Japan Water Pipeline Leak Detection System Market Size, Share, Trends and Forecast by Technology, Equipment, Pipe Type, End-Use, and Region, 2026-2034

Japan Water Pipeline Leak Detection System Market Overview:

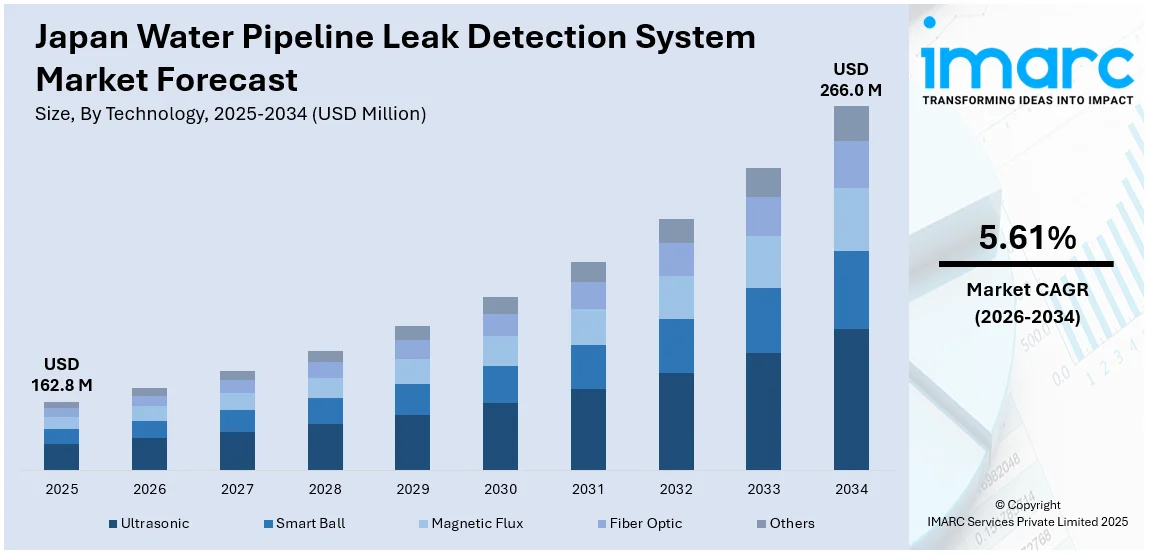

The Japan water pipeline leak detection system market size reached USD 162.8 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 266.0 Million by 2034, exhibiting a growth rate (CAGR) of 5.61% during 2026-2034. The market is driven by aging water infrastructure, rising demand for efficient water management solutions, government regulations promoting sustainability, and rising water scarcity concerns. In addition to this, continual technological advancements in IoT, AI, rapid urbanization, growing need to prevent water wastage and reduce maintenance costs across urban areas are some of the major factors augmenting the Japan water pipeline leak detection system market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025 |

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 162.8 Million |

| Market Forecast in 2034 | USD 266.0 Million |

| Market Growth Rate 2026-2034 | 5.61% |

Japan Water Pipeline Leak Detection System Market Trends:

Increasing Adoption of Advanced IoT-Based Leak Detection Systems

The market is witnessing a significant shift toward IoT-based solutions. A research report from the IMARC Group indicates that the industrial IoT market in Japan achieved a size of USD 6.9 Billion in 2024. Projections suggest that this market will expand to USD 15.6 Billion by 2033, reflecting a compound annual growth rate (CAGR) of 9.6% from 2025 to 2033. This expansion is anticipated to foster innovations in water management technologies, such as IoT-enabled systems for detecting leaks in water pipelines, thereby improving infrastructure efficiency throughout Japan. With aging infrastructure and increasingly scarce water resources creating challenges, utilities and municipalities are turning to advanced leak detection technologies. IoT-enabled sensors are used for real-time monitoring as well as quick detection of leaks to reduce water loss. These systems utilize artificial intelligence and machine learning to analyze data patterns, improving precision and minimizing false alerts. Moreover, additional subsidies and an enabling policy environment from the Japanese government also drive smart water management practices. Organizations are investing in R&D to enhance sensor robustness and connectivity to ensure reliable performance in different terrains. As urban populations grow, the demand for efficient water management systems is rising, further supporting the Japan water pipeline leak detection system market growth.

To get more information on this market Request Sample

Integration of Green Hydrogen Production with Water Leak Detection Systems

Japan's push toward a carbon-neutral future is driving the convergence of water pipeline leak detection systems with green hydrogen infrastructure. As the country invests heavily in hydrogen energy, ensuring efficient water supply for electrolysis becomes critical. Advanced leak detection technologies help minimize water loss in pipelines feeding electrolyzers, optimizing resource use for hydrogen production. The government's Green Growth Strategy supports this synergy, promoting smart water management in hydrogen hubs. On December 18, 2024, Asahi Kasei secured government approval to expand its production of machinery for green hydrogen production. The company plans to increase production to up to 2 GW per year starting in 2028 at its Kawasaki facility. This effort ties into Japan's "Green Transformation" program that aims to achieve carbon neutrality in 2050. As the demand for green hydrogen continues to grow, the increase in water electrolyzer production complements the broader national goals. It highlights the commitment to sustainable technologies across the domains of both water management and energy generation. Companies are also developing hybrid systems that monitor pipeline integrity while supporting sustainable hydrogen production. With Japan aiming to lead in green hydrogen, the integration of leak prevention in water networks is playing a key role in maintaining supply chain efficiency. Thus, this is further creating a positive Japan water pipeline leak detection system market outlook.

Japan Water Pipeline Leak Detection System Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country level for 2026-2034. Our report has categorized the market based on technology, equipment, pipe type, and end-use.

Technology Insights:

- Ultrasonic

- Smart Ball

- Magnetic Flux

- Fiber Optic

- Others

The report has provided a detailed breakup and analysis of the market based on the technology. This includes ultrasonic, smart ball, magnetic flux, fiber optic, and others.

Equipment Insights:

- Acoustic

- Non-Acoustic

A detailed breakup and analysis of the market based on the equipment have also been provided in the report. This includes acoustic and non-acoustic.

Pipe Type Insights:

- Plastic Pipes

- Ductile Iron Pipes

- Stainless Steel Pipes

- Aluminium Pipes

- Others

The report has provided a detailed breakup and analysis of the market based on the pipe type. This includes plastic pipes, ductile iron pipes, stainless steel pipes, aluminium pipes, and others.

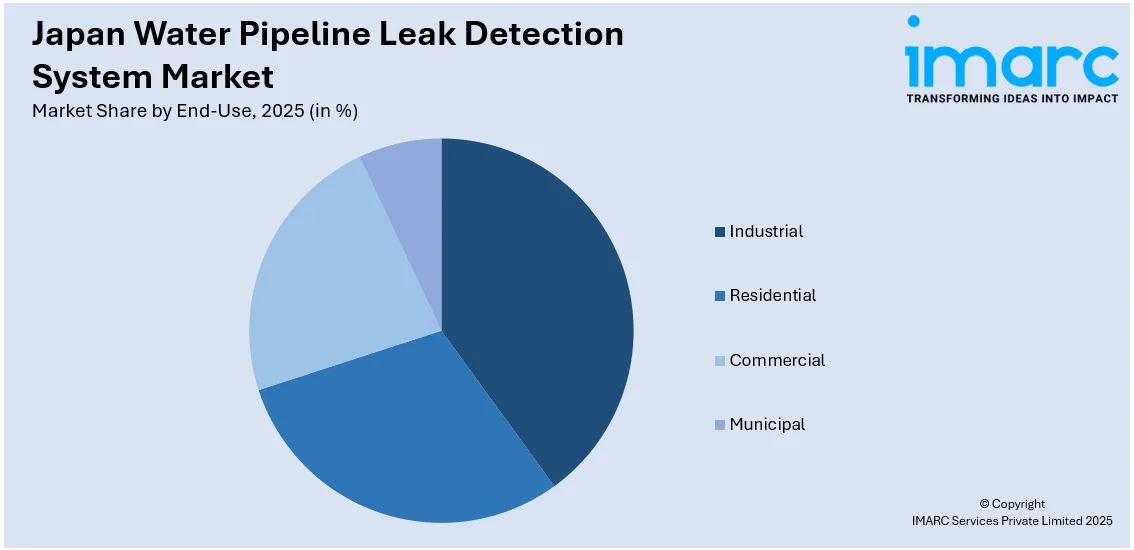

End-Use Insights:

Access the comprehensive market breakdown Request Sample

- Industrial

- Residential

- Commercial

- Municipal

A detailed breakup and analysis of the market based on the end-use have also been provided in the report. This includes industrial, residential, commercial, and municipal.

Regional Insights:

- Kanto Region

- Kansai/Kinki Region

- Central/ Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, and Shikoku Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Japan Water Pipeline Leak Detection System Market News:

- June 11, 2024: SwitchBot introduced a Water Leak Detector, complete with advanced leak detection functionality as well as Bluetooth and Wi-Fi connectivity, that can alert users in real-time for USD 17.99. With its 3-in-1 detection for features such as water drips, immersion, and levels, it's an early warning system featuring sensors that can detect just 0.5 mm of water. The ability to withstand the rigors of everyday installation, with an aanIP67 waterproofing class rating, makes it ideal for both domestic and commercial applications, as well as meets the increasing demand in Japan for high-end electronic water leak detection systems to prevent costly water damage.

Japan Water Pipeline Leak Detection System Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Technologies Covered | Ultrasonic, Smart Ball, Magnetic Flux, Fiber Optic, Others |

| Equipments Covered | Acoustic, Non-Acoustic |

| Pipe Types Covered | Plastic Pipes, Ductile Iron Pipes, Stainless Steel Pipes, Aluminium Pipes, Others |

| End-Uses Covered | Industrial, Residential, Commercial, Municipal |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan water pipeline leak detection system market performed so far and how will it perform in the coming years?

- What is the breakup of the Japan water pipeline leak detection system market on the basis of technology?

- What is the breakup of the Japan water pipeline leak detection system market on the basis of equipment?

- What is the breakup of the Japan water pipeline leak detection system market on the basis of pipe type?

- What is the breakup of the Japan water pipeline leak detection system market on the basis of end-use?

- What is the breakup of the Japan water pipeline leak detection system market on the basis of region?

- What are the various stages in the value chain of the Japan water pipeline leak detection system market?

- What are the key driving factors and challenges in the Japan water pipeline leak detection system market?

- What is the structure of the Japan water pipeline leak detection system market and who are the key players?

- What is the degree of competition in the Japan water pipeline leak detection system market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan water pipeline leak detection system market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan water pipeline leak detection system market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan water pipeline leak detection system industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)