Bagasse Based Biodegradable Cutlery Cost Model: Mapping Bagasse Cutlery Manufacturing Costs

What is Bagasse Based Biodegradable Cutlery?

Bagasse biodegradable cutlery is made from the fibrous material remaining after extracting sugarcane stalk juice, a low-value agricultural residue also known as bagasse.

Key Applications Across Industries:

The material is harvested from sugar mills, washed, pulped and mechanically molded into wet-molded forms; those wet parts are dried, pressed in heat-resistant molds and thermally cured to create rigid, food-grade spoons, forks and knives that are grease- and water-resistant but not covered with plastic coatings. In contrast to single-use plastics derived from petroleum or expanded polystyrene, bagasse cutlery is biodegradable and, when exposed to industrial composting conditions, degrades into CO2, water and biomass within weeks to a few months based on thickness and compost conditions. Production is relatively low-energy relative to some polymer pathways since it recycles a waste stream, and contemporary lines range from small modular presses for regional catering suppliers to high-speed automatic systems for large food-service orders. Finished products satisfy general food-safety and heat-resistance standards and are surface-treated to enhance oil repellency without compromising compostability. Since raw material supply is linked to sugarcane processing, industries tend to bunch up next to sugar mills, forming short, circular supply chains and minimizing transport emissions.

What the Expert Says: Market Overview & Growth Drivers

The global biodegradable cutlery market reached a value of USD 46.9 Million in 2024. According to IMARC Group, the market is projected to reach USD 69.3 Million by 2033, at a projected CAGR of 3.98% during 2025-2033. Globally, the market for bagasse biodegradable cutlery is being spurred by a convergence of regulatory, commercial and consumer forces.

Progressive bans and restrictions on single-use plastics in areas across Europe, North America, Asia and in many cities have driven near-term procurement needs from government institutions, festivals, airlines and food-service companies looking for compliant alternatives. Brands and corporates looking to address ESG goals and sustainable-packaging requirements are opting for compostables to reduce Scope 3 issues and signal sustainability to consumers. Increased consumer environmental consciousness, particularly among younger segments is driving purchasing choices towards transparent, sustainable packaging and cutlery, a boon for bagasse products that are viewed as "natural" and waste-saving. Economically, increased investments in automated molding and drying facilities have lowered unit costs, while large volumes of sugarcane cultivation in key agricultural areas ensures feedstock at volume; combined, these enhance price competitiveness compared to higher-cost bioplastics. Other tailwinds are increased online and takeaway food ordering (producing massive amounts of disposable cutlery), corporate purchasing policies supporting downstream compostable disposal, and increasing industrial composting and organic-waste infrastructure that render end-of-life claims believable. The production process of bagasse biodegradable cutlery includes a few principal steps, ranging from raw material preparation to molding and finishing for transforming sugarcane waste into strong, compostable cutlery.

Case Study on Cost Model of Bagasse Based Biodegradable Cutlery Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale bagasse based biodegradable cutlery manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed bagasse based biodegradable cutlery manufacturing plant in India. This plant is designed to manufacture 3,500 tons of bagasse based biodegradable cutlery annually.

Manufacturing Process: The manufacturing process of bagasse based biodegradable cutlery is initiated with bagasse gathering, where cellulosic sugarcane residue is collected from sugar mills following juice extraction. The raw material is then cleaned and pulped, eliminating unwanted substances like dirt, sugar residues, and lignin. The washed fibers are blended with water and, in some cases, with natural binding elements to create a pulp slurry of uniform viscosity. This pulp is then fed into precision molds made for any cutlery shapes like spoons, forks, and knives. The molding process is critical, in which the pulp is shaped under high pressure and heat in hydraulic presses or thermoformers. Heat not only forms the cutlery but also dries it out and adds rigidity, so the products are heat- and water-resistant without chemical finishes. Following molding, the cutlery is cured and dried in controlled ovens for dimensional stability and to avoid warping. Finished products are trimmed, polished, and quality-inspected for even thickness, durability, and smooth edges. Optional surface finishes, e.g., environmentally friendly coatings to improve oil and water resistance can be applied, as long as they retain compostability requirements. Last but not the least, the cutlery is sterilized, packaged, and labeled for distribution. Waste water recycling is frequently performed along the way, and refused items are re-pulped, ensuring minimal waste creation and encouraging a circular, low-carbon manufacturing process consistent with sustainable production practices.

Get a Tailored Feasibility Report for Your Project Request Sample

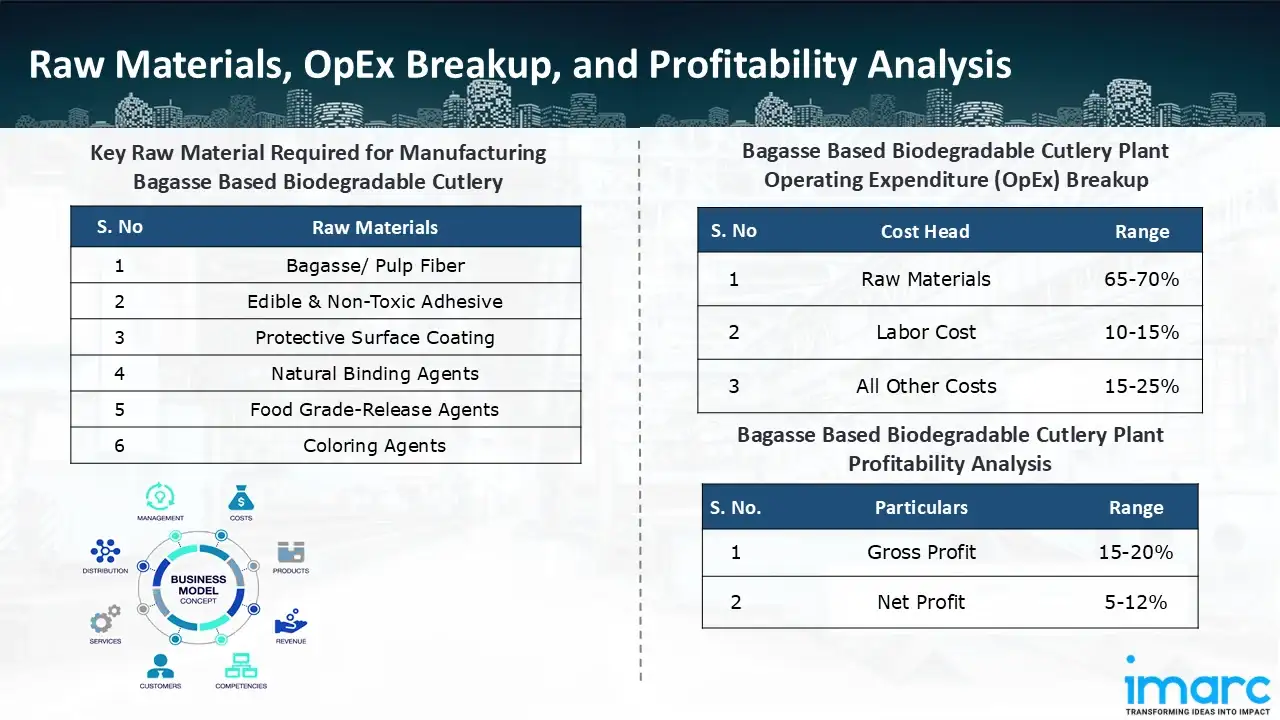

Raw Material Required:

The basic raw materials required for bagasse based biodegradable cutlery manufacturing include:

- Bagasse/ Pulp Fiber

- Edible & Non-Toxic Adhesive

- Protective Surface Coating

- Natural Binding Agents

- Food Grade-Release Agents

- Coloring Agents

Machineries Required:

- Bagasse Storage Silo

- Conveyor Belts

- Bagasse Washer / Pulper

- Refiner / Pulping Machine

- Screw Press / Belt Press

- Hydraulic Press / Compression Moulding

- Cooling Conveyor

- Hot-Air Chamber

- Tunnel Dryer / Hot-Air Oven / Rotary Dryer

- Trimming Machine / CNC Cutter

- Manual Finishing Table

- Visual Inspection Station

- Metal Detector

- Automatic Packaging Machine

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in a bagasse based biodegradable cutlery manufacturing plant ranges between 65-70%, labor cost ranges between 10% to 15%, and all other costs ranges between 15-25% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 15-20%, and net profit lie between the range of 5-12% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the bagasse based biodegradable cutlery manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 3,500 tons of bagasse based biodegradable cutlery annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In May 2025, leading third-party organisations have recognised several Dart Container products for their home compostability and recyclability as a result of the company's sustainability advancements. TÜV Austria, a reputable international standard for compostability, has certified all Dart-designed moulded fibre products as Home Compostable. The Association of Plastic Recyclers (APR) in the US also gave Dart's new clear microwaveable hinged containers, square plastic bowls, and clear polypropylene cups the Design® for Recyclability Recognition.

- In December 2024, Jiangsu Regreen New Material Technology Co., Ltd. formally opened its cutting-edge production facility for disposable biodegradable sugarcane pulp plates, marking a major step towards sustainability. The company's dedication to provide environmentally responsible substitutes for plastic and Styrofoam products has reached a significant turning point with the opening of the new factory.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics:

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104