Japan Pneumatic Tools Market Size, Share, Trends and Forecast by Type, Application, End-Use, and Region, 2026-2034

Japan Pneumatic Tools Market Overview:

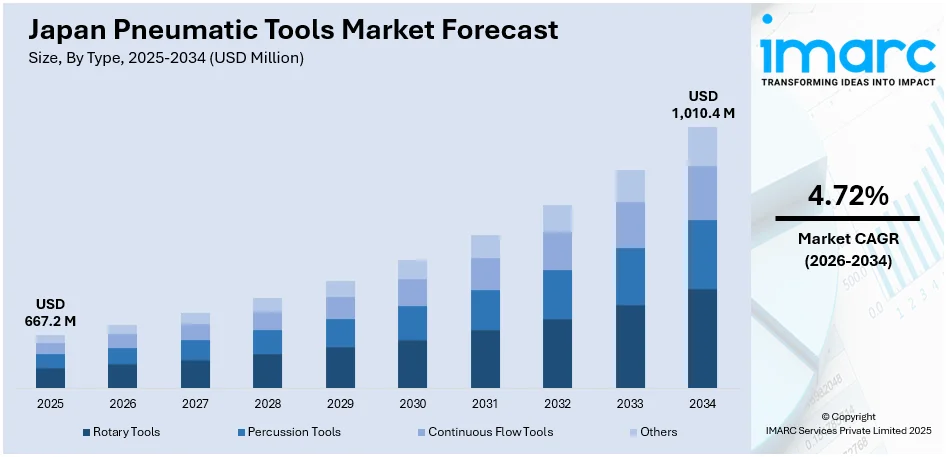

The Japan pneumatic tools market size reached USD 667.2 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 1,010.4 Million by 2034, exhibiting a growth rate (CAGR) of 4.72% during 2026-2034. The market is driven by the rising adoption of electric-pneumatic hybrid tools, which enhance energy efficiency and reduce operational costs, particularly in automotive and aerospace industries. Additionally, stringent environmental regulations and corporate sustainability initiatives are accelerating the shift toward advanced pneumatic solutions. The integration of IoT-enabled smart tools, enabling predictive maintenance and real-time performance optimization, is further augmenting the Japan pneumatic tools market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025 |

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 667.2 Million |

| Market Forecast in 2034 | USD 1,010.4 Million |

| Market Growth Rate 2026-2034 | 4.72% |

Japan Pneumatic Tools Market Trends:

Expansion of Pneumatic Tools in Robotics and Automation

The market is expanding rapidly in robotics and automation applications, supported by the country’s leadership in industrial robotics. Japan's manufacturing robotics industry continues to grow, with a total of 435,299 robots in operation at plants, representing a 5% increase. Although there has been a 9% decline in new installations, from 46,106 units in 2023, Japan remains the second-largest market globally for robots. The persistent high demand from sectors such as the automobile and electronics industries justifies the need for high-tech pneumatic tools in robotics production and maintenance, thus encouraging innovation and enhancing efficiency in Japanese manufacturing. Pneumatic grippers, actuators, and clamping systems are increasingly integrated into automated production lines, offering high-speed, reliable performance in pick-and-place and assembly tasks. The automotive and electronics sectors, in particular, are leveraging these tools for their precision and cost-effectiveness compared to purely electric alternatives. Advances in compact, high-force pneumatic components are enabling their use in collaborative robots (cobots), further broadening adoption. With Japan’s manufacturing sector accelerating automation to counter labor shortages, pneumatic tools are becoming indispensable in smart factories. This trend is expected to strengthen as Industry 4.0 adoption grows, sustaining long-term demand for pneumatic solutions in automated systems.

To get more information on this market Request Sample

Growth of Smart Pneumatic Tools with IoT Integration

The increasing integration of IoT (Internet of Things) technology, enabling smart monitoring and predictive maintenance, is propelling the Japan pneumatic tools market growth. Advanced pneumatic tools now come equipped with sensors that track performance metrics such as air pressure, vibration, and usage patterns in real time. This data is transmitted to centralized systems, allowing operators to optimize efficiency and prevent unexpected breakdowns. Industries such as manufacturing and logistics are adopting these smart tools to enhance productivity and reduce downtime. Japanese manufacturers are leading this innovation by developing AI-driven diagnostics and automated adjustment features. Furthermore, the rise of Industry 4.0 and smart factories in Japan is fueling demand for connected pneumatic systems. Japan's Society 5.0 vision, moving beyond Industry 4.0, embraces the Internet of Things, artificial intelligence, and robotics to transform key industries including transportation, healthcare, and infrastructure, supported by a ¥4.2 trillion (USD 38 Billion) science, technology, and innovation budget in 2019. With smart infrastructure and automation at the center of this digital revolution, pneumatic tools manufacturers are likely to see increased demand for intelligent, cyber-physical systems. This program also supports Japan's sustainability efforts and alignment with the Sustainable Development Goals, which will be strongly showcased at EXPO 2025 in Osaka. As businesses seek data-driven insights to improve operational workflows, IoT-enabled pneumatic tools are becoming a critical component of modern industrial equipment.

Japan Pneumatic Tools Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional levels for 2026-2034. Our report has categorized the market based on type, application, and end-use.

Type Insights:

- Rotary Tools

- Percussion Tools

- Continuous Flow Tools

- Others

The report has provided a detailed breakup and analysis of the market based on the type. This includes rotary tools, percussion tools, continuous flow tools, and others.

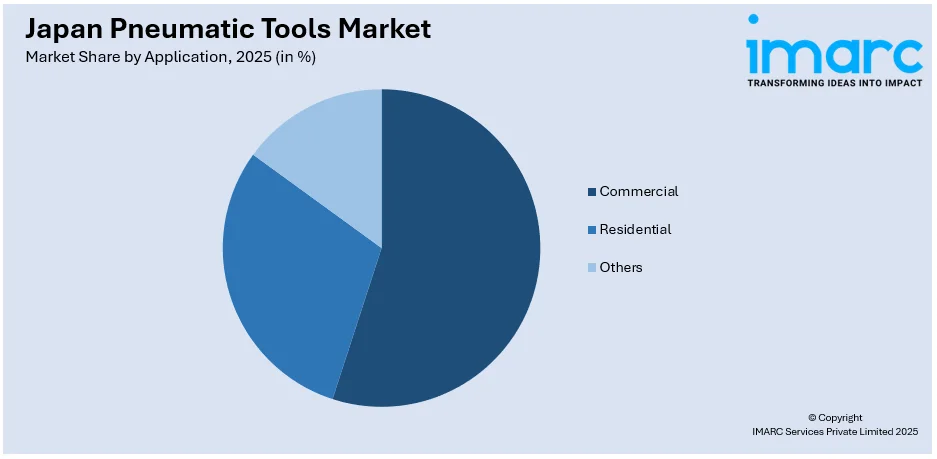

Application Insights:

Access the comprehensive market breakdown Request Sample

- Commercial

- Residential

- Others

A detailed breakup and analysis of the market based on the application have also been provided in the report. This includes commercial, residential, and others.

End-Use Insights:

- Manufacturing Industry

- Automotive Industry

- Construction Industry

- Others

The report has provided a detailed breakup and analysis of the market based on the end-use. This includes manufacturing industry, automotive industry, construction industry, and others.

Regional Insights:

- Kanto Region

- Kansai/Kinki Region

- Central/ Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, and Shikoku Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Japan Pneumatic Tools Market News:

- March 26, 2025: BENZ Packaging introduced WELL AIR, an innovative compressed air purification system developed in partnership with Kamata Tecnas, a technology firm based in Japan. This system efficiently removes 99.9% of moisture, thereby enhancing the efficiency and lifespan of pneumatic tools, reducing cutting downtime and maintenance needs. This synergy blends cutting-edge Japanese technology with green design, creating a revolutionary solution for the Japanese pneumatic tools industry and other markets.

Japan Pneumatic Tools Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Types Covered | Rotary Tools, Percussion Tools, Continuous Flow Tools, Others |

| Applications Covered | Commercial, Residential, Others |

| End-Uses Covered | Manufacturing Industry, Automotive Industry, Construction Industry, Others |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan pneumatic tools market performed so far and how will it perform in the coming years?

- What is the breakup of the Japan pneumatic tools market on the basis of type?

- What is the breakup of the Japan pneumatic tools market on the basis of application?

- What is the breakup of the Japan pneumatic tools market on the basis of end-use?

- What is the breakup of the Japan pneumatic tools market on the basis of region?

- What are the various stages in the value chain of the Japan pneumatic tools market?

- What are the key driving factors and challenges in the Japan pneumatic tools market?

- What is the structure of the Japan pneumatic tools market and who are the key players?

- What is the degree of competition in the Japan pneumatic tools market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan pneumatic tools market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan pneumatic tools market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan pneumatic tools industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)