Magnet Market Report by Magnet Type (Ferrite, Neodymium Iron Boron (NdFeB), Aluminium Nickel Cobalt (AlNiCo), Samarium Cobalt (SmCo)), Application (Computer Hard Disk Drives (HDD), CD, DVD, Hybrid Electric Vehicles, Electric Bicycles, Heating, Ventilating and Air Conditioners (HVAC), Wind Turbines, and Other Applications), and Country 2025-2033

Magnet Market Size:

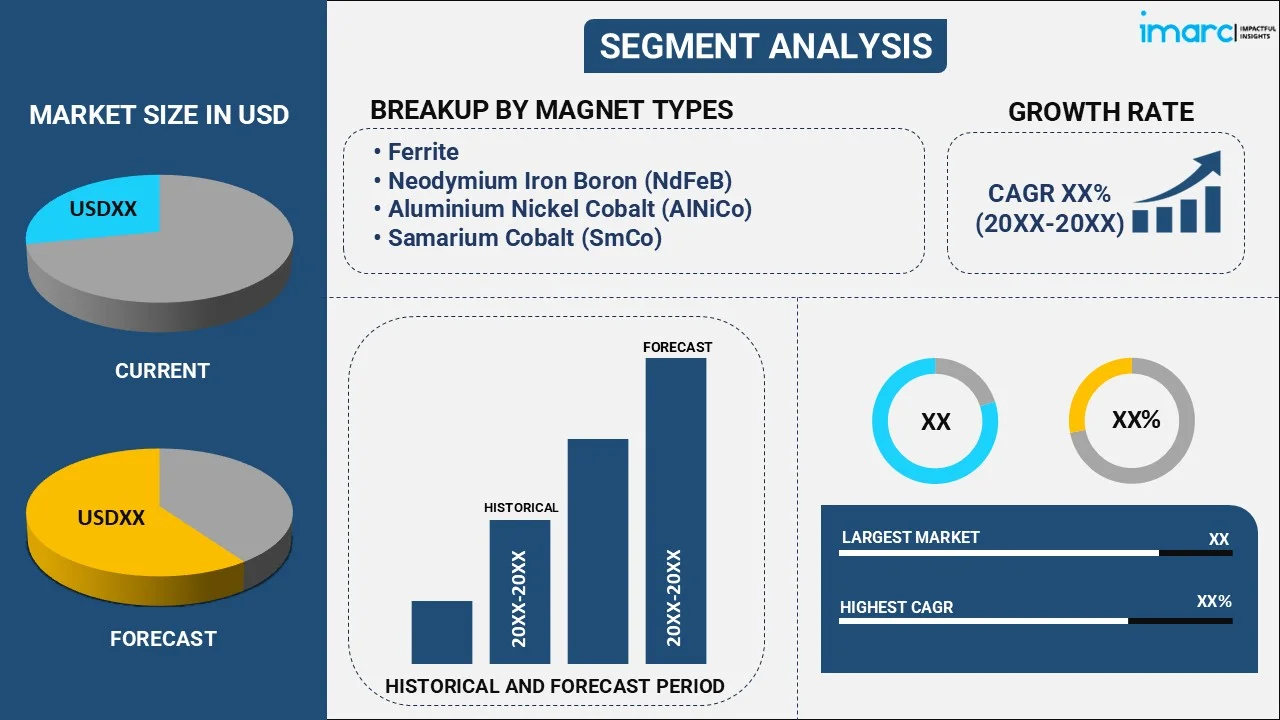

The global magnet market size reached USD 41.75 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 58.7 Billion by 2033, exhibiting a growth rate (CAGR) of 3.82% during 2025-2033. China currently dominates the market owing to the growing rapidly driven by increasing product demand in the automotive industry, recent advancements in electronics and consumer goods, significant growth in the wind energy sector, rapid technological innovations, and widespread adoption of automation and robotics.

Market Size & Forecasts:

- Magnet market was valued at USD 41.75 Billion in 2024.

- The market is projected to reach USD 58.7 Billion by 2033, at a CAGR of 3.82% from 2025-2033.

Dominant Segments:

- Magnet Type: Neodymium iron boron (NdFeB) leads the market, on the basis of magnet type, because it exhibits the strongest magnetic strength of any available commercial magnet, making it ideal for compact, high-performance uses in electronics, automotive, and industrial equipment.

- Application: Computer hard disk drives (HDD), CD, DVD account for the largest market share as they need precise, high-strength magnets for efficient data reading and writing, and continue to be widely utilized in data storage, backup solutions, and multimedia devices.

- Region: China dominates the market due to its dominance in rare earth mineral production, large manufacturing base, and strong domestic demand across electronics, automotive, and energy sectors, enabling it to produce and export magnets at scale and competitive cost.

Key Players:

- The leading companies in magnet market include Adams Magnetic Products, LLC, Arnold Magnetic Technologies, BGRIMM Technology Group, Daido Kogyo Co., Ltd., DMEGC, Electron Energy Corporation, Goudsmit Magnetics, Lynas Rare Earths Ltd, Magnequench International, LLC, Proterial, Ltd, Shin-Etsu Chemical Co., Ltd., TDK Corporation, Yantai Dongxing Magnetic Materials Inc, etc.

Key Drivers of Market Growth:

- Miniaturization and High Performance Requirements: These requirements are driving the demand for compact, powerful magnets that fit into smaller devices. These magnets support advanced functions in electronics, medical tools, and aerospace systems where space and efficiency are critical.

- Advancements in Medical Technology: Magnetic resonance imaging (MRI) machines and modern medical devices rely on strong magnets for accurate imaging and functionality. Increasing healthcare needs are catalyzing the demand for reliable, high-performance magnets in diagnostic and therapeutic equipment.

- Increasing Demand for Energy Efficiency: Industries are using magnets in motors and generators to reduce power utilization. These magnets help create compact, high-efficiency systems, supporting global efforts to lower energy use and environmental impact.

- Rapid Urbanization and Smart City Development: As cities are becoming more connected, magnets play a key role in various applications, including transportation systems, energy-efficient buildings, smart grids, and public safety equipment. From automated transit systems and electric buses to smart meters and surveillance devices, magnets help ensure reliable operation and performance.

- Growth in Marine Industry: Ships, submarines, and offshore platforms rely on magnets in navigation systems, electric propulsion, communication devices, and control equipment. Magnets are essential in motors, sensors, and actuators that operate in harsh marine environments, where reliability and efficiency are critical.

Future Outlook:

- Strong Growth Outlook: The magnet market is expected to see sustained expansion, driven by high demand in electric vehicles (EVs), medical devices, and automation. Continued innovations, sustainability focus, and global industrial growth ensure steady expansion across multiple high-performance application areas.

- Market Evolution: The sector is anticipated to shift from basic magnetic materials to advanced rare earth and high-performance magnets, driven by innovations and industrial demand. It is supporting compact, energy-efficient technologies across sectors like automotive, energy, healthcare, and electronics, reflecting continuous technological advancements.

The magnet market is expanding steadily due to increasing demand across various industries that rely on advanced magnetic technologies for improved performance, efficiency, and innovation. One key driver is the growth of renewable energy, especially wind turbines, which use high-strength magnets in their generators to produce clean power. The ongoing shift towards energy efficiency is positively influencing the market, as magnets enable compact, powerful motors and systems that reduce energy utilization in appliances, machinery, and industrial equipment. Advancements in medical technology are further catalyzing the demand, with MRI machines, implantable devices, and diagnostic tools relying on precise and powerful magnets. Miniaturization trends in technology create a need for smaller, high-performance magnets that fit into compact systems without sacrificing output. The growth of industrial automation and robotics is increasing the use of magnets in sensors, actuators, and motion control systems. Smart home devices and infrastructure also depend on magnets for locks, sensors, and smart utility systems. Technological progress in magnet manufacturing, such as rare earth magnet development and recycling methods, enhances magnet quality while lowering costs.

To get more information on this market, Request Sample

Magnet Market Trends:

Increasing adoption of EVs

Rising adoption of EVs is fueling the market growth. As per industry reports, the worldwide EV market soared to unprecedented levels in 2024, achieving a 25% annual growth and resulting in 17.1 Million EVs sold globally. EVs rely heavily on permanent magnets, especially in electric motors, which are essential for converting electrical energy into mechanical motion. These magnets help improve motor efficiency, reduce energy loss, and enhance overall vehicle performance. In addition to motors, magnets are used in sensors, battery systems, regenerative braking, and auxiliary functions like window motors. As government agencies and people are shifting towards cleaner transportation, the production of EVs continues to rise, leading automakers to source large volumes of high-performance magnets. This growing need is making magnets a critical component in the EV supply chain.

Growing use in consumer electronics

Increasing use in consumer electronics is positively influencing the market. As per industry reports, the global consumer electronics market size was valued at USD 949.7 Billion in 2024. Modern devices, such as smartphones, tablets, laptops, headphones, and smartwatches, rely on magnets for various functions, including audio output, vibration alerts, magnetic charging, and secure closures. Magnets are also used in camera modules, haptic feedback systems, and speakers, which require precise and reliable magnetic properties. As technology is advancing, user expectations for smaller, faster, and more feature-rich devices are motivating manufacturers to employ stronger and lighter magnets. The rise of smart home devices, including smart locks, thermostats, and speakers, is adding further to this demand.

Expansion of the aerospace and defense sectors

The expansion of the aerospace and defense sectors is offering a favorable market outlook. Magnets play a critical role in applications, such as navigation systems, radar equipment, actuators, electric propulsion, and control systems, in both aircraft and defense technologies. These components must perform efficiently under extreme conditions, including high temperatures, pressure, and vibration. Magnets are also essential in satellite systems, drones, and missile guidance technologies, where precision and durability are vital. As countries are investing in strengthening their defense capabilities and expanding their aerospace programs, the demand for sophisticated, lightweight, and compact magnetic materials is rising. This steady growth in aerospace and defense applications is making magnets a crucial part of innovations and development. According to industry reports, the worldwide aerospace market is expected to attain approximately USD 791.78 Billion by 2034.

Key Growth Drivers of Magnet Market:

Miniaturization and high performance requirements

Miniaturization and high performance requirements are driving the demand for compact, efficient magnetic components. As modern technology is evolving, industries are seeking smaller, lighter, and more powerful devices that do not compromise on functionality. This trend is creating the need for high-strength magnets capable of delivering reliable performance in tight, limited spaces. These compact magnets are essential in applications, such as smartphones, medical implants, EVs, and aerospace systems, where space and weight are critical constraints. Devices in these sectors rely on advanced magnetic solutions to ensure precision, efficiency, and durability. As products are becoming more complex and compact, manufacturers continue to turn to specialized magnets that meet strict performance standards, making miniaturization and performance demands key factors driving sustained growth in the global magnet market.

Advancements in medical technology

Advancements in medical technology are propelling the market growth. MRI scanners, which are essential for non-invasive internal body imaging, depend on powerful magnets to generate detailed and accurate results. As the demand for advanced diagnostic tools is rising, the need for high-performance magnets is increasing. In addition to MRI, magnets are widely used in various medical devices, such as hearing aids, insulin pumps, and surgical tools, as well as in implantable technologies like pacemakers. Diagnostic equipment and rehabilitation devices also integrate magnetic components for improved functionality and precision. With ongoing innovations in healthcare and a growing focus on patient-centered solutions, the medical field continues to rely on advanced magnets, supporting steady and long-term demand in the global magnet market.

Rising demand for energy efficiency

The growing demand for energy efficiency is positively influencing the market. Magnets play a crucial role in improving energy optimization by enabling the development of compact, lightweight, and powerful motors and generators. These magnetic components help machines operate with less energy while delivering the same or better performance, making them ideal for applications in EVs, household appliances, wind turbines, and industrial machinery. As global efforts to lower carbon emissions are intensifying, more sectors are adopting magnet-based technologies to achieve higher efficiency and meet sustainability goals. The ability of magnets to enhance performance without increasing energy usage makes them a key solution in modern energy-saving systems, further catalyzing their demand across a wide range of energy-conscious applications.

Magnet Industry Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the global, regional, and country levels for 2025-2033. Our report has categorized the market based on magnet type and application.

Breakup by Magnet Type:

- Ferrite

- Neodymium Iron Boron (NdFeB)

- Aluminium Nickel Cobalt (AlNiCo)

- Samarium Cobalt (SmCo)

Neodymium iron boron (NdFeB) accounts for the majority of the market share

The report has provided a detailed breakup and analysis of the market based on the magnet type. This includes ferrite, neodymium iron boron (NdFeB), aluminium nickel cobalt (AlNiCo), and samarium cobalt (SmCo). According to the report, neodymium iron boron (NdFeB) represented the largest segment.

Neodymium Iron Boron (NdFeB) magnets hold the largest market segment owing to their exceptional magnetic strength and performance. They are a type of rare earth magnet made from an alloy of neodymium, iron, and boron. NdFeB magnets have the highest magnetic field strength and energy product among all permanent magnets, making them ideal for applications requiring compact size and strong magnetic fields, such as in electric vehicles, wind turbines, and hard disk drives. Furthermore, their superior properties drive their widespread adoption in advanced technological applications. Besides this, the increasing emphasis on high-efficiency, compact, and powerful magnetic solutions in various industries, is supporting the market growth.

Ferrite magnets, also known as ceramic magnets, are widely used due to their cost-effectiveness and moderate magnetic strength. They are composed of iron oxide and barium or strontium carbonate, offering good resistance to demagnetization and corrosion. Ferrite magnets are popular in applications where a strong magnetic field is not essential, such as in small motors, speakers, and magnetic resonance imaging (MRI) equipment.

Aluminium nickel cobalt (AlNiCo) magnets are known for their excellent temperature stability and resistance to demagnetization. They are commonly used in applications where a stable performance over a wide temperature range is essential, such as in aerospace, military, and automotive sensors. AlNiCo magnets are also popular in the manufacturing of electric guitar pickups due to their unique magnetic field characteristics.

Samarium cobalt (SmCo) magnets are known for their high magnetic strength and exceptional thermal stability. They are particularly suited for applications in extreme working temperatures or where space is limited. SmCo magnets are highly resistant to oxidation and typically do not require a protective coating. They are commonly used in aerospace, military, and high-performance motors.

Breakup by Application:

- Computer Hard Disk Drives (HDD), CD, DVD

- Hybrid Electric Vehicles

- Electric Bicycles

- Heating, Ventilating and Air Conditioners (HVAC)

- Wind Turbines

- Other Applications

- Transducers and Loudspeakers

- Magnetic Separation Equipment and Sorters

- Magnetic Resonance Imaging (MRI)

- Magnetic Braking Systems

- Magnetically Levitated Transportation Systems

- Medicine and Health

- Credit Cards and other ID Cards

- Traveling Waves Tubes (TWT)

- Advertising and Promotional Products

- Magnetic Refrigeration system

- Nanotechnology

- Military and Aerospace

- Energy Storage Systems

Computer hard disk drives (HDD), CD, DVD holds the largest share in the industry

A detailed breakup and analysis of the market based on the application have also been provided in the report. This includes computer hard disk drives (HDD), CD, DVD, hybrid electric vehicles, electric bicycles, heating, ventilating and air conditioners (HVAC), wind turbines, and other applications (transducers and loudspeakers, magnetic separation equipment and sorters, magnetic resonance imaging (MRI), magnetic braking systems, magnetically levitated transportation systems, medicine and health, credit cards and other ID Cards, traveling waves tubes (TWT), advertising and promotional products, magnetic refrigeration system, nanotechnology, military and aerospace, and energy storage systems). According to the report, computer hard disk drives (HDD), CD, DVD accounted for the largest market share.

Computer hard disk drives (HDD), CDs, and DVDs represent the largest market share, as magnets are crucial in their functioning. They are widely used in the actuator of HDDs that position the read/write head over the spinning disks. In optical media, such as CDs and DVDs, magnets are integral to the drives that read and write data. Magnets used in these applications must be precise, reliable, and capable of maintaining their magnetic properties over a long period. Furthermore, the growing demand for reliable data storage systems, such as HDDs, CDs, and DVDs, across various sectors is positively influencing the market growth.

Hybrid electric vehicles (HEVs) use magnets in electric motors and generators that form the core of HEVs. Additionally, the growing need for compact, efficient, and powerful motors in these vehicles is facilitating the demand for high-performance magnets, such as NdFeB. Besides this, the global push towards more environmentally friendly transportation options and the increasing adoption of HEVs are supporting the market growth.

Electric bicycles use magnets in electric motors to provide the necessary propulsion. Additionally, the rising popularity of e-bikes for urban commuting and recreational purposes, driven by a growing awareness of health and environmental benefits, is facilitating the demand for efficient and compact magnet-based motors.

Heating, ventilating, and air conditioning (HVAC) systems use magnets in various components, including compressors, fans, and actuators. Additionally, the surge in demand for energy-efficient and reliable HVAC systems in residential, commercial, and industrial settings, driving the need for high-quality magnets, is favoring the market growth. Moreover, these magnets are instrumental in improving the performance and energy efficiency of HVAC systems, making them more cost-effective and environmentally friendly.

Wind turbines represent a key application segment for magnets, particularly in the context of renewable energy generation. High-performance magnets are used in the generators of wind turbines to convert kinetic wind energy into electrical energy efficiently. These magnets must withstand harsh environmental conditions and maintain their performance over long periods.

Breakup by Country:

- China

- Japan

- USA

- Europe

- Other Regions

China leads the market, accounting for the largest magnet market share

The market research report has also provided a comprehensive analysis of all the major regional markets, which include China, Japan, USA, Europe, and other regions. According to the report, China accounted for the largest market share.

China holds the largest market share due to its expansive manufacturing sector and significant investments in technology and infrastructure. Furthermore, it is a major producer of rare earth elements, which are crucial for high-performance magnets. Additionally, the significant growth in the automotive sector, particularly in electric vehicles, along with its growing renewable energy initiatives in the country, is driving the demand for various types of magnets. Besides this, China's large electronics manufacturing industry, which produces a wide range of consumer electronics and appliances, is further bolstering the market growth.

Japan is known for its technological innovation and high-quality manufacturing standards. The country is a leader in the production of advanced magnets used in various high-tech applications, including electronics, automotive, and robotics. Furthermore, Japanese companies are at the forefront of developing new magnetic materials and technologies, particularly in the realm of miniaturization and energy efficiency.

The magnet market in the USA is driven by its advanced technology sectors and substantial investments in renewable energy and electric vehicles. Furthermore, the country hosts a diverse range of industries that require high-quality magnets, including defense, aerospace, healthcare, and consumer electronics. Additionally, the growing emphasis on sustainable technologies, particularly in wind power and electric transportation, is supporting the market growth.

The magnet market in Europe is characterized by its focus on sustainability, innovation, and quality. European countries are actively involved in the transition to renewable energy sources, particularly wind energy, driving the demand for efficient magnets in wind turbines. Additionally, Europe's strong emphasis on environmental regulations and recycling initiatives, influencing the development of sustainable and recyclable magnetic materials, is contributing to the market growth.

Leading Key Players in the Magnet Industry:

The leading players are engaging in a variety of strategic activities to strengthen their positions and capitalize on the growing market demand. They are heavily investing in research and development (R&D) to innovate and improve the performance of magnetic materials. Additionally, several companies are focusing on making magnets more environmentally sustainable, both in terms of manufacturing processes and recyclability. Besides this, several major players are acquiring smaller companies or forming strategic partnerships to access new technologies and markets, particularly in emerging regions and sectors, such as renewable energy and electric vehicles.

The report provides a comprehensive analysis of the competitive landscape in the global magnet market with detailed profiles of all major companies, including:

- Adams Magnetic Products, LLC

- Arnold Magnetic Technologies

- BGRIMM Technology Group

- Daido Kogyo Co., Ltd.

- DMEGC

- Electron Energy Corporation

- Goudsmit Magnetics

- Lynas Rare Earths Ltd

- Magnequench International, LLC

- Proterial, Ltd

- Shin-Etsu Chemical Co., Ltd.

- TDK Corporation

- Yantai Dongxing Magnetic Materials Inc

Magnet Market News:

- June 2025: The Ministry of Heavy Industries (MHI) and the Department of Atomic Energy (DAE) were prepared to conclude a plan for producing rare earth magnets. The government intended to launch a new initiative with an investment of INR 1,000 Crore aimed at enhancing the domestic production of rare earth magnets, crucial components for sectors like EVs, electronics, and defense.

- April 2025: ITER completed the world's largest and most powerful pulsed magnet system, with key components built by the USA, Russia, Europe, and China. It would function as the electromagnetic core of ITER’s donut-shaped reactor, called a Tokamak.

- February 2025: GE HealthCare introduced Freelium, a groundbreaking sealed magnet system designed to facilitate high-quality magnetic resonance (MR) imaging while using under 1% of helium relative to traditional magnet technology, enhancing both diagnostic precision and sustainability initiatives. Making its debut at the European Congress of Radiology (ECR), Freelium highlighted advancements in GE HealthCare’s proven lightweight intelligent platform magnet technology, with over 2,000 installations globally at 1.5T and 3.0T magnetic fields.

- October 2024: Niron Magnetics opened the world's first factory for high-performance permanent magnets that did not use rare earths in Minneapolis. It represented an important milestone for Niron as it progressed towards mass production of its Clean Earth Magnet® technology and tackled the impending supply and demand shortfall for permanent magnets.

Magnet Market Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Billion USD, 000’ Metric Tons |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Magnet Types Covered | Ferrite, Neodymium Iron Boron (NdFeB), Aluminium Nickel Cobalt (AlNiCo), Samarium Cobalt (SmCo) |

| Applications Covered |

|

| Countries Covered | China, Japan, USA, Europe, Other Regions |

| Companies Covered | Adams Magnetic Products, LLC, Arnold Magnetic Technologies, BGRIMM Technology Group, Daido Kogyo Co., Ltd., DMEGC, Electron Energy Corporation, Goudsmit Magnetics, Lynas Rare Earths Ltd, Magnequench International, LLC, Proterial, Ltd, Shin-Etsu Chemical Co., Ltd., TDK Corporation, Yantai Dongxing Magnetic Materials Inc, etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the magnet market from 2019-2033.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the global magnet market.

- The study maps the leading, as well as the fastest-growing, regional markets.

- Porter's five forces analysis assists stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the magnet industry and its attractiveness.

- The competitive landscape allows stakeholders to understand their competitive environment and provides insight into the current positions of key players in the market.

Key Questions Answered in This Report

The global magnet market was valued at USD 41.75 Billion in 2024.

We expect the global magnet market to exhibit a CAGR of 3.82% during 2025-2033.

The growing demand for electric vehicles, along with the increasing application of magnet in the automotive sector for auto-clutch, electric braking, and throttle and gearbox actuation, is currently catalyzing the global magnet market.

The sudden outbreak of the COVID-19 pandemic has led to the rising demand for ventilators in treating patients with respiratory failures, resulting in growing utilization of magnets as they an essential component for medical equipment.

Based on the magnet type, the global magnet market can be segmented into ferrite, Neodymium Iron Boron (NdFeB), Aluminium Nickel Cobalt (AlNiCo), and Samarium Cobalt (SmCo). Currently, Neodymium Iron Boron (NdFeB) holds the majority of the total market share.

Based on the application, the global magnet market can be categorized into computer Hard Disk Drives (HDD), CD, DVD, hybrid electric vehicles, electric bicycles, Heating, Ventilating and Air Conditioners (HVAC), wind turbines, and other applications. Among these, computer Hard Disk Drives (HDD), CD, DVD currently account for the largest market share.

On a regional level, the market has been classified into China, Japan, USA, Europe, and other regions, where China currently dominates the global market.

Some of the major players in the global magnet market include Adams Magnetic Products, LLC, Arnold Magnetic Technologies, BGRIMM Technology Group, Daido Kogyo Co., Ltd., DMEGC, Electron Energy Corporation, Goudsmit Magnetics, Lynas Rare Earths Ltd, Magnequench International, LLC, Proterial, Ltd, Shin-Etsu Chemical Co., Ltd., TDK Corporation, Yantai Dongxing Magnetic Materials Inc, etc.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)