Japan Furfural Market Size, Share, Trends and Forecast by Process, Raw Material, Application, End User, and Region, 2026-2034

Japan Furfural Market Overview:

The Japan furfural market size reached USD 51.4 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 85.6 Million by 2034, exhibiting a growth rate (CAGR) of 5.83% during 2026-2034. The increasing product demand in the pharmaceutical, agriculture, and automotive sectors, shift towards bio-based chemicals, evolving sustainability trends, the growing need for eco-friendly solvents, and advancements in furfural production technology are some of the major factors positively impacting Japan furfural market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025 |

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 51.4 Million |

| Market Forecast in 2034 | USD 85.6 Million |

| Market Growth Rate (2026-2034) | 5.83% |

Japan Furfural Market Trends:

Augmenting Demand for Furfural and Furfuryl Alcohol from Diverse Sectors

The expanding use of furfuryl alcohol, a key derivative of furfural, results in an increased demand of the product, which is providing an impetus to Japan furfural market. Furfuryl alcohol is widely used in the manufacturing of resins, which are crucial for industries such as automotive, construction, and manufacturing. As one of the largest automotive markets in the world, Japan's automobile manufacturing industry contributes significantly to its economic wealth, making up 13.9 percent of manufacturing GDP and 2.9 percent of total GDP. The growth of the automotive sector leads to the increased demand for these resins, as they are valued for their durability, heat resistance, and chemical stability, which make them suitable for various industrial applications, including the production of molded parts, coatings, and adhesives. The pharmaceutical and chemical sectors also contribute to the requirement, as furfural is utilized in the synthesis of several compounds and intermediates. The reliance of Japan on furfural as a feedstock is expected to increase with the growing innovative applications of this chemical product in various industries.

Shift Towards Bio-based and Sustainable Production

The increasing shift towards bio-based and sustainable production methods is positively influencing the Japan furfural market outlook. Japan aims to reduce its carbon footprint by achieving net-zero emissions by 2050 and a 46% reduction in greenhouse gas emissions by 2030. With the growing emphasis on environmental sustainability, Japan's furfural producers are focusing on reducing their carbon footprint and improving the eco-friendliness of their manufacturing processes. In the traditional method, furfural is produced through the dehydration of pentose sugars extracted from plant materials such as corn cobs, sugarcane, and wood. Biotechnological advancements are at the forefront, which enables manufacturers to rely on renewable raw materials and minimize environmental effects related to furfural production. The new approaches involving energy-saving processes and waste recycling are also gaining popularity. This shift aligns with broader environmental goals in Japan, where industries are under increasing pressure to adopt greener practices. Moreover, as the demand for eco-friendly products rises, companies that emphasize sustainability in their operations are likely to gain a competitive advantage, contributing to the long-term Japan furfural market growth.

Japan Furfural Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country level for 2026-2034. Our report has categorized the market based on process, raw material, application, and end user.

Process Insights:

- Quaker Batch Process

- Chinese Batch Process

- Rosenlew Continuous Process

- Others

The report has provided a detailed breakup and analysis of the market based on the process. This includes quaker batch process, Chinese batch process, rosenlew continuous process, and others.

Raw Material Insights:

- Corn Cobs

- Rice Husk

- Sugarcane Bagasse

- Others

A detailed breakup and analysis of the market based on the raw material have also been provided in the report. This includes corn cobs, rice husk, sugarcane bagasse, and others.

Application Insights:

- Furfuryl Alcohol

- Solvent

- Others

The report has provided a detailed breakup and analysis of the market based on the application. This includes furfuryl alcohol, solvent, and others.

End User Insights:

- Agriculture

- Petroleum Refineries

- Paints and Coatings

- Pharmaceuticals

- Others

A detailed breakup and analysis of the market based on the end user have also been provided in the report. This includes agriculture, petroleum refineries, paintings and coatings, pharmaceuticals, and others.

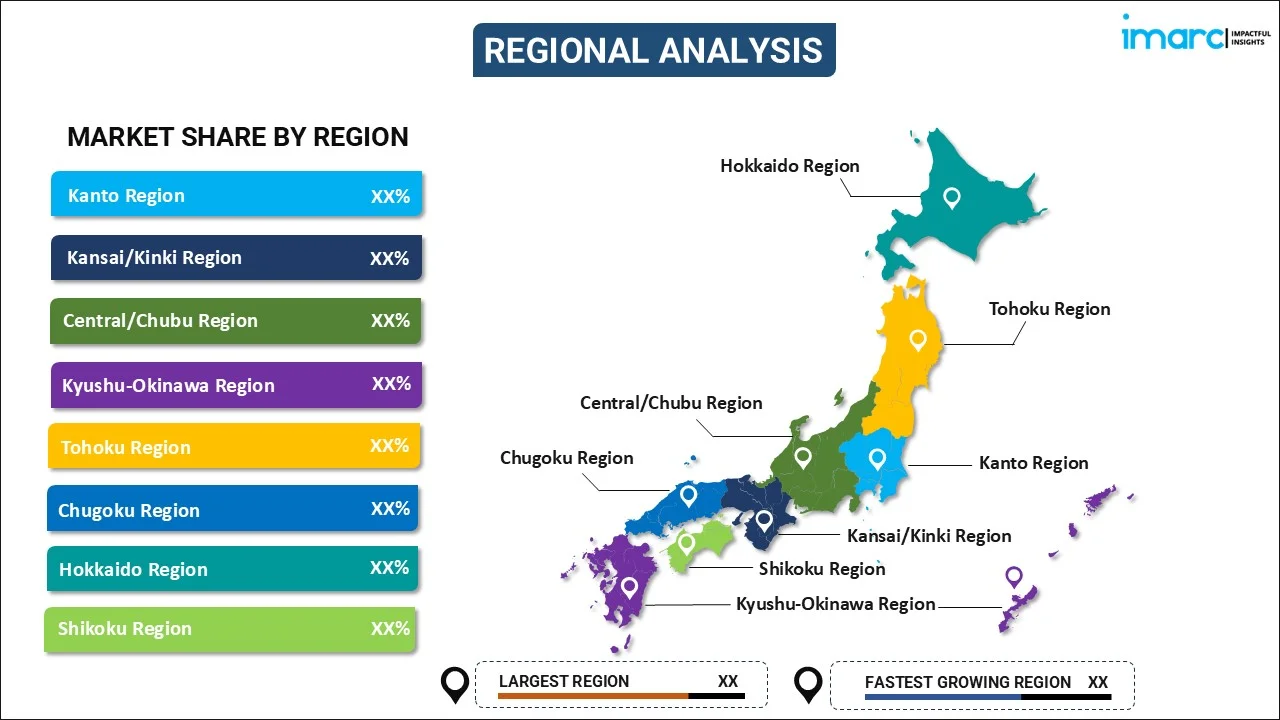

Regional Insights:

- Kanto Region

- Kansai/Kinki Region

- Central/ Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Kanto region, Kansai/Kinki region, Central/Chubu region, Kyushu-Okinawa region, Tohoku region, Chugoku region, Hokkaido region, and Shikoku region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Japan Furfural Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Processes Covered | Quaker Batch Process, Chinese Batch Process, Rosenlew Continuous Process, Others |

| Raw Materials Covered | Corn Cobs, Rice Husk, Sugarcane Bagasse, Others |

| Applications Covered | Furfuryl Alcohol, Solvent, Others |

| End Users Covered | Agriculture, Petroleum Refineries, Paintings and Coatings, Pharmaceuticals, Others. |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan furfural market performed so far and how will it perform in the coming years?

- What is the breakup of the Japan furfural market on the basis of process?

- What is the breakup of the Japan furfural market on the basis of raw material?

- What is the breakup of the Japan furfural market on the basis of application?

- What is the breakup of the Japan furfural market on the basis of end user?

- What is the breakup of the Japan furfural market on the basis of region?

- What are the various stages in the value chain of the Japan furfural market?

- What are the key driving factors and challenges in the Japan furfural market?

- What is the structure of the Japan furfural market and who are the key players?

- What is the degree of competition in the Japan furfural market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan furfural market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan furfural market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan furfural industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)