Australia Metal Cutting Tools Market Size, Share, Trends and Forecast by Tool Type, Product Type, Application, and Region, 2025-2033

Australia Metal Cutting Tools Market Size Overview:

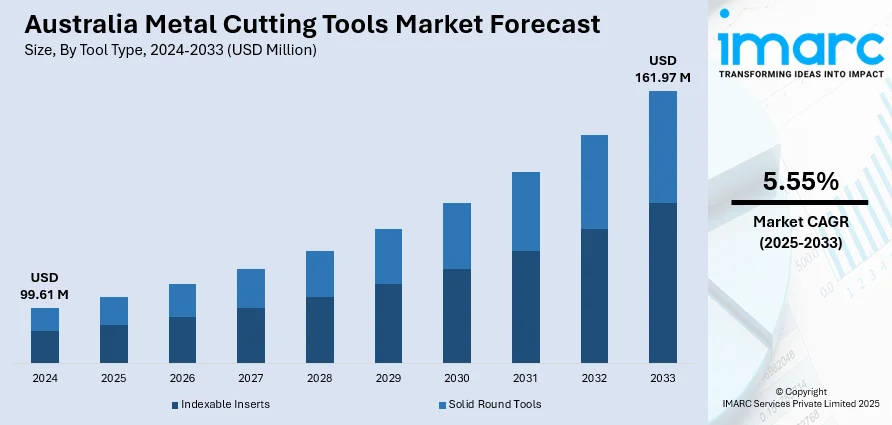

The Australia metal cutting tools market size reached USD 99.61 Million in 2024. Looking forward, IMARC Group expects the market to reach USD 161.97 Million by 2033, exhibiting a growth rate (CAGR) of 5.55% during 2025-2033. The market is driven by rising demand in aerospace, automotive, and mining sectors, increasing automation in manufacturing, and advancements in precision tooling technology. Government initiatives supporting local manufacturing and export-oriented industries further positively impact the Australia metal cutting tools market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024

|

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 99.61 Million |

| Market Forecast in 2033 | USD 161.97 Million |

| Market Growth Rate 2025-2033 | 5.55% |

Australia Metal Cutting Tools Market Trends:

Integration of Multi-Functionality in Tool Design

A key trend shaping the Australia metal cutting tools market growth is the development of multi-functional tools that combine several operations, such as drilling, milling, and turning, into one. Manufacturers are increasingly adopting such tools to enhance production flexibility and reduce tool changeovers, which leads to minimized downtime and increased throughput. This trend is particularly prevalent in industries such as precision engineering and medical device manufacturing, where complex geometries require efficient machining without compromising accuracy. As Australian manufacturers seek to reduce operational costs while maintaining high quality standards, the adoption of versatile cutting tools becomes essential. Furthermore, this aligns with lean manufacturing principles, helping companies optimise floor space and tool inventories. The move toward integrated tool capabilities is expected to accelerate, fostering further Australia metal cutting tools market growth. For instance, MAPAL Australia offers two advanced face milling tools to improve aluminium machining. The FaceMill-Diamond-ES targets smaller production runs, offering high performance and lower cost with fewer cutting edges. The NeoMill-T-Finish, using indexable inserts, enables high-efficiency finishing for large-scale production, featuring a unique insert arrangement for optimal surface quality and tool life. Both innovations support sustainability, adaptability, and productivity in sectors like automotive and aerospace.

To get more information on this market, Request Sample

Demand Surge from CNC-Based Precision Machining

A notable driver in the Australia metal cutting tools market is the increasing reliance on CNC (Computer Numerical Control) machining for high-precision component production. CNC technology allows for complex geometries and repeatability, requiring cutting tools with consistent dimensional accuracy and compatibility with high-speed operations. As sectors such as aerospace, automotive, and electronics expand their manufacturing capabilities, the need for precision tools tailored to automated systems becomes critical. Accompanying this trend is the Australian Government’s $22.7 Billion Future Made in Australia Plan, which aims to boost productivity and innovation within the nation’s manufacturing sector by investing in advanced and intelligent technologies. This strategic policy initiative fosters innovation, enhances global competitiveness, and promotes long-term industrial sustainability. Tool manufacturers are now offering digitally integrated tools with embedded sensor technologies for real-time monitoring of wear and performance. Additionally, demand for indexable inserts and modular tooling systems is rising, enabling efficient tool management and lower operational costs. This alignment with digital manufacturing practices is a cornerstone of the Australia metal cutting tools market growth.

Australia Metal Cutting Tools Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the region/country level for 2025-2033. Our report has categorized the market based on tool type, product type, and application.

Tool Type Insights:

- Indexable Inserts

- Solid Round Tools

The report has provided a detailed breakup and analysis of the market based on the tool type. This includes indexable inserts and solid round tools.

Product Type Insights:

- Lathe

- Drilling Machine

- Milling Machine

- Grinding Machine

- Others

The report has provided a detailed breakup and analysis of the market based on the product type. This includes lathe, drilling machine, milling machine, grinding machine, and others.

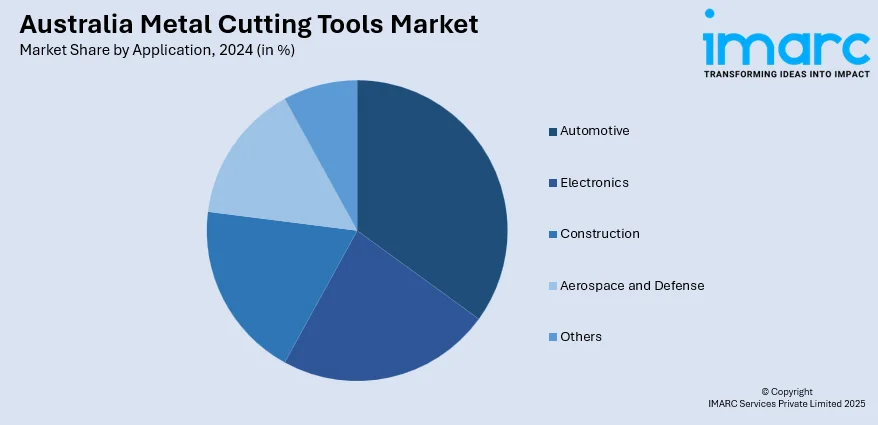

Application Insights:

- Automotive

- Electronics

- Construction

- Aerospace and Defense

- Others

The report has provided a detailed breakup and analysis of the market based on the application. This includes automotive, electronics, construction, aerospace and defense, and others.

Regional Insights:

- Australia Capital Territory & New South Wales

- Victoria & Tasmania

- Queensland

- Northern Territory & Southern Australia

- Western Australia

The report has also provided a comprehensive analysis of all the major regional markets, which include Australia Capital Territory & New South Wales, Victoria & Tasmania, Queensland, Northern Territory & Southern Australia, and Western Australia.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Australia Metal Cutting Tools Market News:

- In February 2025, Stealth Group Holdings entered into exclusive distribution agreements with global manufacturer Positec to supply CAT® Power Tools, Wesco Power Tools, and Harden Hand Tools across Australia and New Zealand. Spanning three to five years, these deals expand Stealth’s portfolio of high-margin products across diverse sales channels.

- In September 2024, ANCA announced a strategic partnership with Tetralytix to integrate their CIM3D tool verification software with Tetralytix’s Toolyzer simulation platform. This collaboration enables faster, more cost-effective virtual cutting tool design, reducing development time and manual processes. The combined solution allows users to analyze tool performance before physical testing, supporting innovation and improved efficiency. The partnership reflects ANCA’s continued leadership in digital manufacturing and aims to revolutionize precision cutting tool development through advanced simulation and modelling capabilities.

Australia Metal Cutting Tools Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Tool Types Covered | Indexable Inserts Tools, Solid Round Tools |

| Product Types Covered | Lathe, Drilling Machine, Milling Machine, Grinding Machine, Others |

| Applications Covered | Automotive, Electronics, Construction, Aerospace and Defense, Others |

| Regions Covered | Australia Capital Territory & New South Wales, Victoria & Tasmania, Queensland, Northern Territory & Southern Australia, Western Australia |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Australia metal cutting tools market performed so far and how will it perform in the coming years?

- What is the breakup of the Australia metal cutting tools market on the basis of tool type?

- What is the breakup of the Australia metal cutting tools market on the basis of product type?

- What is the breakup of the Australia metal cutting tools market on the basis of application?

- What is the breakup of the Australia metal cutting tools market on the basis of region?

- What are the various stages in the value chain of the Australia metal cutting tools market?

- What are the key driving factors and challenges in the Australia metal cutting tools market?

- What is the structure of the Australia metal cutting tools market and who are the key players?

- What is the degree of competition in the Australia metal cutting tools market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Australia metal cutting tools market from 2019-2033.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Australia metal cutting tools market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Australia metal cutting tools industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)