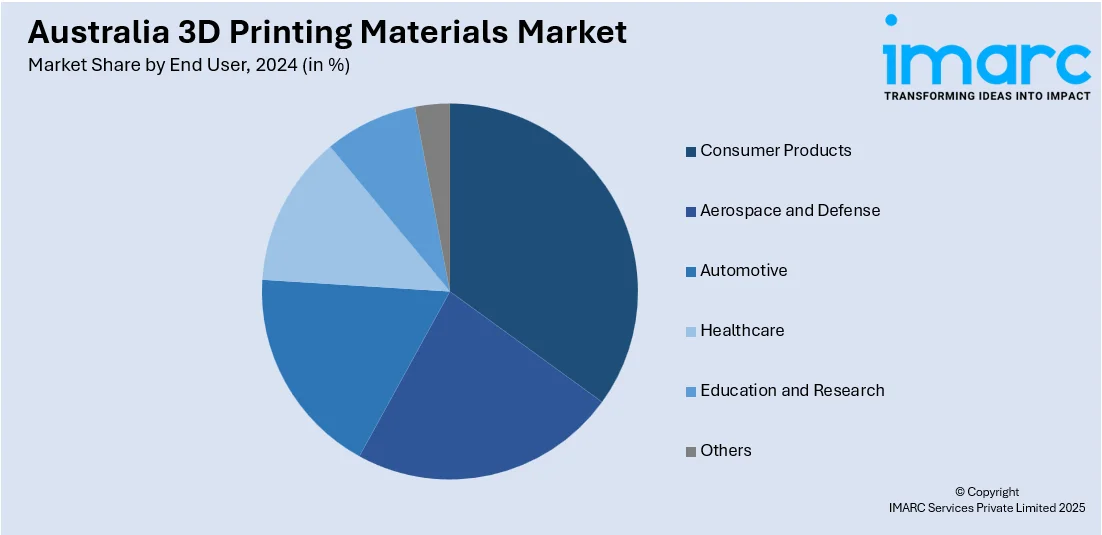

End User Insights:

- Consumer Products

- Aerospace and Defense

- Automotive

- Healthcare

- Education and Research

- Others

The report has provided a detailed breakup and analysis of the market based on the end user. This includes consumer products, aerospace and defense, automotive, healthcare, education and research, and others.

Regional Insights:

- Australia Capital Territory & New South Wales

- Victoria & Tasmania

- Queensland

- Northern Territory & Southern Australia

- Western Australia

The report has also provided a comprehensive analysis of all the major regional markets, which include Australia Capital Territory & New South Wales, Victoria & Tasmania, Queensland, Northern Territory & Southern Australia, and Western Australia.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Australia 3D Printing Materials Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Types Covered |

|

| Forms Covered | Powder, Filament, Liquid |

| End Users Covered | Consumer Products, Aerospace and Defense, Automotive, Healthcare, Education and Research, Others |

| Regions Covered | Australia Capital Territory & New South Wales, Victoria & Tasmania, Queensland, Northern Territory & Southern Australia, Western Australia |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Australia 3D printing materials market from 2019-2033.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Australia 3D printing materials market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Australia 3D printing materials industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

The Australia 3D printing materials market was valued at USD 78.40 Million in 2024.

The Australia 3D printing materials market is projected to exhibit a CAGR of 31.50% during 2025-2033.

The Australia 3D printing materials market is expected to reach a value of USD 1,212.20 Million by 2033.

The Australian 3D printing materials market is changing due to the growing demand for sustainable alternatives, bio-based polymers, and metal-based materials. Regional research initiatives and advancements in material technology are influencing the direction of additive manufacturing in the region.

The market in Australia is being driven by the increasing need for lightweight and customized components in aerospace, healthcare, and automotive industries. Moreover, research programs and government initiatives further improve local manufacturing capabilities.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)