Optimizing Calcium Hypochlorite Production: A Comprehensive Cost Analysis

What is Calcium Hypochlorite?

Calcium hypochlorite is a powerful chemical compound, widely used in many different applications and industries.

Key Applications Across Industries:

This white solid, made up of calcium, oxygen, and chlorine, contains excellent chlorine content with a strong oxidation capability. Being an oxidizing agent that gives out chlorine when dissolved in water, it is in huge demand for the treatment, sanitation, and disinfection of water.

What the Expert Says: Market Overview & Growth Drivers

As per an IMARC report, the volume of the GCC calcium hypochlorite market reached 10,014 Tons in 2024, with a CAGR of 1.9% from 2019 to 2024. In the coming years, the market is anticipated to expand at a CAGR of around 1.7% between 2025 and 2033, aiming for an estimated volume of 11,815 Tons by 2033. This chemical substance is utilized for water purification, disinfection, and sanitation reasons, and has been experiencing notable market influences and trends.

The growing requirement for clean water across various industrial applications, ranging from municipal water treatment to swimming pools and food processing, is a major contributor. Increasing cases of water-borne diseases that necessitate more effective disinfection are bringing an upward trend in demand for calcium hypochlorite. One of the other significant factors that are increasingly gained traction is the use of calcium hypochlorite sanitizer in healthcare facilities, hospitality, and residential sectors post COVID-19 period, due to growing focus on public health and hygiene. In addition, the expanding pool and spa sector, especially in developing regions, is also contributing to the growth of the calcium hypochlorite market.

Case Study on Cost Model of Calcium Hypochlorite Manufacturing Plant:

Objective

One of our clients has approached us to conduct a feasibility study for establishing a mid to large-scale calcium hypochlorite manufacturing plant in Kuwait.

IMARC Approach: Comprehensive Financial Feasibility

We have developed a comprehensive financial model for the plant's setup and operations. The proposed facility is designed with a production capacity of 50.0 tons per day of calcium hypochlorite.

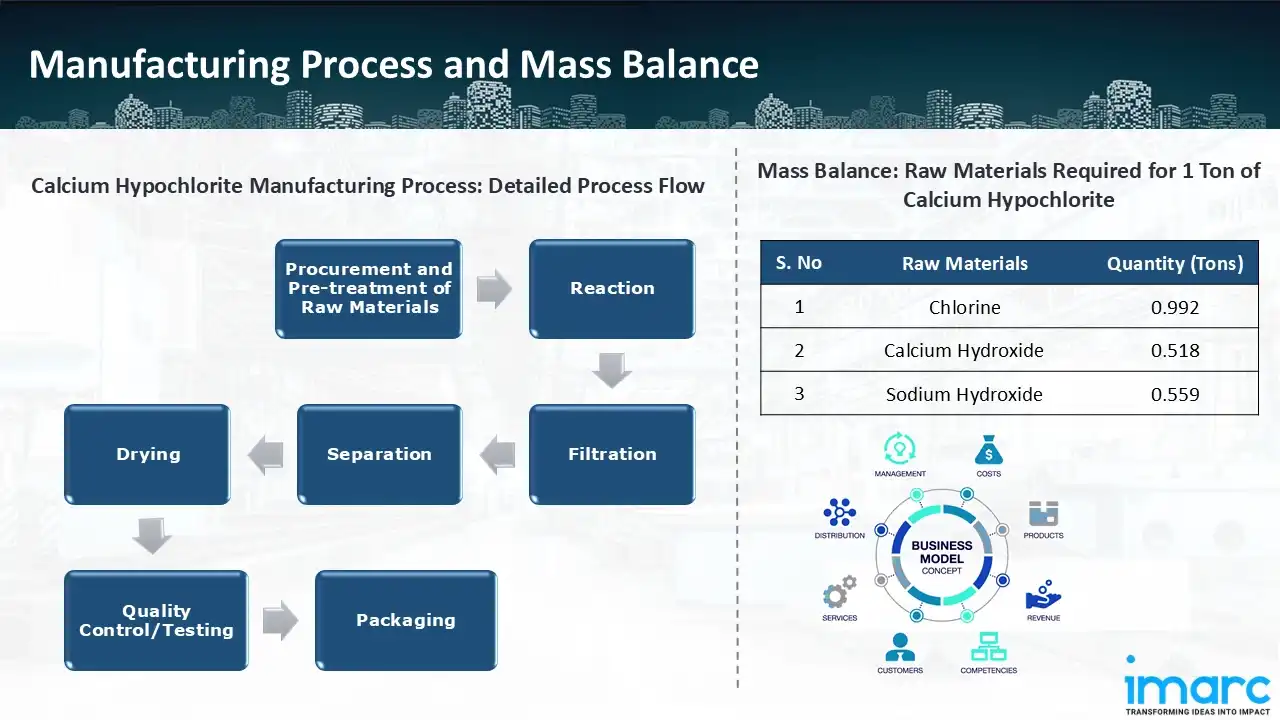

Manufacturing Process: Several significant steps are required in the process of manufacturing calcium hypochlorite to achieve a quality product. Purchase and pre-treatment of raw materials such as slaked lime and chlorine gas that meet purification standards is the first step. These raw materials, after pre-treatment, remove contaminants that would otherwise interfere with the reaction. The reaction step primarily gives the main product of calcium hypochlorite, along with byproducts like calcium chloride, which are produced when chlorine gas is added to slaked lime at a specific temperature and pressure. The mixture obtained is filtered to remove impurities in solid form and to make the liquid uniform. The separation and drying stage produce a dry and stable product by removing excess moisture from the filtered material using drying devices, including rotary or fluidized bed dryers. Finally, the produced calcium hypochlorite is tested through quality control, and the parameters observed include moisture content, particle size, and accessible chlorine concentration, all of which must meet the standards of the industry. Once the product has passed through, it is packaged in moisture-resistant bags in order to maintain stability and quality during storage and transport. For example, the time taken in the case of applications like water treatment and sanitation delivers a reliable and effective final product.

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials utilized in the calcium hypochlorite manufacturing plant include slaked lime, chlorine, and caustic soda. For a plant producing approximately 1 ton of calcium hypochlorite, the raw material requirements are as follows: chlorine (0.992 tons), calcium hydroxide (0.518 tons), and sodium hydroxide (0.559 tons).

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

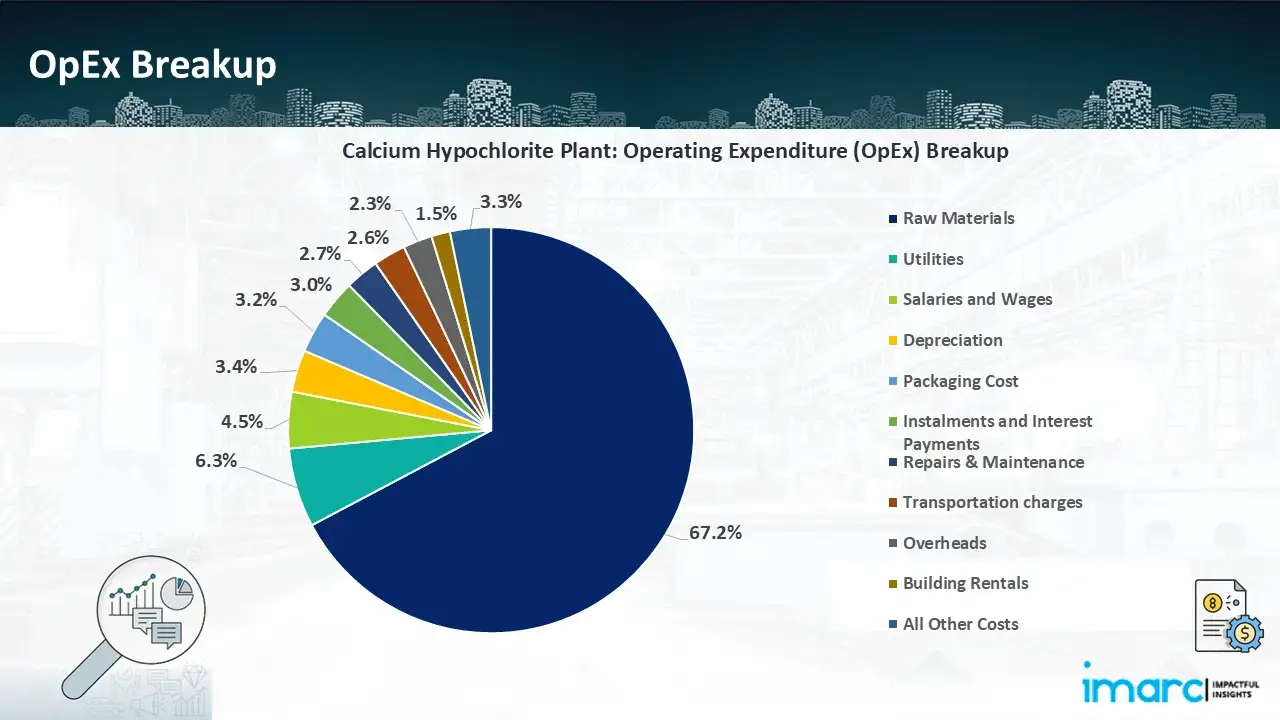

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

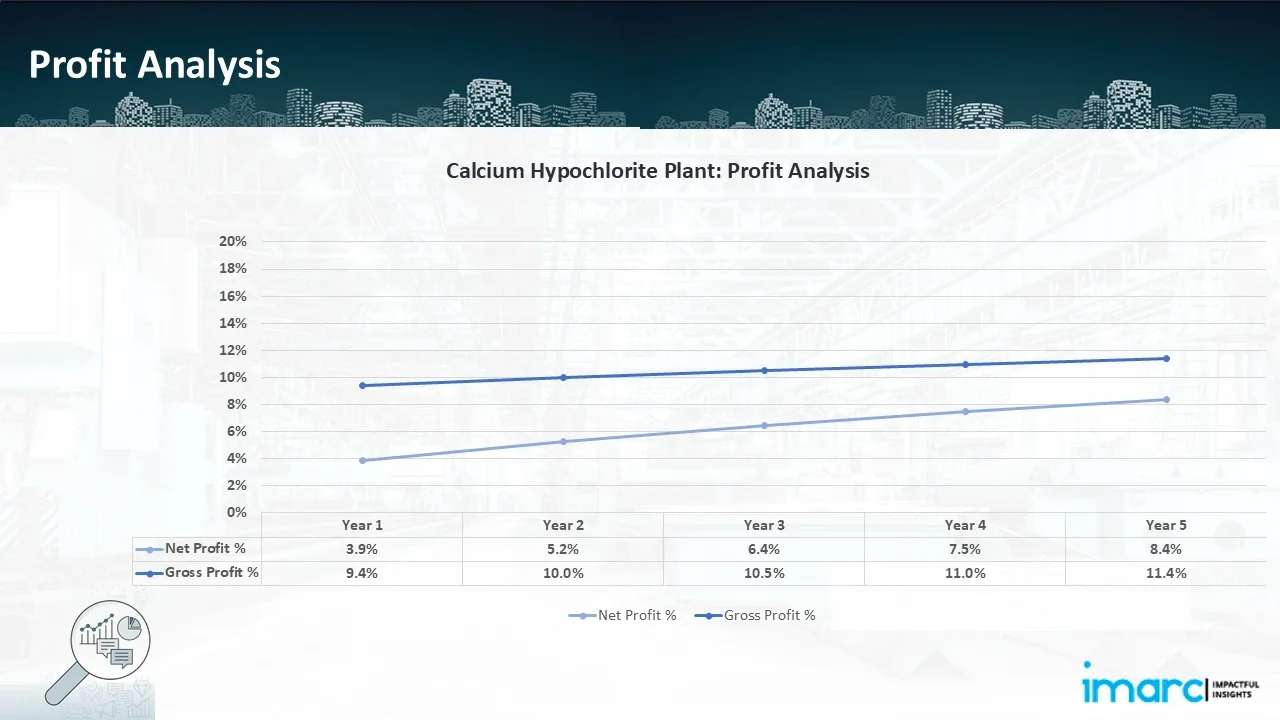

- Profitability Analysis Year on Year Basis: The proposed calcium hypochlorite plant, with a capacity of 50.0 tons per day, achieved an impressive revenue of US$ 17.21 million in its first year. We assisted our client in developing a detailed cost rising throughout the years. Gross profit margin improved from 9.4% to 11.4% throughout the years, and net profit went up from 3.9% to 8.4%, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

We carefully crafted our financial model for the calcium hypochlorite production facility to align with the client’s goals. It offers a comprehensive examination of production expenses, covering raw materials, manufacturing methods, capital investments, and operational costs. Designed to meet the distinct need for generating 50.0 tons of calcium hypochlorite daily, the model emphasizes primary cost factors and predicts profitability, considering market trends, inflation, and possible variations in raw material costs. This detailed financial model provides the client with essential insights for informed decision-making, showcasing our dedication to providing accurate, client-oriented solutions that guarantee the enduring success of large manufacturing projects.

Latest News and Developments:

- In September 2024, Primo Chemicals announced that the company was able to open its Stable Bleaching Powder facility with the capacity of 33,000 TPA.

- In February 2020, Gujarat Alkalies and Chemicals has started producing stable bleaching powder (SBP) on a commercial basis at Dahej. The plant's 15,000 TPA capacity reflects a calculated decision to satisfy SBP's growing demand.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Brief List of Our Services: Market Entry and Expansion

- Market Entry and Opportunity Assessment

- Competitive Intelligence and Benchmarking

- Procurement Research

- Pricing and Cost Research

- Sourcing

- Distribution Partner Identification

- Contract Manufacturer Identification

- Regulatory Approvals, and Licensing

- Factory Setup

- Factory Auditing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory set-up services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104