Japan Ball Bearing Market Expected to Reach USD 4.9 Billion by 2033 - IMARC Group

Japan Ball Bearing Market Statistics, Outlook and Regional Analysis 2025-2033

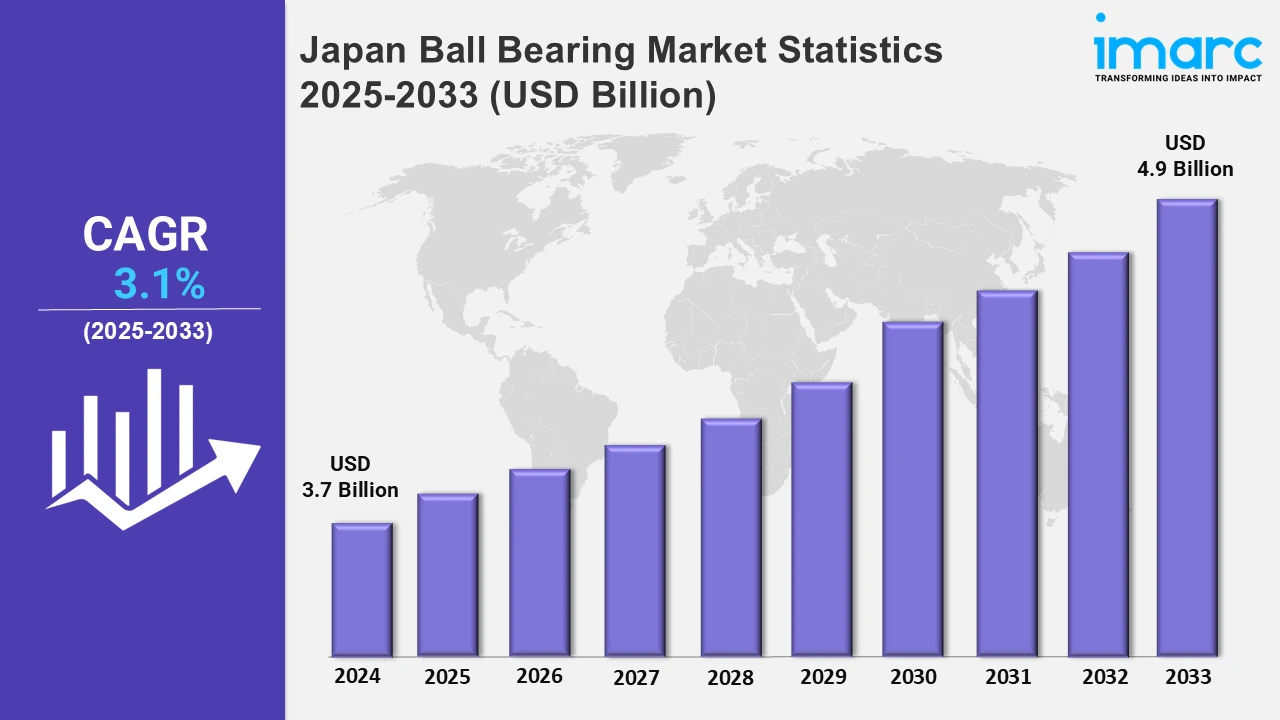

The Japan ball bearing market size was valued at USD 3.7 Billion in 2024, and it is expected to reach USD 4.9 Billion by 2033, exhibiting a growth rate (CAGR) of 3.1% from 2025 to 2033.

To get more information on this market, Request Sample

The market for ball bearing in Japan is largely driven by the elevating demand from the automotive sector that focuses highly on improving fuel efficiency and reducing friction in mechanical systems. Besides this, the industry is expanding due to the extensive usage of precision bearing in the automation and robotics sectors. The rising renewable energy project demands, particularly wind turbines, are boosting the need for high-performance bearings. For example, renewable energy projects saw a 10% increase in capacity installations in 2024. In line with this, the ongoing industrial machinery upgrades that entail smooth operations and energy efficiency are also catalyzing the market in Japan. For instance, in April 2024, JTEKT Corporation unveiled its latest advancements in bearing technology, focusing mainly on enhanced environmental performance and energy efficiency.

Additionally, the inflating investment in research and development activities by key manufacturers is also encouraging innovation in the ball bearing market. Moreover, the rising trend of utilizing intelligent bearings integrated with IoT sensors for monitoring temperature, vibration, and rotational speed in real-time is bolstering the market growth. For instance, Kashima Bearings Inc., based in Japan, produces miniature and small-sized ball bearings that are important for miniaturization, information equipment, and weight reduction. Apart from this, the growing need for predictive maintenance solutions that minimize downtime and costs incurred for repairs is increasing the adoption of this product across several industries, such as automotive and manufacturing.

Japan Ball Bearing Market Statistics, By Region

The market research report has also provided a comprehensive analysis of all the major regional markets, which include the Kanto region, Kinki region, Central/ Chubu region, Kyushu-Okinawa region, Tohoku region, Chugoku region, Hokkaido region, and Shikoku region. The rising precision bearing adoption in robotics and automation industries is catalyzing the ball bearing market in Japan.

Kanto Region Ball Bearing Market Trends:

The Kanto region is a significant consumer of ball bearings on account of its strong industrial base. Tokyo and Yokohama hubs are the primary manufacturing centers for machinery and automobile sectors. Besides this, proximity to major port facilities is supporting the market.

Kinki Region Ball Bearing Market Trends:

The Kinki region of Japan houses the leading companies in bearing technology, which is the source of demand for high-performance ball bearings. The area’s extensive network of manufacturers drives the need for automation and precision. Apart from this, diversified industrial areas are escalating the market. For example, SKF offers ready-to-mount units for moderate loads.

Central/Chubu Region Ball Bearing Market Trends:

Nagoya, in the Central/Chubu region of Japan, is a major automotive and aerospace manufacturing hub. Its focus on accurate engineering and cutting-edge technology boosts the demand for specialized bearings. Moreover, companies, including Nippon Seiko (NSK), are considered as one of the major producers of ball bearings.

Kyushu-Okinawa Region Ball Bearing Market Trends:

The increasing emphasis of the Kyushu-Okinawa region on advanced manufacturing and heavy industries is positively influencing the market in Japan. Also, the popularity of electronics and automotive production, especially in Fukuoka and Kitakyushu, propels the requirement for ball bearings.

Tohoku Region Ball Bearing Market Trends:

The Tohoku region’s technological advancements and industrial output focused on the automobile and renewable energy sectors support the need for high-performance bearings across various industries. Additionally, the elevating wind-power generation is anticipated to augment the market in the coming years.

Chugoku Ball Bearing Market Trends:

The Chugoku region plays an important role in Japan’s ball bearing market as it concentrates largely on manufacturing and energy industries. Moreover, this area requires specialized bearings that assure smooth operations with less wear on large machinery. Apart from this, the rising need for ensuring long-term industry sustainability is expanding the market in Chugoku.

Hokkaido Region Ball Bearing Market Trends:

The Hokkaido region’s emphasis on reserve extraction and agriculture, which are industries that demand specific bearings for efficient functioning of the equipment, is also a contributor to the market growth. Key players in this area emphasize on equipment reliability under extreme conditions, thereby elevating the market.

Shikoku Region Ball Bearing Market Trends:

The manufacturing facilities in the Shikoku region, mainly in Kagawa and Ehime, have bolstered the demand for precision ball bearings for machine tools and textile sectors. Apart from this, extensive product variant applications are bolstering the overall market.

Top Companies Leading in the Japan Ball Bearing Industry

There are several companies in the Japan ball bearing market. Leading players are investing heavily in sustainability efforts, with enterprises like NTN Corporation employing renewable energy sources in production methods. Moreover, the company in October 2024 launched a Power Purchase Agreement to annually minimize CO₂ emissions by 589 tons. Apart from this, the Nachi-Fujikoshi bearings business uses superior materials.

Japan Ball Bearing Market Segmentation Coverage

- Based on the application, the market has been segmented into automobile, general engineering, mining and construction, railways, aerospace and shipping, agriculture, and others. The automobile industry is important in ensuring smooth rotation in transmissions, engines, and wheels of vehicles. General engineering is necessary for the precise movement of machinery under heavy loads at extreme speeds. The mining and construction sectors depend on conveyors, crushers, and excavators. Ball bearings are used in railways, aerospace, and shipping industries to offer smooth motion and minimize friction. In agriculture, these tools are put in farming equipment, including valves, pumps, and irrigation systems.

| Report Features | Details |

|---|---|

| Market Size in 2024 | USD 3.7 Billion |

| Market Forecast in 2033 | USD 4.9 Billion |

| Market Growth Rate 2025-2033 | 3.1% |

| Units | Billion USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Applications Covered | Automobile, General Engineering, Mining and Construction, Railways, Aerospace and Shipping, Agriculture, Others |

| Regions Covered | Kanto Region, Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Browse IMARC Related Reports on Ball Bearing Market:

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Inquire Before Buying

Inquire Before Buying

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

.webp)

.webp)