Japan Metal Sheets Market Size, Share, Trends and Forecast by Material Type, Thickness, Application, and Region, 2026-2034

Japan Metal Sheets Market Overview:

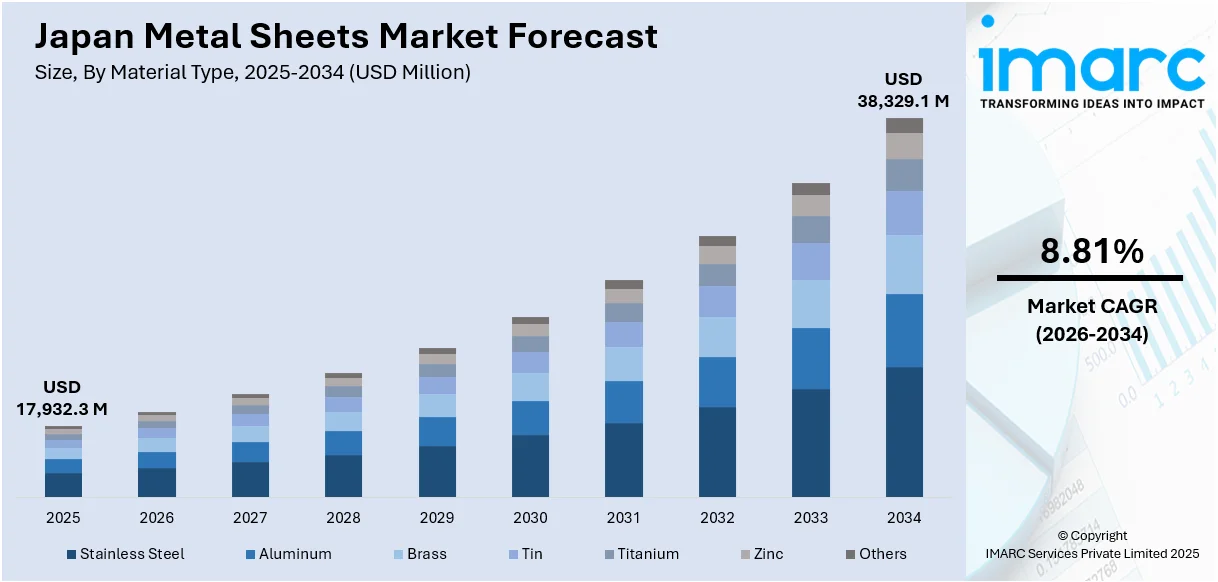

The Japan metal sheets market size reached USD 17,932.3 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 38,329.1 Million by 2034, exhibiting a growth rate (CAGR) of 8.81% during 2026-2034. The market is experiencing change with growing demand for light alloys in sophisticated manufacturing, such as aerospace and electric vehicles (EVs). Urban infrastructure is also fueling uptake of durable, sustainable sheet metals for robust construction. Simultaneously, industrial precision parts demand high-tolerance sheet metals for robotics and electronics. Technology advancements in forming, machining, and surface treatments continue to advance applications in various industries. These relationships as a whole indicate strong growth and innovation in the industry, deepening the Japan metal sheets market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025

|

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 17,932.3 Million |

| Market Forecast in 2034 | USD 38,329.1 Million |

| Market Growth Rate 2026-2034 | 8.81% |

Japan Metal Sheets Market Trends:

Incorporation of Lightweight Alloys in Advanced Production

Japanese manufacturing companies are increasingly incorporating lightweight metal sheet materials like, aluminum, titanium, and magnesium alloys, into their product plans. This trend is particularly notable in the aerospace, automotive, and electronics industries, where weight reduction is imperative for enhancing energy efficiency, performance, and compliance with environmental regulations. Low-weight sheets have superior corrosion resistance, mechanical strength, and good machinability and are best suited for complicated, high-accuracy applications. Their acceptance is also prompted by innovation in rolling and extrusion technologies, which allow manufacturers to create ultra-thin, high-strength sheets with low defects. Moreover, Japan's focus on smart and electric mobility further fuels growth for lightweight solutions to counteract battery weight in EVs. This boosting emphasis on performance and sustainability is in line with larger Japan metal sheets market trends as domestic producers seek technological sophistication and international competitiveness, effectively promoting ongoing Japan metal sheets market growth in value-added industries.

To get more information on this market Request Sample

Metal Sheets in Urban Infrastructure Expansion

The demand for metal sheets in Japan is steadily rising, driven by growing investments in urban infrastructure projects such as public transportation systems, high-rise buildings, and earthquake-resistant construction. Coated metal sheets, high-strength steel, and aluminum panels for architectural use are widely applied in structural components, flooring, cladding, and roofing because of their inherent ruggedness, beauty, and natural disaster resistance. Since urban areas need lightweight materials that are strong, metal sheets provide a feasible and affordable option. In addition, pressure for environmentally friendly building techniques has seen greater use of recyclable and low-emission materials, staying in line with Japan's green construction strategy. Other innovations, like pre-painted and textured sheets, are also adding to architectural versatility. These developments mirror the country's overall shift towards wiser urbanization patterns. Consequently, such development momentum contributes meaningfully to Japan metal sheets market growth and reflects primary Japan metal sheets market trends in infrastructure modernization.

Increased Demand for Precision-Machined Industrial Components

Japan's heightening focus on precision engineering has driven demand for metal sheets in industrial machinery and component manufacturing. Robotic, semiconductor, and automation system industries increasingly depend on sheet metals with thin gauges, cold rolling, and high tolerance for smooth finishes and precise measurements where required. For instance, in October 2024, JX Advanced Metals went public by filing for IPO to enhance emphasis on advanced materials, in concurrence with growth in Japan's metal sheets market owing to increasing demand in automotive, electronics, and semiconductors sectors. Moreover, the materials provide high-performance outputs in sophisticated manufacturing processes. Advanced CNC machining, laser cutting, and stamping technologies are assisting the manufacture of delicate components from sheets of stainless steel, brass, and titanium, which possess exceptional heat resistance and machinability. Pursuing further digitalization and miniaturization of electrical and mechanical goods further boosts sheet metal usage in connectors, shields, and casings. This fits into Japan's wider industrial evolution and Japan's commitment to quality, precision, and productivity. As a result, demand for technologically advanced materials has emerged as a leading driver of Japan metal sheets market growth, reflecting new Japan metal sheets market trends in high-value industrial applications.

Japan Metal Sheets Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional levels for 2026-2034. Our report has categorized the market based on material type, thickness, and application.

Material Type Insights:

- Stainless Steel

- Aluminum

- Brass

- Tin

- Titanium

- Zinc

- Others

The report has provided a detailed breakup and analysis of the market based on the material type. This includes stainless steel, aluminum, brass, tin, titanium, zinc, and others.

Thickness Insights:

- < 1 mm

- 1-6 mm

- > 6mm

A detailed breakup and analysis of the market based on the thickness have also been provided in the report. This includes < 1 mm, 1–6 mm, and > 6 mm.

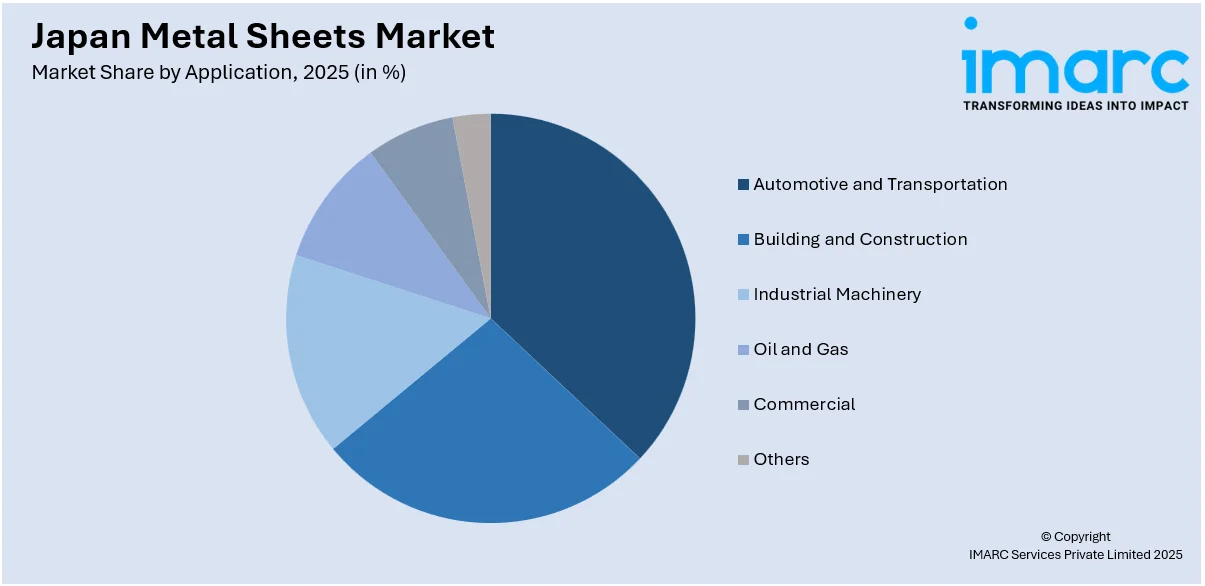

Application Insights:

Access the comprehensive market breakdown Request Sample

- Automotive and Transportation

- Building and Construction

- Industrial Machinery

- Oil and Gas

- Commercial

- Others

The report has provided a detailed breakup and analysis of the market based on the application. This includes automotive and transportation, building and construction, industrial machinery, oil and gas, commercial, and others.

Regional Insights:

- Kanto Region

- Kansai/Kinki Region

- Central/ Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Kanto region, Kansai/Kinki region, Central/Chubu region, Kyushu-Okinawa region, Tohoku region, Chugoku region, Hokkaido region, and Shikoku region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Japan Metal Sheets Market News:

- In February of 2025, Baoshan Iron & Steel, Baowu Aluminum Technology, and Kobe Steel of Japan formally opened their joint venture, Kobelco Baosteel, in Shanghai. The deal is centered on developing sustainable automotive aluminum sheets to boost supply and market share in China and Japan.

Japan Metal Sheets Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Material Types Covered | Stainless Steel, Aluminum, Brass, Tin, Titanium, Zinc, Others |

| Thicknesses Covered | < 1 mm, 1–6 mm, > 6 mm |

| Applications Covered | Automotive and Transportation, Building and Construction, Industrial Machinery, Oil and Gas, Commercial, Others |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan metal sheets market performed so far and how will it perform in the coming years?

- What is the breakup of the Japan metal sheets market on the basis of material type?

- What is the breakup of the Japan metal sheets market on the basis of thickness?

- What is the breakup of the Japan metal sheets market on the basis of application?

- What is the breakup of the Japan metal sheets market on the basis of region?

- What are the various stages in the value chain of the Japan metal sheets market?

- What are the key driving factors and challenges in the Japan metal sheets?

- What is the structure of the Japan metal sheets market and who are the key players?

- What is the degree of competition in the Japan metal sheets market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan metal sheets market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan metal sheets market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan metal sheets industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)