Concrete Cost Model: Constructing the Path for Profits

What is Concrete?

Concrete is among the most widely used construction materials in the world due to its strength, versatility, and durability. It is a composite material largely made of cement, water, aggregates-sand, gravel, or crushed stone-and in some cases, admixtures which give special properties to the concrete. Cement is the binder that acts through hydration-a chemical reaction with water-to produce a hard matrix that binds the aggregates together.

Key Applications Across Industries:

This produces a very strong and durable material that is resistant to compressive loads, making it invaluable for infrastructures, buildings, bridges, pavements, and dams. The concrete formulation can be adjusted for specific structural and environmental needs, from high-strength concrete for skyscrapers to lightweight concretes for precast elements. In more recent years, these developments have resulted in specialized varieties: self-compacting concrete, fiber-reinforced concrete, high-performance concrete, and green concretes that use recycled materials or industrial by-products like fly ash and slag with sustainability in mind. Concrete is popular not only for its mechanical properties but also due to its relatively low cost and ability to use local materials. Additionally, because it is moldable into any shape that one desires before hardening, it allows for architectural creativity along with effective construction practices. And while its history is long, the study and innovation around concrete technology continue unabated, with current research aiming at reducing its carbon footprint, improving the durability when exposed to extreme conditions, and embedding smart materials for self-healing and enhanced structural monitoring, an ever-changing cornerstone in modern infrastructure.

What the Expert Says: Market Overview & Growth Drivers

The global concrete market reached a value of USD 1.85 Trillion in 2024. According to IMARC Group, the market is projected to reach USD 2.68 Trillion by 2033, at a projected CAGR of 4.0% during 2025-2033. The main factors driving the demand for concrete in the global market include rapid urbanization, infrastructure development, and population increase. The growth of cities and industrial areas in emerging economies, particularly in the construction of housing, commercial buildings, transportation systems, and public structures, is reliant on concrete as a basic input material.

The government's interest in modernizing its highways, airports, rail systems, and alternative fueling facilities has also sustained demand for concrete globally. This development, along with industrialization in the methods of construction, has popularized the adoption of prefabricated and ready-mix concrete systems that ensure higher quality, better speed, and less waste at actual construction sites. Another major driver is the growing emphasis on sustainability and eco-friendly building materials. The concrete industry is witnessing innovation in low-carbon cement alternatives, utilization of recycled aggregates, and carbon capture technologies in cement kilns due to environmental concerns. These developments have made concrete more compatible with global climate goals without sacrificing structural advantages. Such expansions of smart cities and green buildings further facilitate advanced types, such as self-healing and high-performance concretes, which eventually grant better durability and lower maintenance costs. Increasingly, investments in infrastructure resilience-especially within areas prone to natural disasters-are driving the adoption of reinforced and fiber-enhanced concretes for improved performance under stress. Technological advances in additive manufacturing, also known as 3D concrete printing, further diversify its uses into housing and modular construction. All these factors together point to concrete's continuous importance as a strategic material underpinning global economic and infrastructural growth.

Case Study on Cost Model of Concrete Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale concrete manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed concrete manufacturing plant in India. This plant is designed to manufacture 35 cubic meter of concrete per hour.

Manufacturing Process: The manufacturing of concrete is a very carefully controlled process that is designed to produce a material that is consistently uniform in quality, strength, and workability. This process starts with the selection and proportioning of raw materials: cement, fine and coarse aggregates, water, and, when necessary, chemical or mineral admixtures. The properties of the raw materials have a major influence on the performance characteristics of the final concrete product. The cement acts as the binder; the aggregates are used for bulk and strength, while the water starts the hydration action that causes the mixture to set. First, the materials are measured and batched to a predetermined mix design that, in turn, is based on the application, strength required, and conditions of exposure. After batching, the ingredients are mechanically mixed in a concrete mixer to produce a uniform blend. Mixing can be done in a central batching plant for ready-mix concrete or can be done at the construction site itself. Good mixing is essential to assure a uniform distribution of cement paste around the aggregates without segregation or bleeding. After mixing, the fresh concrete is rapidly transported to the place of casting by transit mixers, pumps, or conveyors in order not to set prematurely. Upon arrival, the concrete is deposited and compacted into molds, formwork, or structural frameworks to eliminate air voids and attain maximum density; compaction is usually achieved by the use of mechanical vibrators. After placement, concrete is kept moist for several days in a process called curing, which is essential to allow complete hydration of cement. It enhances strength, durability, and resistance to cracking. In this regard, the hardened concrete is inspected and tested for compressive strength to ensure that it complies with the design specifications before the structural application of the material.

Get a Tailored Feasibility Report for Your Project Request Sample

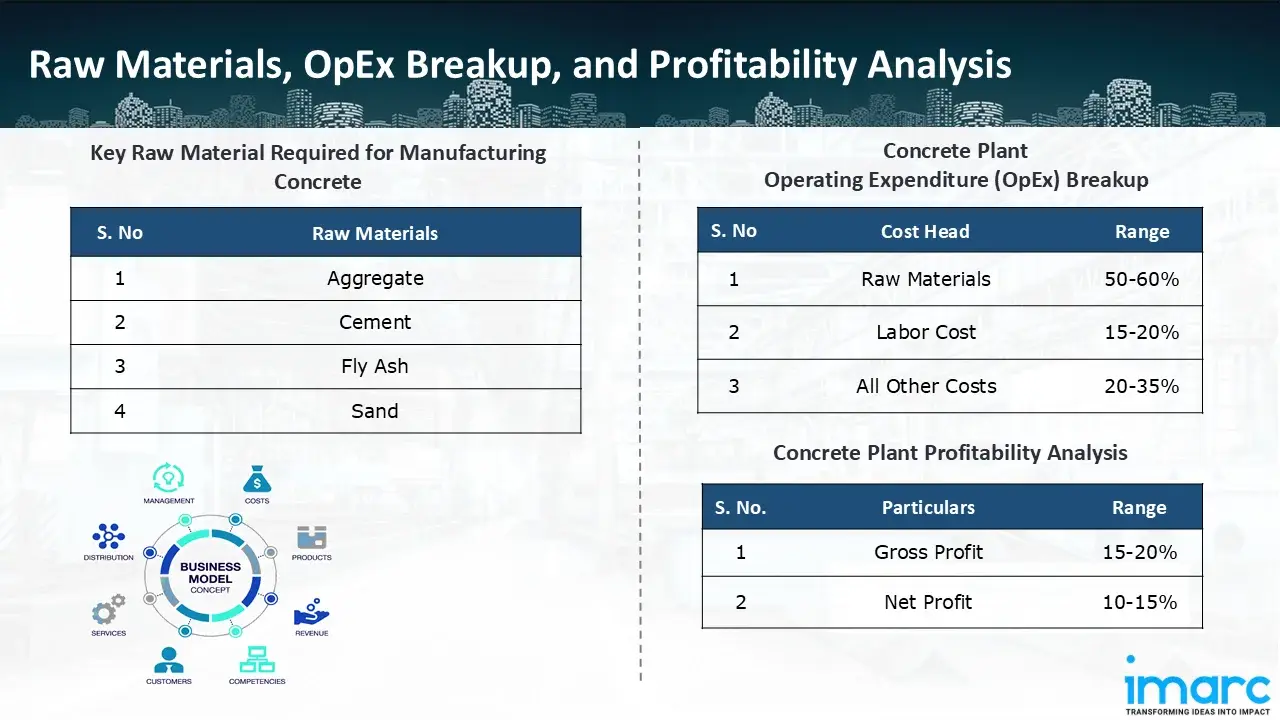

Raw Material Required:

The basic raw materials required for concrete manufacturing include:

- Aggregate

- Cement

- Fly Ash

- Sand

Machineries Required:

- Aggregate Bins

- Conveyors

- Weighing Hoppers

- Cement Silos

- Admixture Tanks

- Water Tank

- Water Metering System

- Concrete Mixer (Twin-Shaft Mixer/ Pan Mixer/ Drum Mixer)

- Plc (Programmable Logic Controller) Unit

- Control Panel

- Discharge Chute

- Transit Mixers

- Dust Collectors

- Water Sprays

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in a concrete manufacturing plant ranges between 50-60%, labor cost ranges between 15% to 20%, and all other costs ranges between 20-35% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 15-20%, and net profit lie between the range of 10-15% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the concrete manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 35 cubic meter of concrete per hour, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In October 2025, Haymaker Acquisition Corp. 4, a publicly traded special purpose acquisition company, and Concrete Partners Holding, LLC, a ready-mix concrete logistics and distribution platform strategically situated in Oklahoma and Arkansas, announced that Suncrete has acquired nearly all of the assets of SRM, Inc. DBA Schwarz Ready Mix and SRM Leasing, LLC, as well as all of the issued and outstanding equity interests of Schwarz Sand, LLC. Together, these companies operate a ready-mix concrete business in Oklahoma City and the surrounding areas.

- In February 2025, Concrete Supply Co., LLC announced the purchase of Argos' ready-mix assets. Concrete Supply Co., LLC is a top producer of ready-mix concrete for residential, commercial, and DOT projects. With this calculated move, Concrete Supply Co.'s operations will grow from 90 to 120 locations, greatly increasing its ability to service clients in important growth cities throughout the Carolinas, such as Raleigh, Charlotte, Charleston, and Columbia.

- In March 2024, BMC Enterprises Inc., a prominent regional ready-mixed concrete, aggregates and building goods company in the US, has been acquired by BREEDON Group plc for an enterprise value of US$300 million (£238.1 million).

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104