Australia Thermal Processing Equipment Market Size, Share, Trends and Forecast by Equipment Type, Process Type, Heating Source, Automation Level, End Use Industry, and Region, 2025-2033

Australia Thermal Processing Equipment Market Overview:

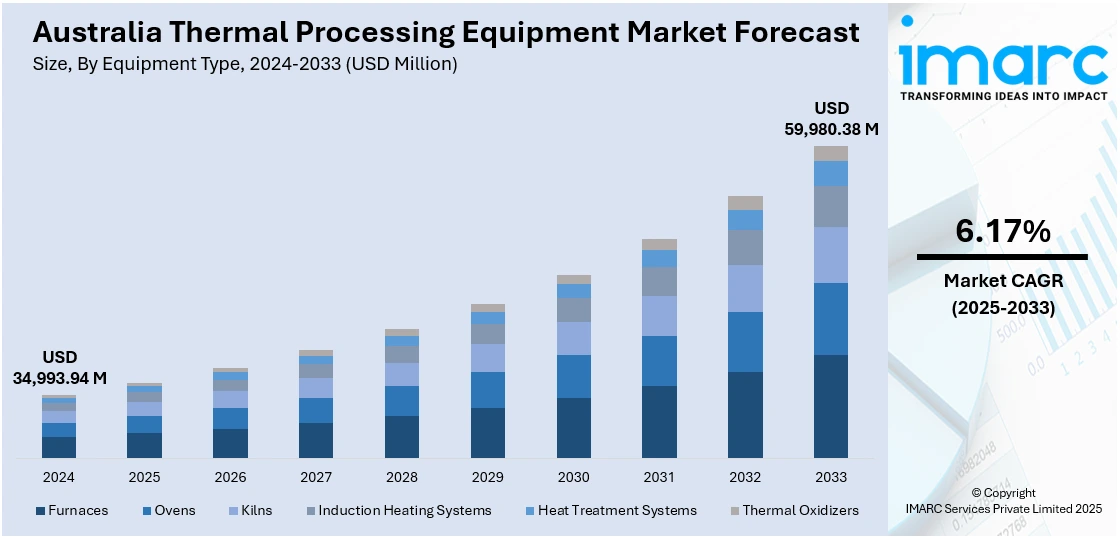

The Australia thermal processing equipment market size reached USD 34,993.94 Million in 2024. Looking forward, IMARC Group expects the market to reach USD 59,980.38 Million by 2033, exhibiting a growth rate (CAGR) of 6.17% during 2025-2033. The market is driven by rising demand for energy-efficient solutions, stringent environmental regulations, and the need for cost optimization. Additionally, the adoption of automation, IoT, and AI enhances operational efficiency and product quality. Growth in key industries such as food processing, mining, and chemicals is further expanding the Australia thermal processing equipment market share, while government sustainability initiatives encourage investments in advanced thermal technologies.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024 |

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 34,993.94 Million |

| Market Forecast in 2033 | USD 59,980.38 Million |

| Market Growth Rate 2025-2033 | 6.17% |

Australia Thermal Processing Equipment Market Trends:

Increasing Demand for Energy-Efficient Equipment

The market is witnessing a growing demand for energy-efficient solutions, driven by rising energy costs and stringent environmental regulations. During the fiscal year 2022–23, Australia's net energy use grew 2% to 23,294 PJ, with residential and industrial consumption growing 3% and 4%, respectively. At the same time, renewable sources grew by 12% to 325 PJ or 33% of the nation's electricity supply. Energy use from the transport sector jumped by 19% and agriculture by 12%, while manufacturing fell by 4%. With increasing energy intensity and demand in other sectors, the use of effective thermal processing equipment has become more prominent within the industrial setup of Australia. Industries such as food processing, mining, and chemicals are adopting advanced thermal systems that minimize energy consumption while maintaining high performance. Manufacturers are increasingly investing in technologies, including heat recovery systems, advanced insulation materials, and automated controls to optimize energy use. Additionally, government incentives for sustainable industrial practices are accelerating this shift. Companies that prioritize energy efficiency not only reduce operational costs but also enhance their compliance with Australia’s carbon emission targets. As sustainability becomes a key competitive differentiator, the market is expected to see continued innovation in energy-efficient thermal processing equipment, catering to both large-scale industries and small-to-medium enterprises seeking cost-effective and eco-friendly solutions.

To get more information on this market, Request Sample

Adoption of Automation and Smart Technologies in Thermal Processing

Automation and smart technologies are transforming the Australian thermal processing equipment market, improving precision, efficiency, and safety. In 2024, over 35% of Australian companies adopted AI and automation, and while larger companies enjoyed a 60% uptake rate, they invested a combined total of $3.5 billion in AI. Sectors of economic importance, such as the financial services industry and manufacturing, are applying automation in predictive analysis and improved process optimization, accelerated by $124 million in state-supported research and development funding. This trend foresees more intelligent, automated thermal processing machines to be in demand in Australia's industrial sector. Therefore, this is further propelling the Australia thermal processing equipment market growth. Industries are integrating IoT-enabled sensors, AI-based monitoring systems, and automated control mechanisms to enhance process accuracy and reduce human intervention. These advancements enable real-time data tracking, predictive maintenance, and remote operation, minimizing downtime and operational risks. The food and beverage sector, in particular, is leveraging smart thermal processing to ensure consistent product quality and compliance with safety standards. Furthermore, the mining and metals industry is adopting automated thermal systems to optimize high-temperature processes like smelting and heat treatment. As Industry 4.0 gains momentum, the demand for intelligent thermal processing equipment is expected to rise, with manufacturers focusing on scalable and interconnected solutions to meet changing industrial needs.

Australia Thermal Processing Equipment Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional levels for 2025-2033. Our report has categorized the market based on equipment type, process type, heating source, automation level, and end use industry.

Equipment Type Insights:

- Furnaces

- Ovens

- Kilns

- Induction Heating Systems

- Heat Treatment Systems

- Thermal Oxidizers

The report has provided a detailed breakup and analysis of the market based on the equipment type. This includes furnaces, ovens, kilns, induction heating systems, heat treatment systems, and thermal oxidizers.

Process Type Insights:

- Heat Treatment

- Annealing

- Hardening and Tempering

- Sintering

- Drying and Curing

- Calcination

A detailed breakup and analysis of the market based on the process type have also been provided in the report. This includes heat treatment, annealing, hardening and tempering, sintering, drying and curing, and calcination.

Heating Source Insights:

- Electric Thermal Processing

- Gas-Fired Systems

- Infrared and Microwave Heating

- Induction Heating

The report has provided a detailed breakup and analysis of the market based on the heating source. This includes electric thermal processing, gas-fired systems, infrared and microwave heating, and induction heating.

Automation Level Insights:

- Manual Thermal Processing Equipment

- Semi-Automated Systems

- Fully Automated Systems

A detailed breakup and analysis of the market based on the automation level have also been provided in the report. This includes manual thermal processing equipment, semi-automated systems, and fully automated systems.

End Use Industry Insights:

- Automotive

- Aerospace

- Metal and Mining

- Food and Beverage Processing

- Chemical and Petrochemical

- Electronics and Semiconductor

- Glass and Ceramics

- Energy and Power Generation

- Pharmaceuticals and Healthcare

The report has provided a detailed breakup and analysis of the market based on the end use industry. This includes automotive, aerospace, metal and mining, food and beverage processing, chemical and petrochemical, electronics and semiconductor, glass and ceramics, energy and power generation, and pharmaceuticals and healthcare.

Regional Insights:

- Australia Capital Territory & New South Wales

- Victoria & Tasmania

- Queensland

- Northern Territory & Southern Australia

- Western Australia

The report has also provided a comprehensive analysis of all the major regional markets, which include Australia Capital Territory & New South Wales, Victoria & Tasmania, Queensland, Northern Territory & Southern Australia, and Western Australia.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Australia Thermal Processing Equipment Market News:

- July 02, 2024: Global Heat Transfer launched its Thermal Fluid Analysis Kit and Light Ends Removal Kit (LERK) in Australia and New Zealand to enhance safety and efficiency in thermal processing systems. The LERK removes volatile compounds, providing flash point stability, and can be upgraded with remote monitoring to reduce fire risks and unplanned downtime. These products, which form part of GHT's Thermocare® program, are directed at industries including food, chemicals, and plastics where precise thermal fluid management is critical.

Australia Thermal Processing Equipment Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Equipment Types Covered | Furnaces, Ovens, Kilns, Induction Heating Systems, Heat Treatment Systems, Thermal Oxidizers |

| Process Types Covered | Heat Treatment, Annealing, Hardening and Tempering, Sintering, Drying and Curing, Calcination |

| Heating Sources Covered | Electric Thermal Processing, Gas-Fired Systems, Infrared and Microwave Heating, Induction Heating |

| Automation Levels Covered | Manual Thermal Processing Equipment, Semi-Automated Systems, Fully Automated Systems |

| End Use Industries Covered | Automotive, Aerospace, Metal and Mining, Food and Beverage Processing, Chemical and Petrochemical, Electronics and Semiconductor, Glass and Ceramics, Energy and Power Generation, Pharmaceuticals and Healthcare |

| Regions Covered | Australia Capital Territory & New South Wales, Victoria & Tasmania, Queensland, Northern Territory & Southern Australia, Western Australia |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Australia thermal processing equipment market performed so far and how will it perform in the coming years?

- What is the breakup of the Australia thermal processing equipment market on the basis of equipment type?

- What is the breakup of the Australia thermal processing equipment market on the basis of process type?

- What is the breakup of the Australia thermal processing equipment market on the basis of heating source?

- What is the breakup of the Australia thermal processing equipment market on the basis of automation level?

- What is the breakup of the Australia thermal processing equipment market on the basis of end use industry?

- What is the breakup of the Australia thermal processing equipment market on the basis of region?

- What are the various stages in the value chain of the Australia thermal processing equipment market?

- What are the key driving factors and challenges in the Australia thermal processing equipment market?

- What is the structure of the Australia thermal processing equipment market and who are the key players?

- What is the degree of competition in the Australia thermal processing equipment market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Australia thermal processing equipment market from 2019-2033.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Australia thermal processing equipment market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Australia thermal processing equipment industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)