Baby Wipes Industry: Production and Cost Modelling Insights

What is Baby Wipes?

Baby wipes are wet disposable wipes used to clean the tender skin of an infant, mostly when changing diapers.

Key Applications Across Industries:

Composed of non-woven materials and embedded with delicate cleansing products, commonly made from water, mild surfactants, moisturizers such as aloe vera, and preservatives baby wipes are made to be delicate, hypoallergenic, and safe for daily use. Baby wipes provide an easy and sanitary option for parents and caregivers to keep infants clean without irritating them. Sold in a range of packaging sizes from canisters and travel packs to refill dispensers, baby wipes also find application outside of diapering to clean hands, faces, and surfaces, positioning them as an essential item in childcare and body hygiene.

What the Expert Says: Market Overview & Growth Drivers

The global baby wipes market reached USD 5.0 Billion in 2024. According to IMARC Group, the market is projected to reach USD 6.4 Billion by 2033, exhibiting a growth rate (CAGR) of 2.69% during 2025-2033. There are several driving forces for the global baby wipes market. First is the increasing sensitivity among parents towards baby hygiene and health, which underlines steady demand for effective and safe cleaning solutions.

Urbanization and dual-income households drive the demand for convenient, time-saving solutions such as baby wipes. Increased numbers of newborns, particularly in developing countries, add to the consumer market. Innovation is another key driver—more and more brands are introducing biodegradable, alcohol-free, and hypoallergenic versions to meet the needs of environmentally conscious and health-conscious consumers. The diversity of baby wipes formats (travel-size, refillable, canister) and distribution channels (pharmacies, supermarkets, and Internet) also increases accessibility and use. Additionally, intensive promotions and diversification of products by market leaders Procter & Gamble, Kimberly-Clark, and Johnson & Johnson have increased the reach of the market. Increased disposable income, enhanced standards of living, and the eagerness of parents to spend on high-end hygiene products also drive market growth.

Case Study on Cost Model of Baby Wipes Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a large-scale baby wipes manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed baby wipes manufacturing plant in Osaka, Japan. This plant is designed to produce 28,000 packs of baby wipes per day.

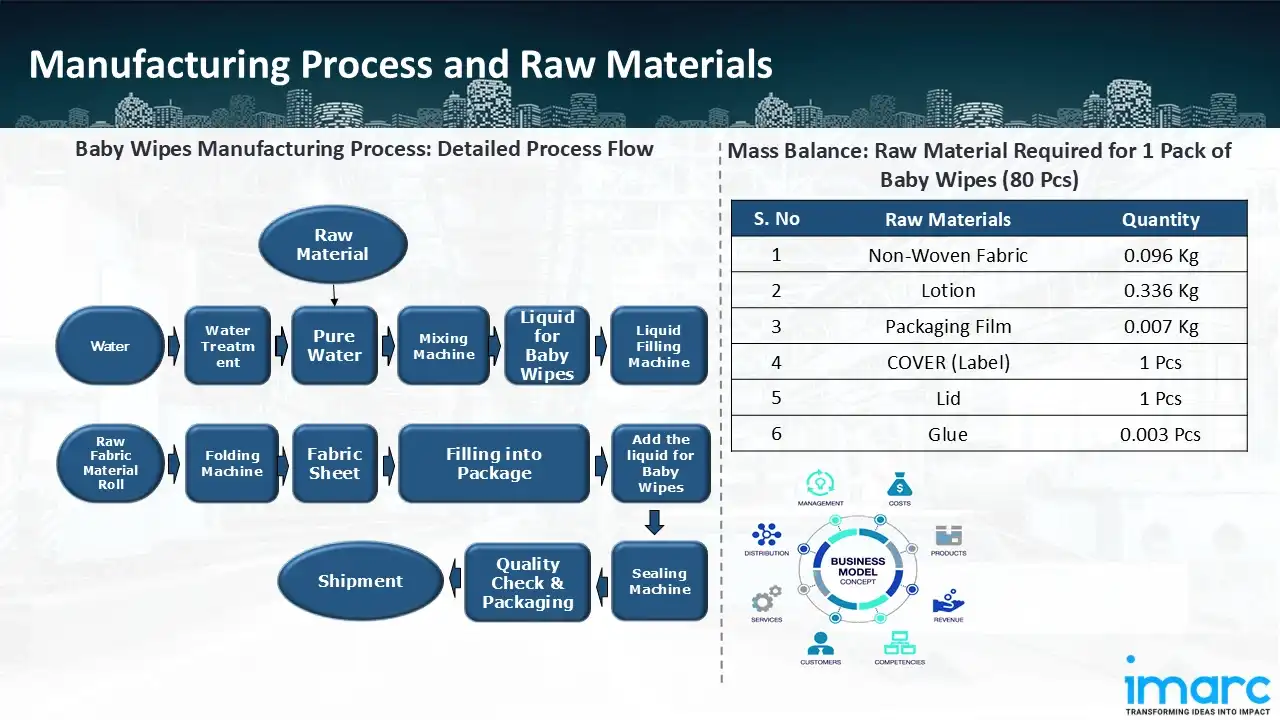

Manufacturing Process: The production of baby wipes is a multi-stage process to provide a hygienic, efficient, and easy-to-use product. It starts with formula preparation when ingredients like water, surfactants, moisturizers, and preservatives are blended together in large batch tanks to create a consistent cleansing solution. In addition, non-woven fabric, the raw material for wipes is manufactured through the wet-laid process (converting fiber slurry into sheets) or the dry-laid process (extruding plastic resins into fibers and adhering them into a sheet). The fabric is subsequently treated by passing through or spraying with the cleaning solution in a coating machine. The treated fabrics, rolled up into large master rolls, are next cut and slit into small consumer-sized sheets. The wipes are then packaged in airtight containers like pouches or plastic tubs, maintaining their moist state for use. Lastly, quality control measures are conducted at every stage of production to track parameters such as pH balance, viscosity, and microbial safety, to ensure the final product is not only safe but also effective for infant use. This efficient process allows high-volume, low-cost production with strict hygiene and safety controls in place.

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials used in the baby wipes manufacturing plant include non-woven fabric, lotion, packaging film, cover (label), lid and glue. For a plant producing 1 pack of baby wipes (80 pcs), 0.096 kg of non-woven fabric, 0.336 kg of lotion, 0.007 kg of packaging film, 1 pcs of cover (label), 1 pcs of lid and 0.003 pcs of glue is required.

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

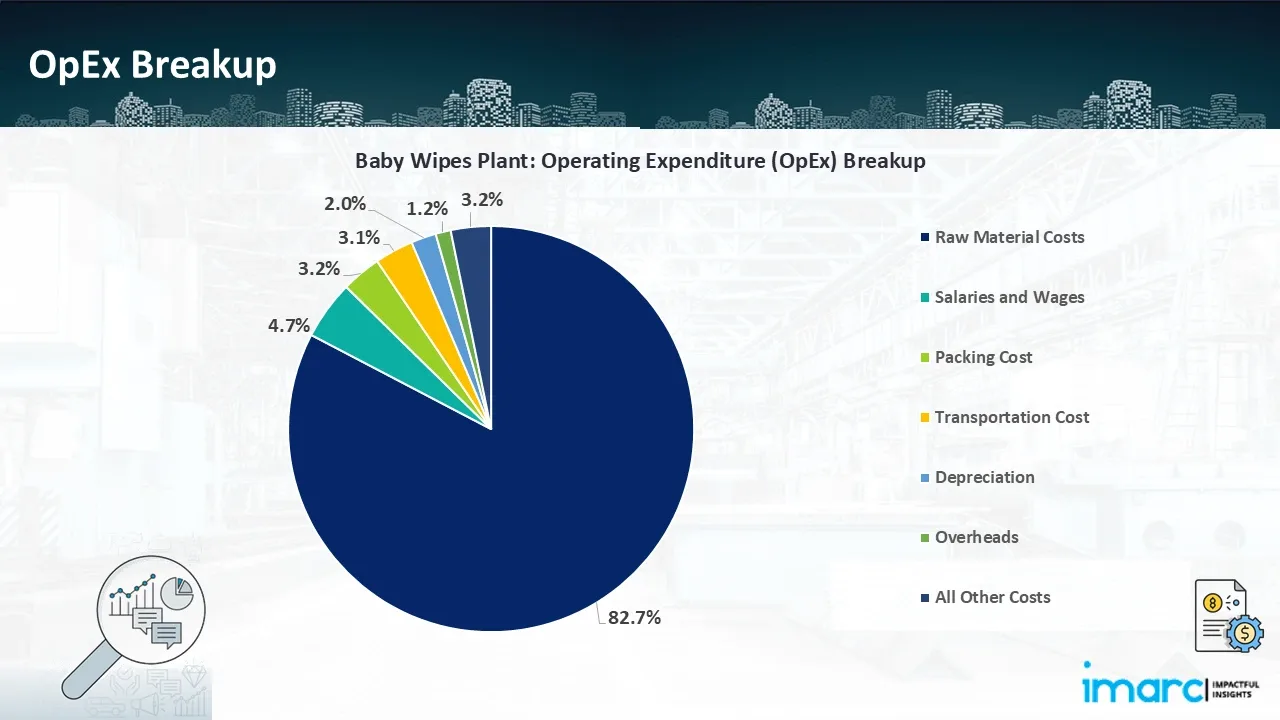

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

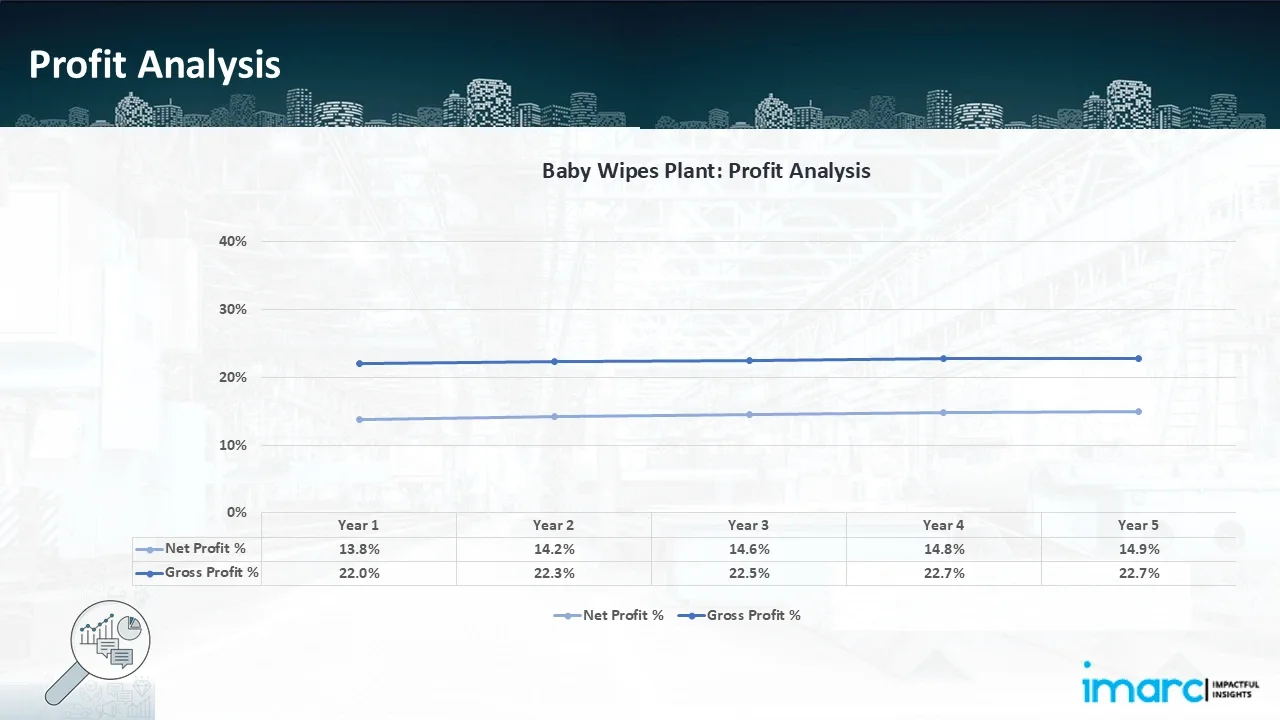

- Profitability Analysis Year on Year Basis: The proposed baby wipes plant, with a capacity of approximately 28,000 packs of baby wipes per day, achieved an impressive revenue of US$ 7.56 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins improve from 22.0% to 22.7% by year 5, and net profit rises from 13.8% to 14.9%, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the baby wipes manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of producing 28,000 packs of baby wipes per day, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights for strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In September 2024, GreenBaby introduced a range of hypoallergenic dry baby wipes made from natural fibres with the express purpose of serving customers with sensitive skin.

- In May 2024, First Quality announced that it will expand its newborn care business at its current Macon, Georgia, manufacturing facility for US$ 418 million. Nappies and training pants will have 50% more capacity thanks to the expansion, which will also generate 600 new employments.

- In April 2024, Kimberly-Clarke Corporation introduced fragrance-free personal wipes for sensitive skin.

- In March 2024, Proctor and Gamble expanded its biodegradable baby wipes line. In January 2025, it launched disinfecting wet wipes with dual-action cleaning.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104