Japan Lubrication Systems Market Size, Share, Trends and Forecast by Type, Application, Process, and Region, 2026-2034

Japan Lubrication Systems Market Overview:

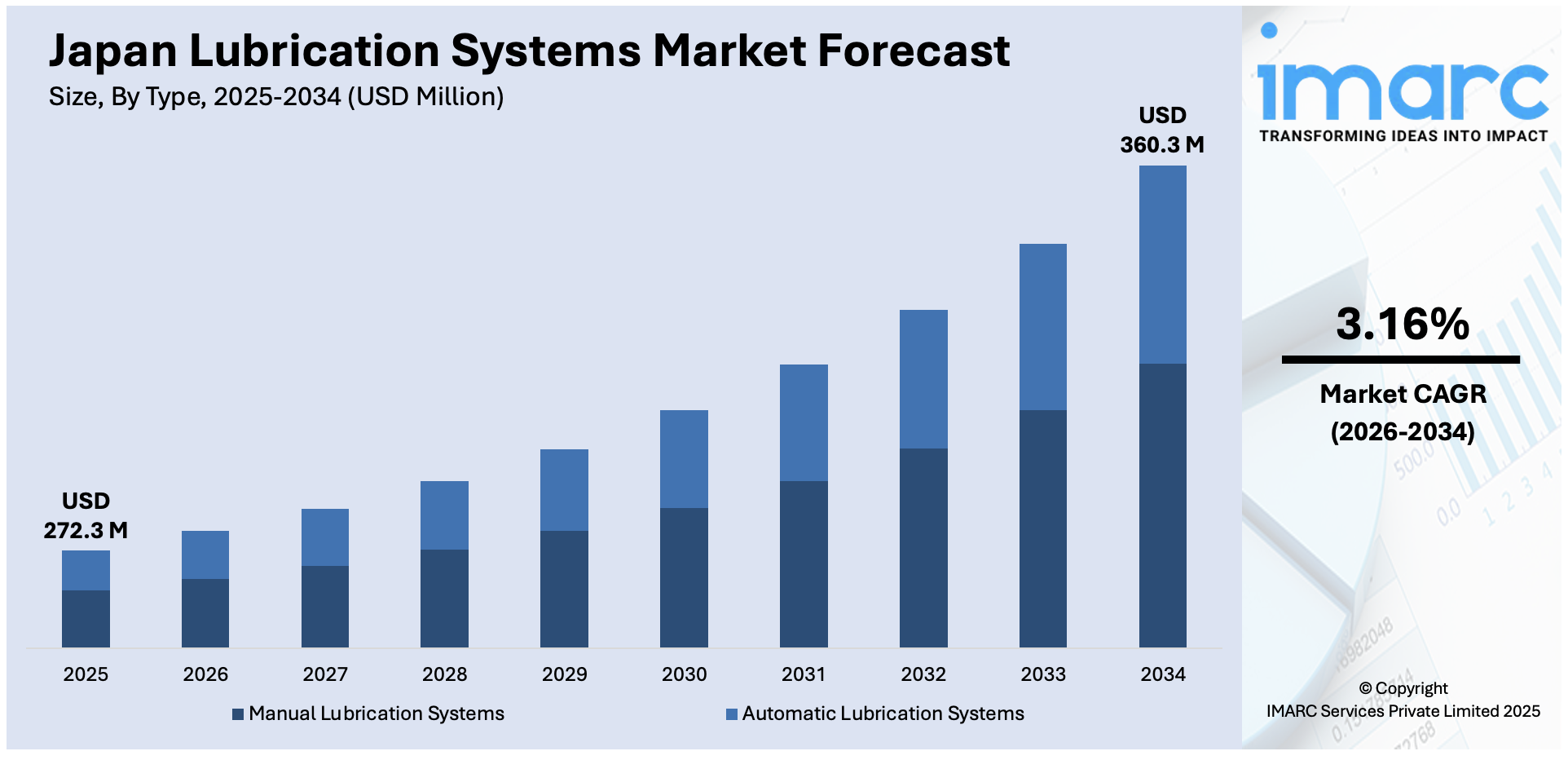

The Japan lubrication systems market size reached USD 272.3 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 360.3 Million by 2034, exhibiting a growth rate (CAGR) of 3.16% during 2026-2034. The market is driven by the country's advanced manufacturing sector, high automation standards, and emphasis on precision engineering. Industries such as automotive, robotics, and electronics heavily rely on efficient lubrication solutions to enhance performance and reduce maintenance downtime. Growing sustainability efforts and technological innovations further support the Japan lubrication systems market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025 |

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 272.3 Million |

| Market Forecast in 2034 | USD 360.3 Million |

| Market Growth Rate 2026-2034 | 3.16% |

Japan Lubrication Systems Market Trends:

Advanced Manufacturing and Industrial Automation

Japan’s position as a global leader in advanced manufacturing and industrial automation is a major driver of its lubrication systems market. The country’s automotive, electronics, and precision machinery sectors require highly efficient, reliable, and automated lubrication solutions to ensure continuous operation and reduce wear on critical components. The adoption of robotics combined with high-speed machinery in production systems drives the necessity to implement centralized and automated lubrication systems. These systems bring productivity improvements together with reduced maintenance expenses and enhanced precision performance, which match the requirements of Japanese high-output industries. The focus on operational efficiency, combined with uptime requirements by manufacturers, drives stable market demand for state-of-the-art lubrication systems that meet Japan's industrial and technological standards.

To get more information on this market Request Sample

Emphasis on Machinery Longevity and Efficiency

Japanese industries place significant emphasis on extending machinery lifespan and optimizing operational efficiency, which boosts demand for effective lubrication systems. Regular and precise lubrication is critical for reducing friction, wear, and energy consumption in mechanical components. In sectors such as automotive and aerospace, where equipment reliability is paramount, lubrication systems help maintain performance while minimizing unplanned downtime and costly repairs. This focus on preventive maintenance aligns with Japan’s broader culture of meticulous quality control and production efficiency. Additionally, companies are increasingly adopting predictive maintenance strategies, further integrating lubrication systems with monitoring technologies to optimize equipment health, ultimately supporting the Japan lubrication systems market growth.

Environmental Regulations and Sustainability Goals

Japan’s strong environmental regulations and commitment to sustainable industrial practices are pushing companies to adopt eco-friendly and energy-efficient lubrication systems. These systems help reduce oil waste, prevent leaks, and lower overall consumption of lubricants. As the country targets lower carbon emissions and greater resource efficiency, industries are under pressure to implement greener technologies. Lubrication systems that support biodegradable or low-toxicity lubricants, along with equipment that ensures minimal lubricant use, are gaining traction. This trend is especially important in sectors operating near environmentally sensitive areas. Government incentives and strict compliance standards are encouraging widespread adoption of sustainable lubrication practices, further propelling market growth. For instance, in May 2024, Eneos said that it had completed a demonstration project in which it generated refined base oil as part of a government-commissioned study on recycled waste lubricants in Japan. Tests conducted by third parties verified that gasoline engine oils that comprise their re-refined base oil pass the Sequence IIIH test, an international standard for high-temperature oxidation resistance.

Japan Lubrication Systems Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional levels for 2026-2034. Our report has categorized the market based on type, application, and process.

Type Insights:

- Manual Lubrication Systems

- Automatic Lubrication Systems

- Single-line Lubrication Systems

- Dual-line Lubrication Systems

- Multi-line Lubrication Systems

- Series Progressive

- Circulating Oil

- Oil and Air

The report has provided a detailed breakup and analysis of the market based on the type. This includes manual lubrication systems and automatic lubrication systems (single-line lubrication systems, dual-line lubrication systems, multi-line lubrication systems, series progressive, circulating oil, and oil and air).

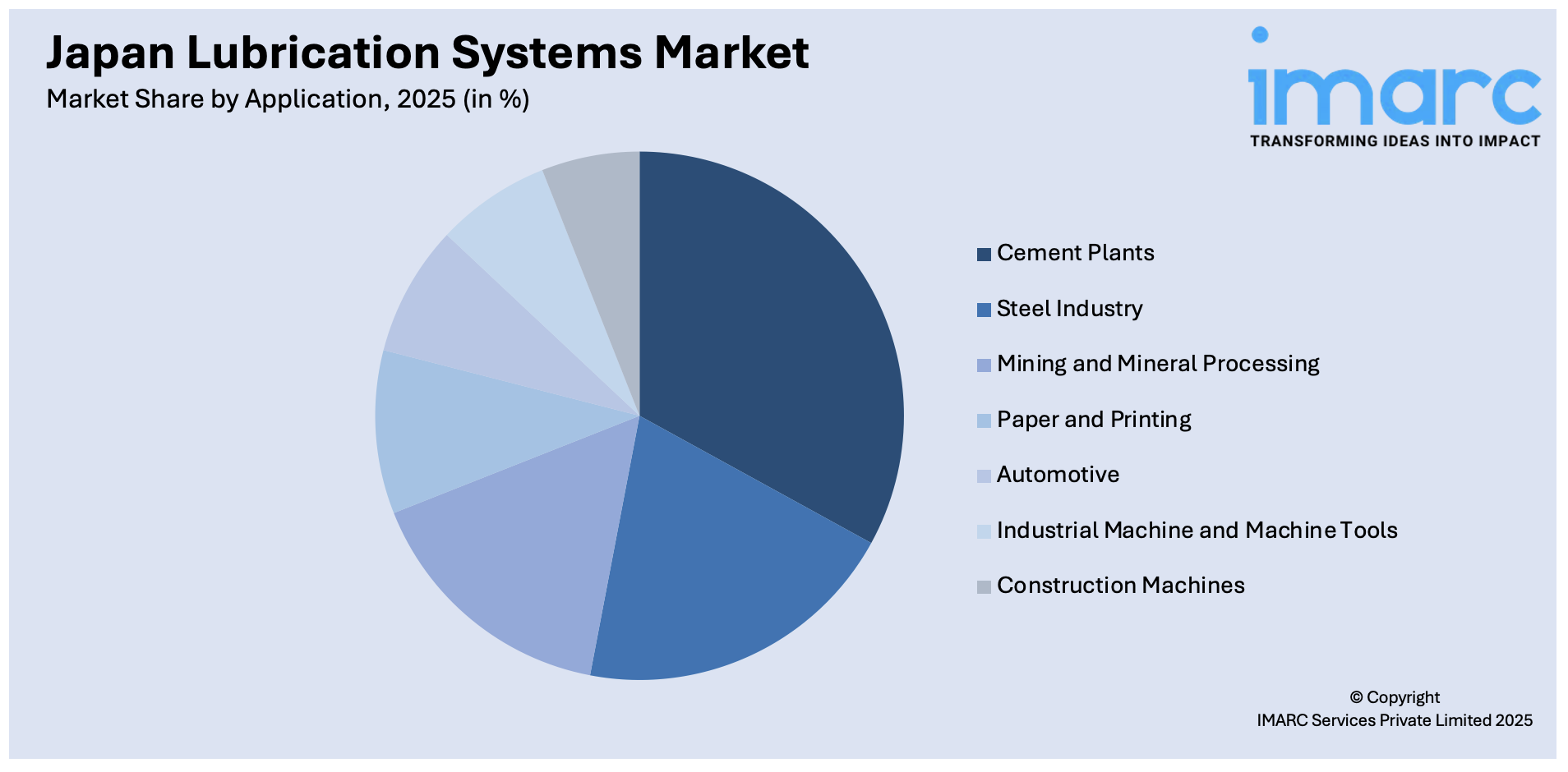

Application Insights:

Access the comprehensive market breakdown Request Sample

- Cement Plants

- Steel Industry

- Mining and Mineral Processing

- Paper and Printing

- Automotive

- Industrial Machine and Machine Tools

- Construction Machines

A detailed breakup and analysis of the market based on the application have also been provided in the report. This includes cement plants, steel industry, mining and mineral processing, paper and printing, automotive, industrial machine and machine tools, and construction machines.

Process Insights:

- Dry Sump Lubrication

- Wet Sump Lubrication

A detailed breakup and analysis of the market based on the process have also been provided in the report. This includes dry sump lubrication and wet sump lubrication.

Regional Insights:

- Kanto Region

- Kansai/Kinki Region

- Central/ Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include the Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, and Shikoku Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Japan Lubrication Systems Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Types Covered |

|

| Applications Covered | Cement Plants, Steel Industry, Mining and Mineral Processing, Paper and Printing, Automotive, Industrial Machine and Machine Tools, Construction Machines |

| Processes Covered | Dry Sump Lubrication, Wet Sump Lubrication |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan lubrication systems market performed so far and how will it perform in the coming years?

- What is the breakup of the Japan lubrication systems market based on type?

- What is the breakup of the Japan lubrication systems market on the basis of application?

- What is the breakup of the Japan lubrication systems market on the basis of process?

- What is the breakup of the Japan lubrication systems market on the basis of region?

- What are the various stages in the value chain of the Japan lubrication systems market?

- What are the key driving factors and challenges in the Japan lubrication systems market?

- What is the structure of the Japan lubrication systems market and who are the key players?

- What is the degree of competition in the Japan lubrication systems market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan lubrication systems market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan lubrication systems market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan lubrication systems industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)