Australia Electric Welding Equipment Market Size, Share, Trends and Forecast by Equipment, Technology, Application, and Region, 2025-2033

Australia Electric Welding Equipment Market Overview:

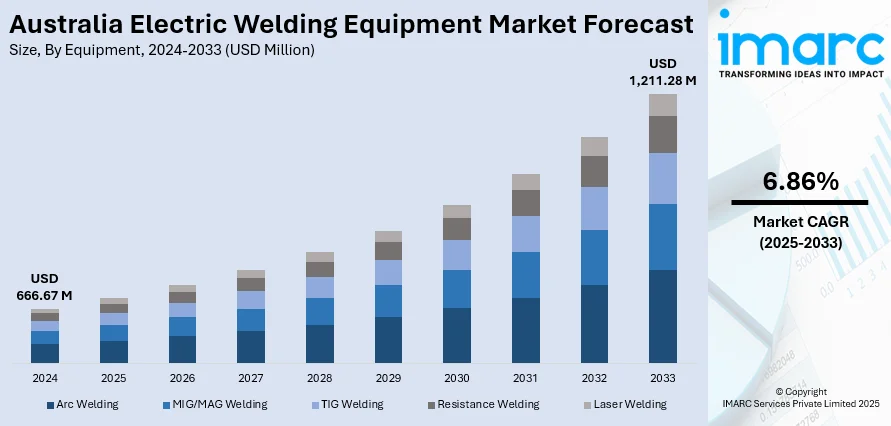

The Australia Electric Welding Equipment Market size reached USD 666.67 Million in 2024. Looking forward, IMARC Group expects the market to reach USD 1,211.28 Million by 2033, exhibiting a growth rate (CAGR) of 6.86% during 2025-2033. The market is driven by increasing infrastructure development, rising demand from the automotive and construction sectors, and the growing adoption of automation in manufacturing processes. Technological advancements, including energy-efficient and portable welding systems, further fuel market growth. Government investments in industrial development and skilled workforce training also contribute to rising equipment adoption, which is supporting the expansion of the Australia electric welding equipment market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024

|

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 666.67 Million |

| Market Forecast in 2033 | USD 1,211.28 Million |

| Market Growth Rate 2025-2033 | 6.86% |

Australia Electric Welding Equipment Market Trends:

Adoption of Robotic and Automated Welding Systems

Robot and automated welding systems are becoming increasingly popular in Australia's electric welding equipment industry because they can improve productivity, accuracy, and efficiency. Such systems are especially useful in production industries such as motor vehicle manufacturing, where there is a need for high-volume production on a continuous basis. A robotic welding system can take over the work of 7–8 manual welders, dramatically cutting cycle times and fulfilling orders faster. Automation reduces human error, provides uniform weld quality, and increases production capacity. Further, the use of robots enhances safety through a reduction of exposure of humans to dangerous conditions, including heat, fumes, and repetitive motion. As industries focus on reducing labor expenses and expanding production capacity, robotic welding systems become crucial in modern manufacturing, transforming conventional welding processes and boosting innovation in the industry.

To get more information on this market, Request Sample

Shift Towards Energy-Efficient and Eco-Friendly Equipment

The Australia welding industry is increasingly looking toward energy-saving and environmentally friendly solutions. Industry players are changing from conventional transformer-based equipment to inverter-based equipment, which save energy and lower costs. In addition to this, industry players are turning to low-fume welding materials and consumables to lower emissions and provide healthier working conditions. These measures fit into global sustainability efforts and Australia's emphasis on lowering carbon footprints in industrial processes. In addition, cutting-edge solutions such as robotic welding equipment and filtration systems are contributing to minimizing welding's contribution to the environment by as much as 50%. With increasing environmental regulations, companies are looking to optimize their processes with more energy-efficient, eco-friendly solutions, spurring enormous innovation in the welding industry in Australia. This movement best exemplifies how important sustainability is in contemporary welding practices.

Integration of Smart Technologies and Digitalization

Artificial intelligence -equipped welding robots are substantially improving productivity, with studies indicating they can be 50% more efficient compared to conventional techniques. These robots have a maximum of 95% arc-on time and work without stoppages or fatigue, leading to improved output and reduced costs of operations. This is in tune with the increasing use of intelligent technologies like AI and IoT in welding in Australia, which is transforming operations. These technologies provide real-time monitoring, predictive maintenance, and process optimization, enabling welding equipment to identify problems early, minimizing downtime and enhancing weld quality. In aerospace and automotive manufacturing industries, where accuracy is paramount, AI and IoT integration is simplifying operations and guaranteeing greater quality standards. As industries continue to adopt these digital solutions, the application of smart technologies is becoming the need of the hour for Australia electric welding equipment market growth.

Australia Electric Welding Equipment Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional level for 2025-2033. Our report has categorized the market based on equipment, technology, and application.

Equipment Insights:

- Arc Welding

- MIG/MAG Welding

- TIG Welding

- Resistance Welding

- Laser Welding

The report has provided a detailed breakup and analysis of the market based on the equipment. This includes arc welding, MIG/MAG welding, TIG welding, resistance welding, and laser welding.

Technology Insights:

- Conventional Welding

- Automated Welding

- Robotic Welding

A detailed breakup and analysis of the market based on the technology have also been provided in the report. This includes conventional welding, automated welding, and robotic welding.

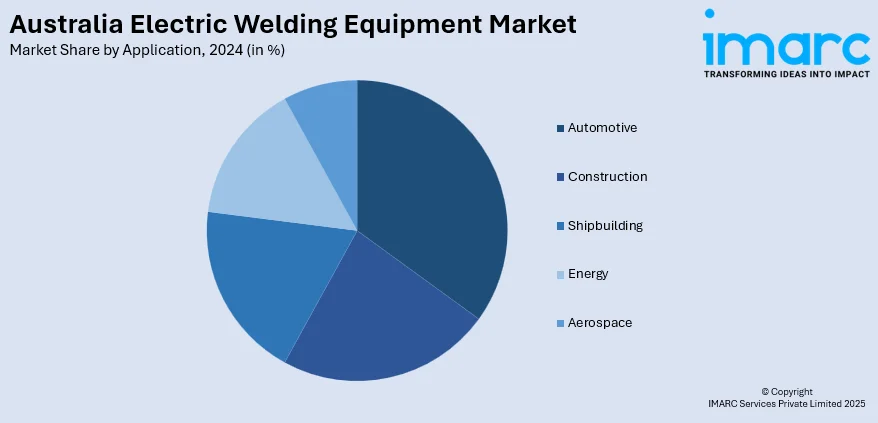

Application Insights:

- Automotive

- Construction

- Shipbuilding

- Energy

- Aerospace

The report has provided a detailed breakup and analysis of the market based on the application. This includes automotive, construction, shipbuilding, energy, and aerospace.

Regional Insights:

- Australia Capital Territory & New South Wales

- Victoria & Tasmania

- Queensland

- Northern Territory & Southern Australia

- Western Australia

The report has also provided a comprehensive analysis of all the major regional markets, which include Australia Capital Territory & New South Wales, Victoria & Tasmania, Queensland, Northern Territory & Southern Australia, and Western Australia.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Australia Electric Welding Equipment Market News:

- In April 2024, Kemppi introduced the Minarc T 223 ACDC GM, a portable multi-voltage TIG welding machine that also cleans welds. This 220 A AC/DC machine features built-in electrolytic weld cleaning, using MAX WeldClean to remove oxidation and discoloration efficiently. Key features include Auto Pulse, AC frequency control, memory channels, a large color display, and remote control options, making it ideal for high-quality welding and cleaning on-site.

- In July 2024, An AI-powered real-time vision processing system called NovEye Autonomy Gen 2 was introduced by Novarc Technologies. It completely automates pipe welding. This innovative technology improves weld quality by continuously enhancing its model through data collection. It allows the system to adapt to welding inconsistencies, ensuring X-ray quality welds with zero operator intervention. The solution, ideal for industries like aerospace and mining, also reduces human exposure to welding hazards and minimizes errors, boosting productivity.

Australia Electric Welding Equipment Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Equipments Covered | Arc Welding, MIG/MAG Welding, TIG Welding, Resistance Welding, Laser Welding |

| Technologies Covered | Conventional Welding, Automated Welding, Robotic Welding |

| Applications Covered | Automotive, Construction, Shipbuilding, Energy, Aerospace |

| Regions Covered | Australia Capital Territory & New South Wales, Victoria & Tasmania, Queensland, Northern Territory & Southern Australia, Western Australia |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Australia electric welding equipment market performed so far and how will it perform in the coming years?

- What is the breakup of the Australia electric welding equipment market on the basis of equipment?

- What is the breakup of the Australia electric welding equipment market on the basis of technology?

- What is the breakup of the Australia electric welding equipment market on the basis of application?

- What is the breakup of the Australia electric welding equipment market on the basis of region?

- What are the various stages in the value chain of the Australia electric welding equipment market?

- What are the key driving factors and challenges in the Australia electric welding equipment market?

- What is the structure of the Australia electric welding equipment market and who are the key players?

- What is the degree of competition in the Australia electric welding equipment market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Australia electric welding equipment market from 2019-2033.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Australia electric welding equipment market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Australia electric welding equipment industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)