Japan Industrial Conveyor Systems Market Size, Share, Trends and Forecast by Type, Load Capacity, Operation Type, End Use Industry, and Region, 2026-2034

Japan Industrial Conveyor Systems Market Overview:

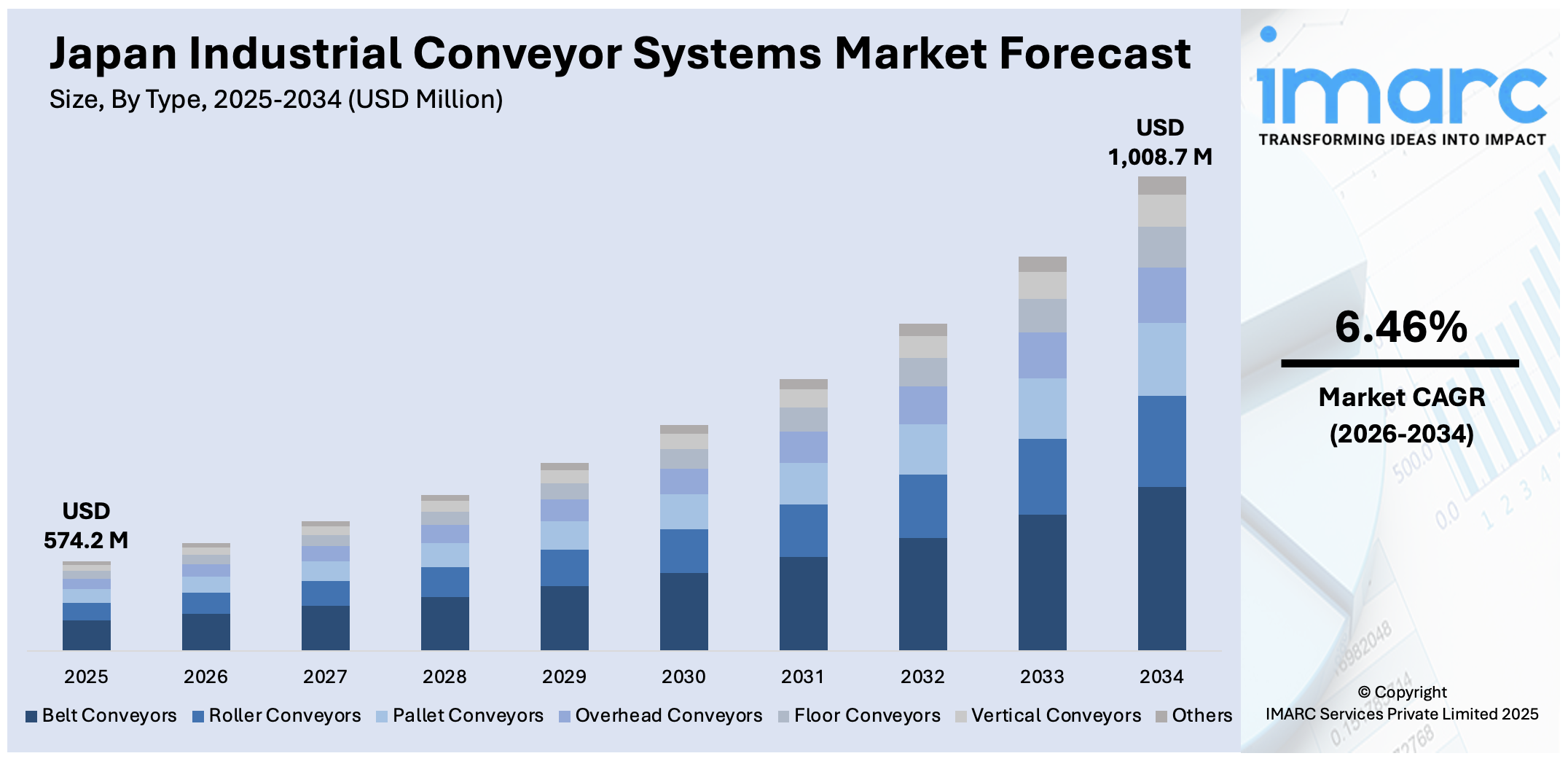

The Japan industrial conveyor systems market size reached USD 574.2 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 1,008.7 Million by 2034, exhibiting a growth rate (CAGR) of 6.46% during 2026-2034. The market is influenced by growing automation in production, need for efficient manufacturing processes, and demand for lower labor costs. The intensifying emphasis on sustainability, energy efficiency, and the evolution of advanced technologies, such as Internet of Things (IoT) and artificial intelligence (AI) is driving the market growth. In addition, smart and flexible conveyor solutions are widely being adopted across industries to enhance productivity, decrease downtime, and provide improved control over operations, further adding impetus to the Japan industrial conveyor systems market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025

|

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

|

Market Size in 2025

|

USD 574.2 Million |

|

Market Forecast in 2034

|

USD 1,008.7 Million |

| Market Growth Rate 2026-2034 | 6.46% |

Japan Industrial Conveyor Systems Market Trends:

Automation and Industry 4.0 Integration

Automation in Japan is reshaping the industrial conveyor systems market with the help of Industry 4.0 technologies, such as the IoT, AI, and machine learning (ML). The smart conveyor systems support real-time monitoring, predictive maintenance, and higher efficiency through adjustments to dynamic production requirements. AI and ML algorithms process huge amounts of data to recognize potential system breakdowns before they happen, reducing downtime and enhancing productivity in general. Manufacturing sectors like automotive and electronics are at the forefront of embracing these smart technologies to automate processes, lower labor expenses, and improve precision. Through the implementation of these intelligent technologies, manufacturers can realize more adaptable, responsive production lines, as well as improve overall operational efficiency and minimize expensive errors.

To get more information on this market Request Sample

Development of the "Autoflow Road" Freight System

Japan is about to transform its freight transport with the "Autoflow Road." The system, which is a long-distance automated conveyor belt system running parallel to existing roads, will deliver the cargo over large distances without human drivers. It is designed to solve acute labor shortages in logistics while minimizing environmental footprint. The system will deliver 25, 000 truck driver equivalent daily freight and run 24/7 with fully automated loading and unloading functions. By linking major transportation hubs between cities such as Tokyo and Osaka, the Autoflow Road will accelerate logistics, enhance delivery efficiency, and reduce traffic congestion. The project is consistent with Japan's overall strategy of combining automation and sustainability within its infrastructure in keeping with the nation's targets to decrease dependence on conventional trucking as well as increase the overall efficiency of its transportation infrastructure.

Focus on Energy Efficiency and Sustainability

Efficiency and sustainability are becoming key concerns in Japan's conveyor systems market, prompted by increasing environmental pressure. Suppliers are emphasizing saving on energy consumption and carbon emissions by using energy-saving motors, regenerative braking solutions, and eco-friendly components within their designs. As per the sources, in June 2024, Japan unveiled a 310-mile autonomous conveyor belt project designed to replace 25,000 trucks, transporting cargo between Tokyo and Osaka, with completion expected by 2034. Furthermore, these developments support maximizing energy consumption, minimizing operation costs, and reducing the overall environmental footprint. Modular conveyor systems are also becoming popular because they are flexible and scalable, allowing companies to quickly adjust to shifting production requirements without significant infrastructure adjustments. This trend not only helps companies save costs but also complements Japan's overall sustainability objectives, as the nation increasingly incorporates green technologies into industrial processes to achieve environmental goals thus strengthening the Japan industrial conveyor systems market growth.

Japan Industrial Conveyor Systems Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional levels for 2026-2034. Our report has categorized the market based on type, load capacity, operation type, and end use industry.

Type Insights:

- Belt Conveyors

- Roller Conveyors

- Pallet Conveyors

- Overhead Conveyors

- Floor Conveyors

- Vertical Conveyors

- Others

The report has provided a detailed breakup and analysis of the market based on the type. This includes belt conveyors, roller conveyors, pallet conveyors, overhead conveyors, floor conveyors, vertical conveyors, and others.

Load Capacity Insights:

- Light-Duty Conveyors

- Medium-Duty Conveyors

- Heavy-Duty Conveyors

A detailed breakup and analysis of the market based on the load capacity have also been provided in the report. This includes light-duty conveyors, medium-duty conveyors, and heavy-duty conveyors.

Operation Type Insights:

- Automated Conveyors

- Semi-Automated Conveyors

- Manual Conveyors

The report has provided a detailed breakup and analysis of the market based on the operation type. This includes automated conveyors, semi-automated conveyors, and manual conveyors.

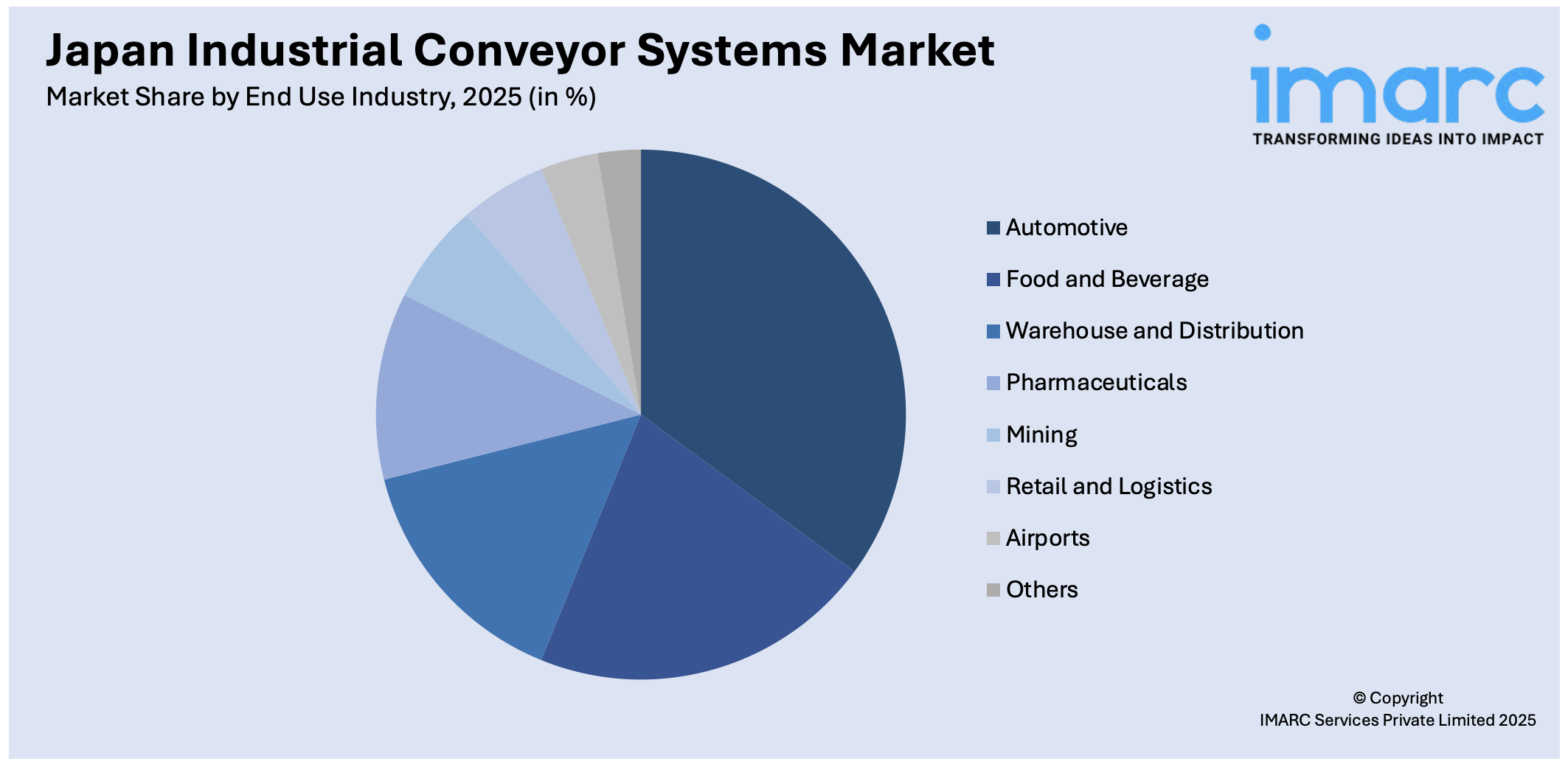

End Use Industry Insights:

Access the comprehensive market breakdown Request Sample

- Automotive

- Food and Beverage

- Warehouse and Distribution

- Pharmaceuticals

- Mining

- Retail and Logistics

- Airports

- Others

A detailed breakup and analysis of the market based on the end use industry have also been provided in the report. This includes automotive, food and beverage, warehouse and distribution, pharmaceuticals, mining, retail and logistics, airports, and others.

Regional Insights:

- Kanto Region

- Kansai/Kinki Region

- Central/ Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Kanto, Kansai/Kinki, Central/ Chubu, Kyushu-Okinawa, Tohoku, Chugoku, Hokkaido, and Shikoku Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Japan Industrial Conveyor Systems Market News:

- In June 2024, GenNx360 Capital Partners revealed that its portfolio firm, Pacteon Group, has acquired Descon Integrated Conveyor Solutions, a top conveyor system provider to the food and beverage market. The acquisition solidifies Pacteon's leadership in end-of-line packaging automation and increases its capabilities. CEO Mike Odom was looking forward to enhancing customer solutions, while GenNx360 Managing Partner Monty Yort pointed out the growth potential generated by the acquisition.

Japan Industrial Conveyor Systems Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Types Covered | Belt Conveyors, Roller Conveyors, Pallet Conveyors, Overhead Conveyors, Floor Conveyors, Vertical Conveyors, Others |

| Load Capacities Covered | Light-Duty Conveyors, Medium-Duty Conveyors, Heavy-Duty Conveyors |

| Operation Types Covered | Automated Conveyors, Semi-Automated Conveyors, Manual Conveyors |

| End Use Industries Covered | Automotive, Food and Beverage, Warehouse and Distribution, Pharmaceuticals, Mining, Retail and Logistics, Airports, Others |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan industrial conveyor systems market performed so far and how will it perform in the coming years?

- What is the breakup of the Japan industrial conveyor systems market on the basis of type?

- What is the breakup of the Japan industrial conveyor systems market on the basis of load capacity?

- What is the breakup of the Japan industrial conveyor systems market on the basis of operation type?

- What is the breakup of the Japan industrial conveyor systems market on the basis of end use industry?

- What is the breakup of the Japan industrial conveyor systems market on the basis of region?

- What are the various stages in the value chain of the Japan industrial conveyor systems market?

- What are the key driving factors and challenges in the Japan industrial conveyor systems market?

- What is the structure of the Japan industrial conveyor systems market and who are the key players?

- What is the degree of competition in the Japan industrial conveyor systems market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan industrial conveyor systems market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan industrial conveyor systems market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan industrial conveyor systems industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)