Japan Metal Powder Market Size, Share, Trends and Forecast by Material, Technology, Application, and Region, 2026-2034

Japan Metal Powder Market Overview:

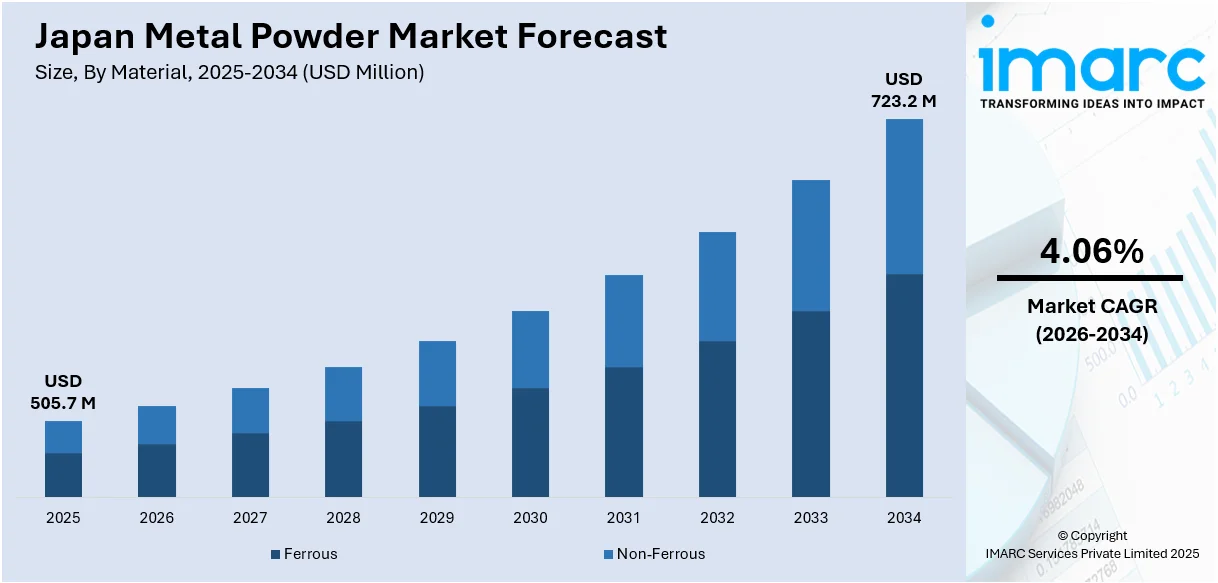

The Japan metal powder market size reached USD 505.7 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 723.2 Million by 2034, exhibiting a growth rate (CAGR) of 4.06% during 2026-2034. The market is experiencing significant growth, driven by advancements in additive manufacturing and the automotive industry's demand for lightweight and fuel-efficient components.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025 |

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 505.7 Million |

| Market Forecast in 2034 | USD 723.2 Million |

| Market Growth Rate 2026-2034 | 4.06% |

Japan Metal Powder Market Trends:

Expanding Utilization of Additive Manufacturing and 3D Printing in Industrial Applications

Additive manufacturing (AM) and metal 3D printing are rapidly reshaping Japan’s manufacturing landscape, fueled by growing demand for high-precision, lightweight components in sectors such as aerospace, automotive, and medical devices. The use of advanced metal powders—titanium, stainless steel, and aluminum—has become integral to AM processes like laser sintering and binder jetting. The growth of the country's metal AM market is supported by strategic government backing. Concurrently, domestic producers such as Daido Steel and JFE Steel are scaling operations—for example, Daido Steel reported a 25% increase in powder metallurgy output in 2024 to meet rising demand from electric vehicle and aerospace manufacturers. This convergence of innovation and traditional "Monozukuri" craftsmanship (a Japanese term, signifies the "art of making things" or "manufacturing" with a deep emphasis on craftsmanship, innovation, and continuous improvement) reflects the country’s evolving industrial identity, where 3D printing enables unprecedented design flexibility and manufacturing efficiency.

To get more information on this market Request Sample

Surge in Demand for Metal Powders in Electric Vehicles (EVs) and Green Technologies

Japan’s ambitious drive toward electrification and carbon neutrality by 2050 is significantly boosting demand for advanced materials, particularly metal powders, which play a critical role in the development of magnetic alloys, battery electrodes, fuel cells, and lightweight structural components. The electric vehicle (EV) sector is a key growth area. Metal powders such as iron, cobalt, and nickel are vital for manufacturing EV motors, battery systems, and electromagnetic interference (EMI) shielding. Simultaneously, metal powders are widely used in automotive lightweighting, with components like powder-forged gears and sintered bearings becoming standard in EV drivetrains. In the energy storage space, companies like Panasonic and Toyota are advancing solid-state battery technologies that rely on ultrafine metal powders to improve ion conductivity and thermal stability. As Japan expands its green energy infrastructure, metal powders are emerging as foundational materials that enhance performance, sustainability, and recyclability across clean technologies.

Japan Metal Powder Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the region/country level for 2026-2034 Our report has categorized the market based on material, technology, and application.

Material Insights:

- Ferrous

- Non-Ferrous

The report has provided a detailed breakup and analysis of the market based on the material. This includes ferrous and non-ferrous.

Technology Insights:

- Pressing and Sintering

- Metal Injection Molding

- Additive Manufacturing

- Others

A detailed breakup and analysis of the market based on the technology have also been provided in the report. This includes pressing and sintering, metal injection molding, additive manufacturing, and others.

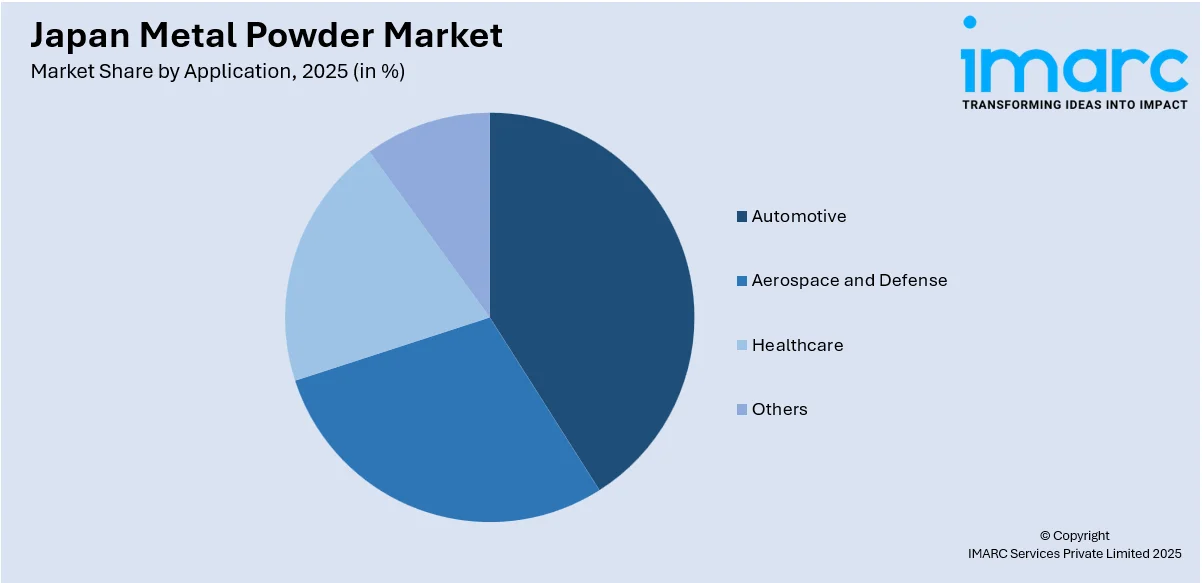

Application Insights:

Access the comprehensive market breakdown Request Sample

- Automotive

- Aerospace and Defense

- Healthcare

- Others

The report has provided a detailed breakup and analysis of the market based on the application. This includes automotive, aerospace and defense, healthcare, and others.

Regional Insights:

- Kanto Region

- Kansai/Kinki Region

- Central/Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Kanto Region, Kansai/Kinki Region, Central/Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, and Shikoku Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Japan Metal Powder Market News:

- February 2025: Nikon Corporation inaugurated the Nikon Additive Manufacturing (AM) Technology Center Japan in Gyoda, Saitama Prefecture. Spanning 922 m², the facility is equipped with advanced metal 3D printing technologies, including the NXG XII 600 Laser Powder Bed Fusion system and the Lasermeister LM300A Directed Energy Deposition system. These systems utilize metal powder to fabricate high-precision components, supporting industries such as defense, aerospace, and manufacturing.

- October 2024: Sun Metalon Inc. secured USD 21 million in Series A funding to advance its proprietary metal powder recycling technology aimed at decarbonizing the metal industry. The company's innovative electromagnetic heating process efficiently converts metal waste into reusable metal powder without melting, reducing energy consumption by up to 85% and potentially achieving zero CO₂ emissions when powered by renewable energy sources.

- January 2024: JFE Steel debuted a new “Insulated Pure-Iron Powder” designed for soft-magnetic composites in axial-gap motors. The powder enables thinner motor cores (48% slimmer) and targets automotive and industrial applications.

Japan Metal Powder Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Materials Covered | Ferrous, Non-Ferrous |

| Technologies Covered | Pressing and Sintering, Metal Injection Molding, Additive Manufacturing, Others |

| Applications Covered | Automotive, Aerospace and Defense, Healthcare, Others |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan metal powder market performed so far and how will it perform in the coming years?

- What is the breakup of the Japan metal powder market on the basis of material?

- What is the breakup of the Japan metal powder market on the basis of technology?

- What is the breakup of the Japan metal powder market on the basis of application?

- What is the breakup of the Japan metal powder market on the basis of region?

- What are the various stages in the value chain of the Japan metal powder market?

- What are the key driving factors and challenges in the Japan metal powder market?

- What is the structure of the Japan metal powder market and who are the key players?

- What is the degree of competition in the Japan metal powder market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan metal powder market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan metal powder market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan metal powder industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)