India Pneumatic Conveying System Market Size, Share, Trends and Forecast by Operating Principle, Technology, End Use, and Region, 2025-2033

India Pneumatic Conveying System Market Size and Share:

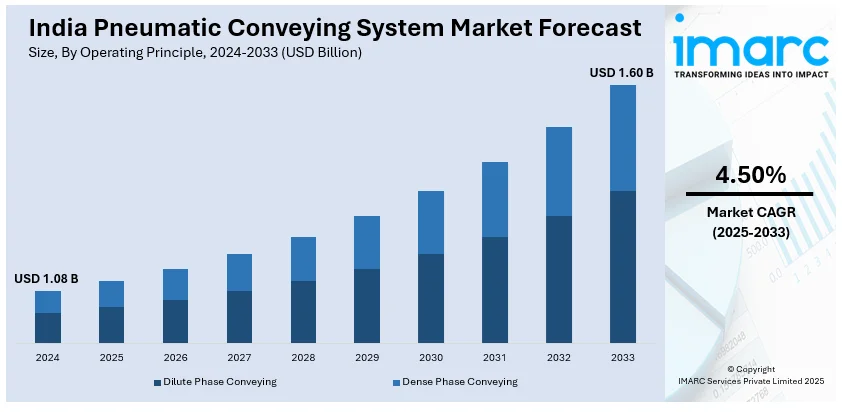

The India pneumatic conveying system market size reached USD 1.08 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 1.60 Billion by 2033, exhibiting a growth rate (CAGR) of 4.50% during 2025-2033. The market is led by increased manufacturing automation, increased food, cement, and pharmaceutical industries' demand, and requirements for material handling efficiently. Strict regulations concerning safety and pressure for dust-free and energy-saving systems are further propelling usage across all industry applications.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024

|

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 1.08 Billion |

| Market Forecast in 2033 | USD 1.60 Billion |

| Market Growth Rate (2025-2033) | 4.50% |

India Pneumatic Conveying System Market Trends:

Growing Demand for Dense Phase Conveying Systems

Dense phase conveying systems are becoming increasingly popular among Indian industries because they can convey fragile, abrasive, or heavy materials more effectively. Dense phase technology, unlike dilute phase systems, conveys materials at reduced velocities, which reduces product degradation, energy consumption, and system wear. This trend is most applicable in industries like food and beverages (F&B), chemicals, and cement, where material integrity and process reliability are key. With businesses concentrating increasingly on sustainable and energy-efficient operation, dense phase systems are increasing in popularity due to their potential to reduce emissions and optimize material flow. Furthermore, advances in control systems and flow measurement technology are also simplifying dense phase systems and facilitating them to become part of the production line.

To get more information on this market, Request Sample

Increasing Integration of Industry 4.0 and Intelligent Conveying Systems

The Indian market for pneumatic conveying systems is experiencing an upsurge in the adoption of Industry 4.0, with manufacturers incorporating intelligent sensors, real-time monitoring software, and automation programs to drive efficiency. One of the top FMCG players claimed a 20% drop in energy usage following the installation of Internet of Things (IoT)-equipped sensors in its pneumatic systems, illustrating the real payoff of digitalization. These smart systems offer real-time pressure and airflow monitoring, with optimized energy use and automatic shut-off of idling devices. IoT-enabled remote diagnostics and predictive maintenance provide least downtime and best material flow control and equipment well-being. IoT technologies are widely being used across industries like food processing, cement, and pharma to assist the move to smart factories and automated processes. This technological advancement is increasing productivity while lowering operational expenses considerably.

Emphasis on Hygienic and Contamination-Free Conveying Solutions

With growing regulatory pressure and consumer awareness around product safety and hygiene, there is an increasing shift toward pneumatic conveying systems that offer contamination-free and dust-tight material handling. Industries such as food, pharmaceuticals, and dairy are driving demand for hygienic conveying solutions made with stainless steel and equipped with easy-to-clean, closed-loop designs. These systems prevent cross-contamination, maintain product purity, and comply with stringent industry standards like GMP and FDA. Moreover, manufacturers are innovating with modular designs that enable faster system cleaning and maintenance, thereby reducing production downtime. This trend underscores the critical role of clean conveying technologies in ensuring product safety, improving workplace air quality, and supporting compliance with national and international health regulations.

India Pneumatic Conveying System Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the region level for 2025-2033. Our report has categorized the market based on operating principle, technology and end use.

Operating Principle Insights:

- Dilute Phase Conveying

- Dense Phase Conveying

The report has provided a detailed breakup and analysis of the market based on the operating principle. This includes dilute phase conveying, and dense phase conveying.

Technology Insights:

- Positive Pressure Systems

- Vacuum Systems

- Combination Systems

A detailed breakup and analysis of the market based on the technology have also been provided in the report. This includes positive pressure systems, vacuum systems, and combination systems.

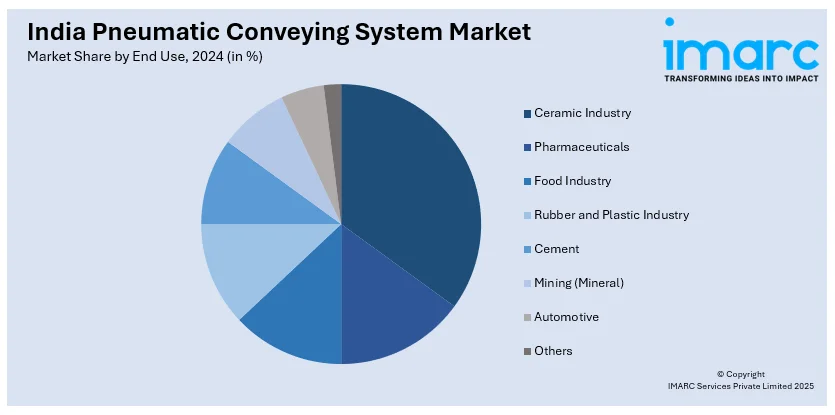

End Use Insights:

- Ceramic Industry

- Pharmaceuticals

- Food Industry

- Rubber and Plastic Industry

- Cement

- Mining (Mineral)

- Automotive

- Others

The report has provided a detailed breakup and analysis of the market based on the end use. This includes ceramic industry, pharmaceuticals, food industry, rubber and plastic industry, cement, mining (mineral), automotive, and others.

Regional Insights:

- North India

- South India

- East India

- West India

The report has also provided a comprehensive analysis of all the major regional markets, which include North, South, East, and West India.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

India Pneumatic Conveying System Market News:

- In June 2024, Kirloskar Pneumatic Company (KPCL) plans to acquire a 54.55% stake in Systems & Components India (S&C) for ₹15 crore in multiple tranches. The deal, aligned with KPCL’s refrigeration business, aims to expand operations into related segments. This strategic move is expected to boost KPCL’s market presence and business scale. The acquisition, subject to due diligence and adjustments, is anticipated to be completed within the next three months.

India Pneumatic Conveying System Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Billion USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Operating Principles Covered | Dilute Phase Conveying, Dense Phase Conveying |

| Technologies Covered | Positive Pressure Systems, Vacuum Systems, Combination Systems |

| End Uses Covered | Ceramic Industry, Pharmaceuticals, Food Industry, Rubber and Plastic Industry, Cement, Mining (Mineral), Automotive, Others |

| Regions Covered | North India, South India, East India, West India |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the India pneumatic conveying system market performed so far and how will it perform in the coming years?

- What is the breakup of the India pneumatic conveying system market on the basis of operating principle?

- What is the breakup of the India pneumatic conveying system market on the basis of technology?

- What is the breakup of the India pneumatic conveying system market on the basis of end use?

- What is the breakup of the India pneumatic conveying system market on the basis of region?

- What are the various stages in the value chain of the India pneumatic conveying system market?

- What are the key driving factors and challenges in the India pneumatic conveying system market?

- What is the structure of the India pneumatic conveying system market and who are the key players?

- What is the degree of competition in the India pneumatic conveying system market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the India pneumatic conveying system market from 2019-2033.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the India pneumatic conveying system market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the India pneumatic conveying system industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)