Japan Metal Coatings Market Size, Share, Trends and Forecast by Resin Type, Process, Technology, End Use Industry, and Region, 2026-2034

Japan Metal Coatings Market Overview:

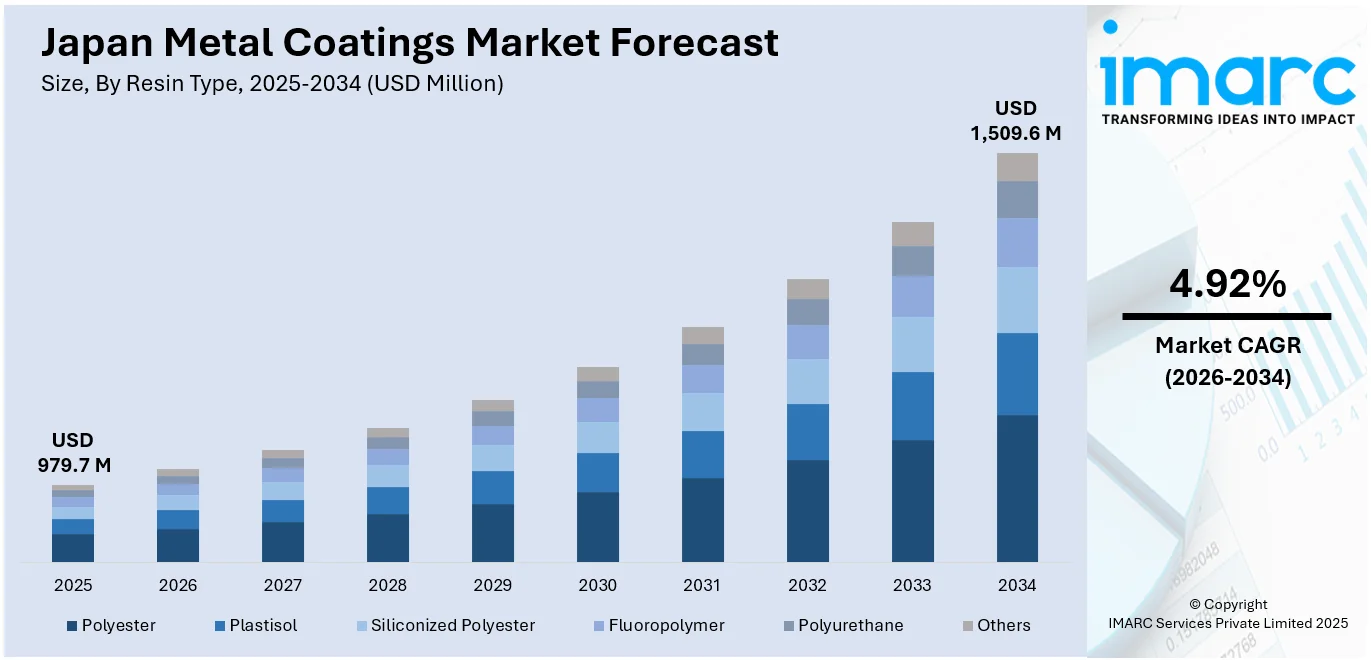

The Japan metal coatings market size reached USD 979.7 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 1,509.6 Million by 2034, exhibiting a growth rate (CAGR) of 4.92% during 2026-2034. The expansion of infrastructure and the growing consumer electronics sector are key drivers of the metal coatings market. Increased demand for durable, high-quality coatings to protect infrastructure and electronic devices from wear, corrosion, and environmental damage strengthens the market growth, with technological advancements further contributing to the expansion of the Japan metal coatings market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025

|

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 979.7 Million |

| Market Forecast in 2034 | USD 1,509.6 Million |

| Market Growth Rate 2026-2034 | 4.92% |

Japan Metal Coatings Market Trends:

Expansion of Infrastructure Development

The expansion of infrastructure development throughout Japan significantly boosts the metal coatings demand, as new construction initiatives lead to a rising need for resilient, high-quality coatings to safeguard steel and metal structures against environmental pressures. Metal coatings play a critical role in preserving the durability and stability of infrastructure like bridges, highways, buildings, and public transit systems. Coatings that provide corrosion prevention, weather protection, and reduced maintenance requirements are crucial for ensuring the safety and longevity of these structures, ultimately lowering long-term expenses. With an increase in public and private investments in infrastructure, the demand for advanced metal coatings is also growing. For example, in 2024, Japan revealed its most significant infrastructure initiative of the year, the expansion of the Tokyo Outer Ring Road (Gaikan Expressway). This 85-kilometer highway aimed to enhance traffic movement, boost economic growth, and facilitate smart city integration. The large scope and bold objectives of initiatives, such as the Gaikan Expressway expansion, generate a significant need for metal coatings that can endure severe environmental conditions, including heavy traffic and extreme weather. With the rise of large-scale infrastructure initiatives, the demand for advanced metal coatings that offer durable protection and affordability is impelling the market growth, establishing the coatings industry as a vital element in Japan’s ongoing infrastructure development.

To get more information on this market Request Sample

Increasing Use in Consumer Electronics

The consumer electronics sector is influencing the Japan metal coatings market growth due to a steady demand for stylish, long-lasting, and visually appealing gadgets. The consumer electronics industry requires high-quality coatings to enhance the appearance and functionality of products while protecting sensitive components from wear, corrosion, and environmental damage. These coatings serve two purposes, providing both aesthetic and protective features, particularly for devices like smartphones, laptops, and televisions (TVs). With the rapid advancement of technology in the consumer electronics industry, the demand for specialized coatings that enhance performance, aesthetics, and durability becomes more significant. The rapid adoption of electronic devices in Japan supports the ongoing growth of the metal coatings industry. For example, the Japan Electronics and Information Technology Industries Association (JEITA) stated that Japan's electronics sector had a total production value of 928,941 million yen in February 2025, totaling 1,788,254 million yen for the whole year of 2025. This notable expansion indicates the growing demand for electronic gadgets, which is directly linked to the heightened requirement for sophisticated coatings. With the increasing production and launch of consumer electronics, the demand for coatings that enhance their functionality, appearance, and longevity is rising, ensuring ongoing need for metal coatings within the electronics sector.

Japan Metal Coatings Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional levels for 2026-2034. Our report has categorized the market based on resin type, process, technology, and end use industry.

Resin Type Insights:

- Polyester

- Plastisol

- Siliconized Polyester

- Fluoropolymer

- Polyurethane

- Others

The report has provided a detailed breakup and analysis of the market based on the resin type. This includes polyester, plastisol, siliconized polyester, fluoropolymer, polyurethane, and others.

Process Insights:

- Coil Coating

- Extrusion Coating

- Hot-Dip Galvanizing

A detailed breakup and analysis of the market based on the process have also been provided in the report. This includes coil coating, extrusion coating, and hot-dip galvanizing.

Technology Insights:

- Liquid Coating

- Powder Coating

The report has provided a detailed breakup and analysis of the market based on the technology. This includes liquid coating and powder coating.

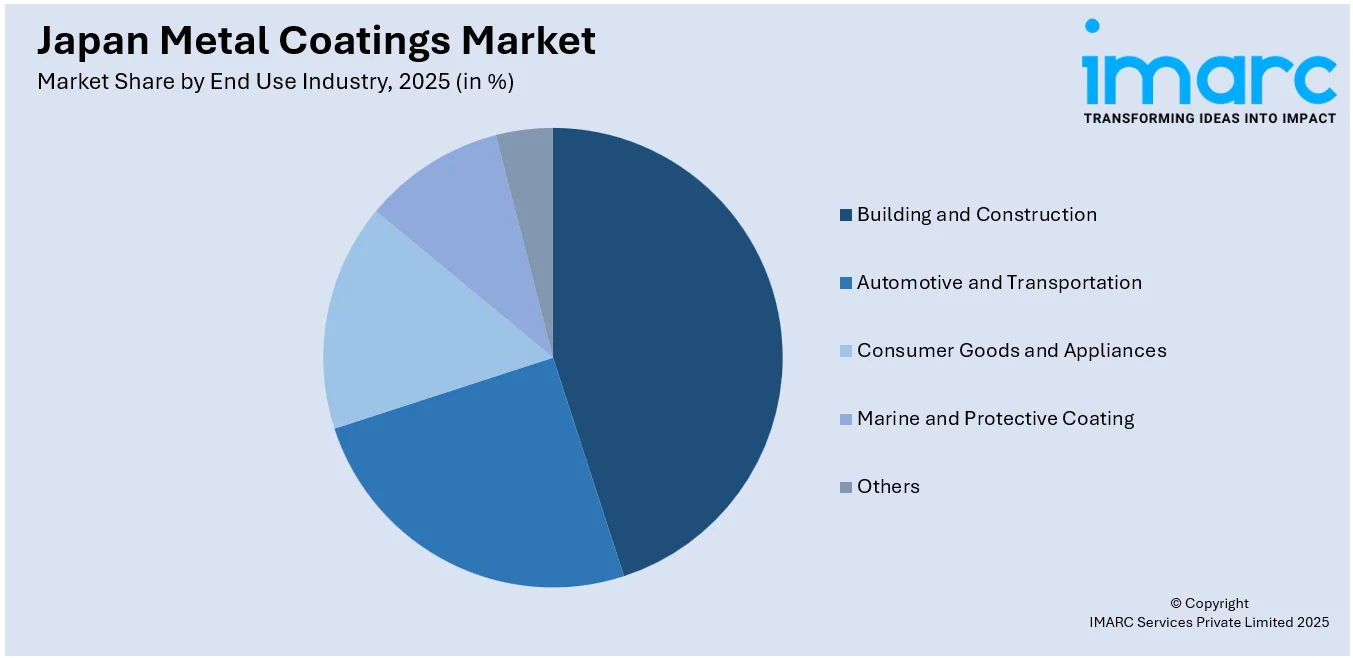

End Use Industry Insights:

Access the comprehensive market breakdown Request Sample

- Building and Construction

- Automotive and Transportation

- Consumer Goods and Appliances

- Marine and Protective Coating

- Others

A detailed breakup and analysis of the market based on the end use industry have also been provided in the report. This includes building and construction, automotive and transportation, consumer goods and appliances, marine and protective coating, and others.

Regional Insights:

- Kanto Region

- Kansai/Kinki Region

- Central/ Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, and Shikoku Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Japan Metal Coatings Market News:

- In January 2025, it was announced that Metal Japan Tokyo Show 2025 will run from November 12–14, at Makuhari Messe, Japan, showcasing high-performance metals and processing technologies. It’s part of Highly-functional Material Week, covering metals, coatings, ceramics, plastics, and more. Ideal for professionals in metal and advanced material industries.

- In September 2024, AkzoNobel introduced the Interpon D Natural Metals range, using patented particle technology for sustainable, metal-effect powder coatings. This innovation delivered deep, metallic finishes without the drawbacks of real metal. The range offered super durable finishes in colors like copper, brass, and steel for architectural use.

Japan Metal Coatings Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Resin Types Covered | Polyester, Plastisol, Siliconized Polyester, Fluoropolymer, Polyurethane, Others |

| Processes Covered | Coil Coating, Extrusion Coating, Hot-Dip Galvanizing |

| Technologies Covered | Liquid Coating, Powder Coating |

| End Use Industries Covered | Building and Construction, Automotive and Transportation, Consumer Goods and Appliances, Marine and Protective Coating, Others |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan metal coatings market performed so far and how will it perform in the coming years?

- What is the breakup of the Japan metal coatings market on the basis of resin type?

- What is the breakup of the Japan metal coatings market on the basis of process?

- What is the breakup of the Japan metal coatings market on the basis of technology?

- What is the breakup of the Japan metal coatings market on the basis of end use industry?

- What is the breakup of the Japan metal coatings market on the basis of region?

- What are the various stages in the value chain of the Japan metal coatings market?

- What are the key driving factors and challenges in the Japan metal coatings market?

- What is the structure of the Japan metal coatings market and who are the key players?

- What is the degree of competition in the Japan metal coatings market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan metal coatings market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan metal coatings market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan metal coatings industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)