Shape Memory Alloys Market Size, Share, Trends and Forecast by Alloy Type, End-Use Industry, Functionality Type, Application, and Region, 2025-2033

Shape Memory Alloys Market Size and Share:

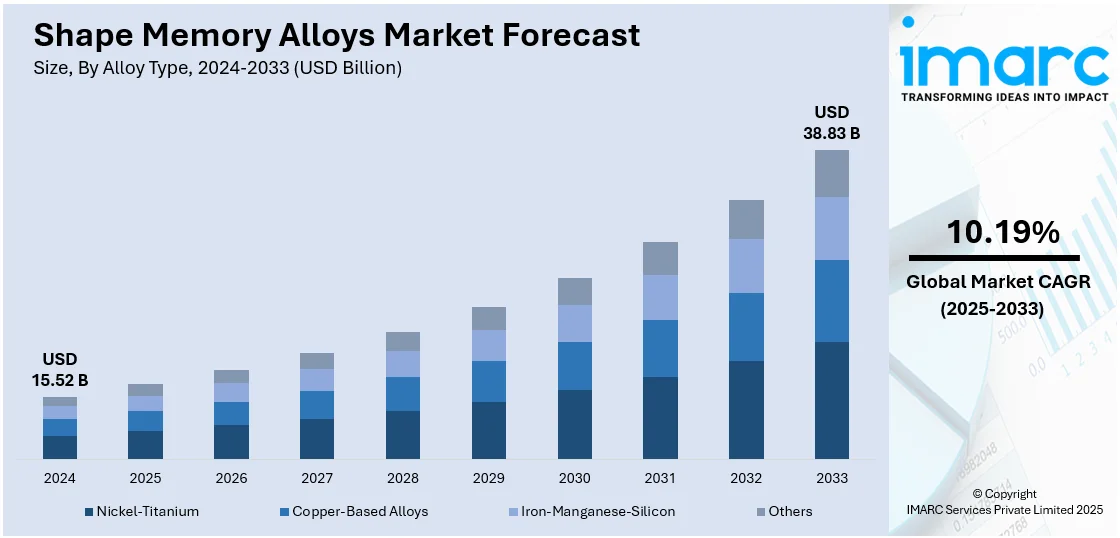

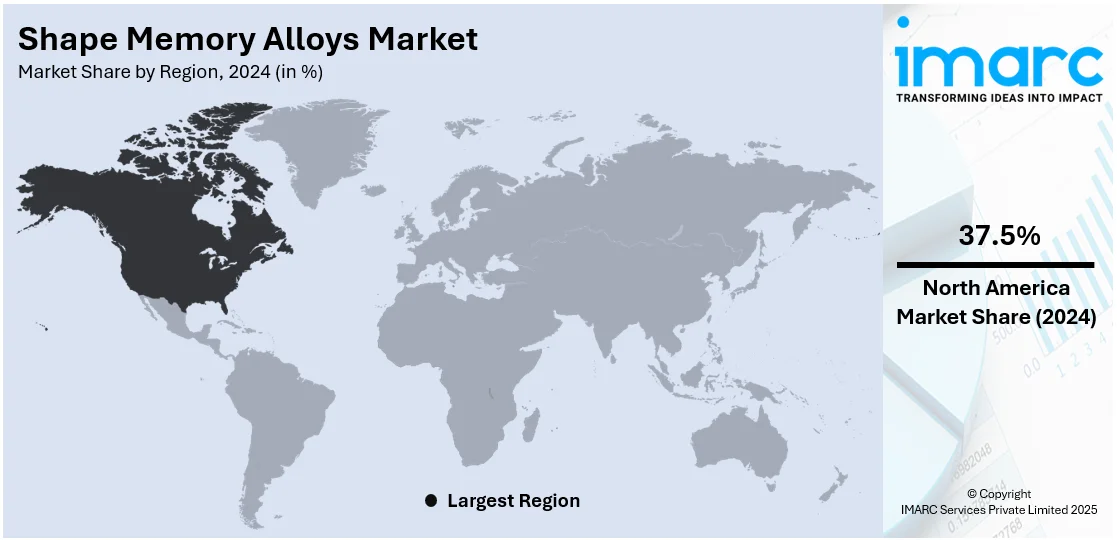

The global shape memory alloys market size was valued at USD 15.52 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 38.83 Billion by 2033, exhibiting a CAGR of 10.19% from 2025-2033. North America currently dominates the market, holding a market share of 37.5% in 2024. The growing demand for consumer electronic items is encouraging manufacturers to look for compact, efficient, and durable materials like shape memory alloys to enhance product functionality. Besides this, rising vehicle production and increasing construction activities are contributing to the expansion of the shape memory alloys market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024

|

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

|

Market Size in 2024

|

USD 15.52 Billion |

|

Market Forecast in 2033

|

USD 38.83 Billion |

| Market Growth Rate 2025-2033 | 10.19% |

The market is experiencing growth, as industries are recognizing the unique properties of shape memory alloys like super elasticity and shape recovery. Shape memory alloys are in high demand due to their utilization in stents, guidewires, and surgical equipment. Aerospace firms employ them in actuators and vibration dampers to improve performance and reduce weight. They are being used in the car industry for smart safety features and comfort systems. Shape memory alloys are being adopted in the electronics and robotics industries to create compact and responsive components. Apart from this, research initiatives aim to improve the strength and flexibility of shape memory alloys.

The United States has emerged as a major region in the shape memory alloys market owing to many factors. The rising demand across the medical, aerospace, automotive, and electronics industries is fueling the shape memory alloys market growth. Medical device manufacturers are using shape memory alloys in stents, dental wires, and surgical tools because of their biocompatibility and flexibility. Aerospace companies are adopting shape memory alloys for actuators and vibration dampers to enhance performance and reduce weight. Additionally, electronics and robotics companies are applying shape memory alloys in compact devices that require precise movement. Apart from this, government support for high-tech manufacturing and defense is stimulating the market growth. Rising smart home demand is encouraging the utilization of shape memory alloys since they enable innovative, efficient, and durable solutions in home automation systems. As per industry reports, by 2024, the total smart homes in the United States were projected to hit 69.91 Million, expanding to 93.59 Million by 2027.

Shape Memory Alloys Market Trends:

Increasing vehicle production

Rising vehicle production is positively influencing the market. In 2024, worldwide car sales reached 74.6 Million units, showcasing a 2.5% increase from 2023, according to ACEA. Shape memory alloys, especially nickel-titanium, offer excellent properties like high strength, flexibility, and corrosion resistance, making them ideal for automotive applications. These alloys are used in components, such as actuators, sensors, and adaptive systems, improving vehicle performance and safety. They help optimize features like adjustable seats, mirrors, and airbags. Their ability to respond to temperature changes and perform mechanical movements without external power makes them highly suitable for modern energy-efficient vehicles. As the demand for electric and autonomous vehicles is growing, the need for advanced materials, such as shape memory alloys, is increasing.

Rising need for consumer electronics

Increasing demand for consumer electronics is offering a favorable shape memory alloys market outlook. Shape memory alloys, especially nickel-titanium, are ideal for miniaturized devices due to their ability to change shape in response to temperature or electrical signals. They are used in various electronic components, such as microactuators, switches, and connectors, enabling more precise and reliable operations. As the consumer electronics industry is evolving, shape memory alloys aid in improving device performance, reducing size, and increasing longevity. Their use in mobile phones, laptops, wearables, and other gadgets allows smarter and more efficient designs. With the growing need for advanced and innovative electronic devices, the market for shape memory alloys continues to expand, supporting high-performance applications in the industry. According to Invest Up, India is set to reach a USD 1 Trillion digital economy by FY26, with its electronics sector estimated at USD 155 Billion, 65% of which originates from local production.

Growing construction activities

Increasing construction activities are propelling the market growth. As per industry reports, nominal construction expenditures were anticipated to hit USD 14.7 Trillion in 2024 and USD 15.6 Trillion by 2025, indicating a 3.2% and 6.4% rise year-over-year, respectively. Shape memory alloys offer unique properties like super-elasticity and corrosion resistance, making them ideal for applications in buildings, bridges, and infrastructure. These alloys are used in seismic and structural reinforcement systems, allowing buildings to respond to stress and vibrations during earthquakes and extreme weather conditions. Additionally, shape memory alloys are employed in smart structures, where they enable self-healing and adaptive features to improve durability and safety. As urbanization activities are accelerating and construction projects are becoming more complex, the need for high-performance materials like shape memory alloys is increasing. As per the shape memory alloys market report, their ability to perform under dynamic conditions and enhance structural integrity aids in fueling the growth of the market.

Shape Memory Alloys Industry Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the global shape memory alloys market, along with forecast at the global, regional, and country levels from 2025-2033. The market has been categorized based on alloy type, end-use industry, functionality type, and application.

Analysis by Alloy Type:

- Nickel-Titanium

- Copper-Based Alloys

- Iron-Manganese-Silicon

- Others

Nickel-titanium held 71.2% of the market share in 2024. It offers excellent shape memory effect, super elasticity, and corrosion resistance. This alloy returns to its original shape after deformation, making it ideal for various precision applications. In the medical field, nickel-titanium is widely utilized in stents, guidewires, and dental braces due to its biocompatibility and flexibility. It also performs well in harsh environments, making it suitable for aerospace and industrial uses. The alloy handles repeated stress without losing function, which is important for long-term performance. Its thermal and mechanical properties allow controlled movements, attracting demand in actuators and robotics. Manufacturers prefer it for its durability and reliability, especially in critical sectors. Its high fatigue resistance and low maintenance needs reduce long-term costs. These features, along with increasing innovations in medical and smart systems, are supporting its dominance. As per the shape memory alloys market forecast, with industries seeking efficient and responsive materials, nickel-titanium is set to gain preference in the market.

Analysis by End-Use Industry:

- Biomedical

- Aerospace & Defense

- Automotive

- Consumer Electronics & Home Appliances

- Others

Biomedical accounts for 43.7% of the market share. It holds dominance because of the alloy’s unique properties that suit medical applications. Shape memory alloys, especially nickel-titanium, offer excellent biocompatibility, corrosion resistance, and elasticity, which make them ideal for implants and surgical tools. They are widely used in stents, dental wires, orthopedic implants, and minimally invasive surgical devices. These materials adapt to body conditions and return to their original shape after deformation, which helps improve patient comfort and recovery. The demand for advanced medical devices continues to rise due to increasing surgeries, aging populations, and chronic health conditions. Shape memory alloys also reduce complications and support faster healing, which boosts their utilization in modern healthcare. Their flexibility and responsiveness allow innovations in robotic surgery and micro devices. As healthcare technologies are evolving, the biomedical sector relies more on shape memory alloys for reliable and high-performance solutions, driving its lead position in the market.

Analysis by Functionality Type:

- Super-elasticity (or Pseudoelasticity)

- Constrained Recovery

- Free Recovery

- Others

Super-elasticity (or pseudoelasticity) allows the material to undergo large strains and return to its original shape upon unloading, without the need for temperature changes. It is commonly used in applications that require mechanical flexibility and high strength, such as in medical devices like stents, guidewires, and orthodontic appliances. Super-elastic alloys are particularly beneficial in environments that involve cyclic loads, making them ideal for dynamic and high-stress applications.

Constrained recovery refers to the material’s ability to recover its original shape when constrained, typically under high pressure and force. This characteristic is vital in applications where the material needs to perform specific movements or deformations in a controlled environment. Constrained recovery alloys are widely used in actuators, such as in aerospace and robotics, where precise control of movements is essential. Their ability to generate force and act as a mechanical actuator makes them highly valued in various industries requiring accurate motion control.

Free recovery refers to the ability of shape memory alloys to return to their original shape when heated, without external constraints. This property is particularly useful in applications where the material needs to revert to a predefined shape after being subjected to deformation. Free recovery alloys are often employed in applications like self-healing materials, switches, and coupling devices. Their ability to recover without external force makes them ideal for creating components that can react automatically to changes in temperature, ensuring functionality even in dynamic environments.

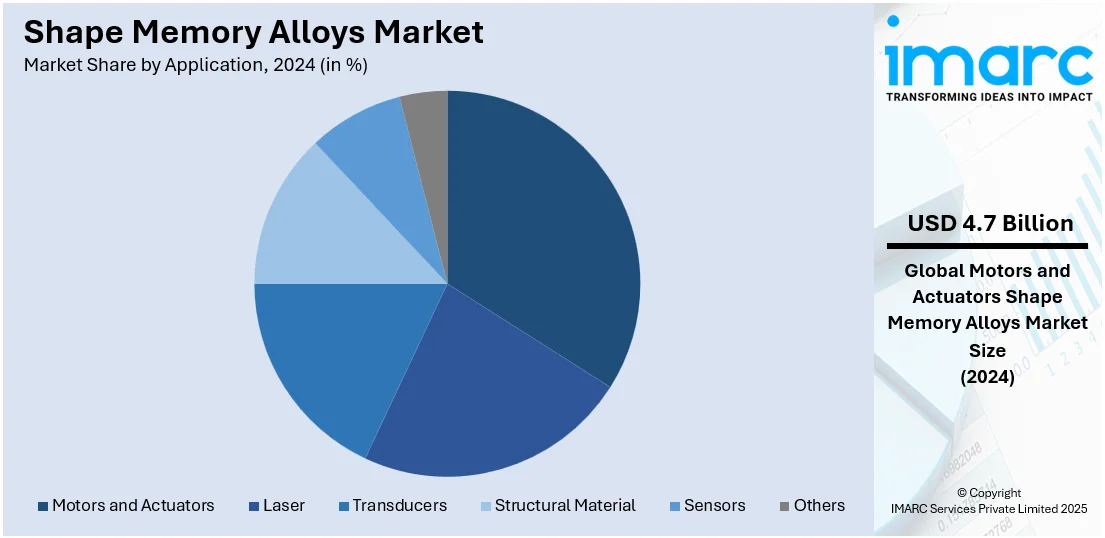

Analysis by Application:

- Laser

- Motors and Actuators

- Transducers

- Structural Material

- Sensors

- Others

Motors and actuators hold 30.3% of the market share. They take full advantage of the unique mechanical properties of shape memory alloys. These alloys, especially nickel-titanium, change shape in response to temperature and electrical signals, making them ideal for compact and efficient motion control systems. Shape memory alloy-based motors and actuators are widely used in robotics, aerospace, automotive systems, and industrial automation, where precise movement and miniaturization are essential. In aerospace, they control airflow and movable parts without adding much weight. In automotive systems, they support features like adaptive mirrors, seat adjustments, and airflow control. Their ability to generate motion without complex mechanical systems makes them attractive for next-generation devices. As industries are promoting smarter and more compact solutions, the demand for shape memory alloy-based motors and actuators continues to rise. This strong requirement across multiple sectors helps motors and actuators lead the overall application segment.

Regional Analysis:

- North America

- United States

- Canada

- Asia-Pacific

- China

- Japan

- India

- South Korea

- Australia

- Indonesia

- Others

- Europe

- Germany

- France

- United Kingdom

- Italy

- Spain

- Russia

- Others

- Latin America

- Brazil

- Mexico

- Argentina

- Colombia

- Chile

- Peru

- Others

- Middle East and Africa

- Turkey

- Saudi Arabia

- Iran

- United Arab Emirates

- Others

North America, accounting for a share of 37.5%, enjoys the leading position in the market. The region is recognized due to its strong presence of key industries like aerospace, automotive, healthcare, and electronics. The region has a high demand for advanced materials that offer flexibility, precision, and durability, which is encouraging the use of shape memory alloys. The medical sector in North America is adopting shape memory alloys in devices, such as stents, surgical tools, and orthodontic wires. Aerospace and defense companies are employing shape memory alloys for actuators and adaptive structures, supported by government investments. The thriving automotive industry is also contributing by integrating shape memory alloys into safety and comfort systems. According to the IMARC Group, the North America automotive market size reached USD 1,163.77 Billion in 2024. In addition, the region hosts leading shape memory alloy manufacturers and research institutions that promote continuous innovations. A well-developed industrial base, strong research and development (R&D) infrastructure, and skilled workforce are facilitating the rapid development and deployment of shape memory alloy-based solutions.

Key Regional Takeaways:

United States Shape Memory Alloys Market Analysis

The United States holds 86.80% of the market share in North America. The market is demonstrating robust growth, driven by advancements in medical technology, consumer electronics, and aerospace applications. For example, Oklahoma Commerce reported that the United States’ aerospace & defense industry attracted USD 146.6 Million in new capital investment in 2024, highlighting the growing industrial need for advanced materials like shape memory alloys. Increasing investments in R&D and the integration of shape memory alloys into minimally invasive devices and high-performance components have significantly enhanced market prospects. The demand is further driven by the adoption of smart materials in high-precision environments, where performance and efficiency are critical. The rise in automation and evolving manufacturing standards have also played a pivotal role in expanding the application scope of shape memory alloys across sectors. Technological innovations, combined with a focus on reducing maintenance and improving system responsiveness, are contributing to the market growth. Favorable regulatory frameworks and the shift towards lightweight and energy-efficient materials are further shaping growth trends. The market is benefiting from a mature infrastructure that supports advancements and rapid product development.

Europe Shape Memory Alloys Market Analysis

The shape memory alloys market in Europe is marked by steady expansion due to heightened interest in adaptive materials across industrial and biomedical sectors. The growing demand for precision-based components is supporting the wider adoption of shape memory alloys, particularly in responsive systems and compact devices. Enhanced focus on material performance and lifecycle efficiency has encouraged the integration of shape memory alloys in critical applications requiring durability and adaptability. The biomedical segment plays a key role in this growth, supported by the region’s robust healthcare innovation ecosystem. According to MedTech Europe, in 2024, the European medical technology industry comprised over 37,000 companies and delivered over 2 Million products, services, and solutions, including cancer screening tests, pacemakers, and glucose monitors, which benefited from the properties of shape memory alloys. The market for sustainable metal additives, including shape memory alloys, is gaining momentum due to regulatory alignment, sustainable manufacturing practices, technological advancements, and the region's strong engineering and materials science capabilities, focusing on lightweight design and energy optimization.

Asia-Pacific Shape Memory Alloys Market Analysis

In the Asia-Pacific region, the market is witnessing rapid expansion, driven by industrial modernization and technological advancements across diverse sectors. Strong manufacturing capabilities and the growing demand for high-efficiency materials have positioned shape memory alloys as integral to innovations in various applications. Increasing investments in infrastructure and product development are supporting market penetration in areas where precision and flexibility are critical. The region is benefiting from dynamic industrial growth and the ongoing integration of smart materials in consumer electronics. According to Invest India, household electronics usage in the country is projected to reach USD 270 Billion by 2030, highlighting the rising demand for advanced materials like shape memory alloys in compact and high-performance devices. Research initiatives and academic collaborations are further contributing to new advancements in shape memory alloys-based systems. The market is further bolstered by the increasing focus on responsive components in compact and multifunctional designs, particularly within fast-growing economies.

Latin America Shape Memory Alloys Market Analysis

The Latin America market is experiencing growth due to increasing awareness and applications in industrial and medical fields, with advanced materials being adopted for functional components and responsive systems, offering advantages in compact and efficient materials. Educational and research institutions are playing a role in expanding technical knowledge and encouraging innovations. Moreover, rising automotive industrial output is enhancing the scope for shape memory alloy integration. Portal Lubes reported that Brazil ranked eighth among the world’s largest vehicle-producing countries in 2024, manufacturing 2.55 Million vehicles, reflecting a 9.7% increase from 2023. This industrial momentum is highlighting the growing demand for adaptive materials that enhance performance and design efficiency.

Middle East and Africa Shape Memory Alloys Market Analysis

In the Middle East and Africa region, the market is expanding owing to advanced material technologies and interest in innovative solutions for smart and adaptive systems. The demand for efficient and resilient materials is promoting the exploration of shape memory alloys in emerging sectors. A significant boost is coming from regional initiatives aimed at strengthening local industries. For instance, Saudi Arabia's General Authority for Military Industries signed 53 industrial cooperation programs worth USD 9.32 Billion with local and international companies, including USD 3.46 Billion in purchase orders for domestic firms. High-performance materials, including shape memory alloys, are being used in advanced manufacturing and defense systems due to educational initiatives, market expansion, and regional acceptance.

Competitive Landscape:

Key players are working to develop advanced solutions to meet the high demand. These companies are investing in R&D activities to improve the performance, durability, and versatility of shape memory alloys. They are collaborating with medical, aerospace, and automotive industries to create specialized applications, which is driving the demand for shape memory alloys. Key players also focus on expanding their manufacturing capabilities to meet evolving requirements. They introduce advanced alloy compositions and processing techniques to enhance functionality. By maintaining strong distribution networks and worldwide presence, they ensure widespread availability of shape memory alloy products. These companies also work closely with academic institutions and research labs to stay ahead in material science. Their efforts in promoting awareness and educating industries about the benefits of shape memory alloys are further accelerating market adoption. For instance, in January 2025, Waters Corporation unveiled the TGA Smart-Seal™ Pans, a solution for evaluating atmosphere-sensitive substances using standard benchtop thermogravimetric analyzers (TGA). The pans, which utilized a temperature-responsive shape memory alloy, self-opened at 55°C, removing the necessity for gloveboxes.

The report provides a comprehensive analysis of the competitive landscape in the shape memory alloys market with detailed profiles of all major companies, including:

- Allegheny Technologies

- DYNALLOY, Inc.

- EUROFLEX GmbH

- Fort Wayne Metals

- G.RAU GmbH & Co. KG

- Metalwerks, Inc.

- Nippon Steel Group

- SAES Getters S.p.A.

- Furukawa Electric Co., Ltd.

- TiNi Aerospace, Inc.

- Ultimate NiTi Technologies

Latest News and Developments:

- April 2025: Huawei announced the release of its FreeArc open-ear TWS earbuds in the Philippines. Initially revealed in Malaysia, the earbuds designed for sports included IP57 water resistance, high-quality construction, 0.7mm shape memory alloy, and an ergonomic shape featuring a 17x12mm driver, dynamic bass, along with an adaptive equal-loudness algorithm for improved sound quality.

- February 2025: Huawei introduced the HUAWEI Mate XT, a market-ready tri-fold smartphone. The Mate XT featured an incredibly resilient screen and incorporated shape memory alloy into its construction.

- January 2025: Hyundai Motor and Kia presented their open innovation hubs, ZER01NE and CRADLE, collaborating with 10 international startups. ZER01NE concentrated on promoting startups that leveraged advanced materials, such as shape memory alloys, for creative solutions.

Shape Memory Alloys Market Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Billion USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Alloy Types Covered | Nickel-Titanium, Copper-Based Alloys, Iron-Manganese-Silicon, Others |

| End-Use Industries Covered | Biomedical, Aerospace & Defense, Automotive, Consumer Electronics & Home Appliances, Others |

| Functionality Types Covered | Super-elasticity (or Pseudoelasticity), Constrained Recovery, Free Recovery, Others |

| Applications Covered | Laser, Motors and Actuators, Transducers, Structural Material, Sensors, Others |

| Regions Covered | North America, Asia-Pacific, Europe, Latin America, Middle East and Africa |

| Countries Covered | United States, Canada, China, Japan, India, South Korea, Australia, Indonesia, Germany, France, United Kingdom, Italy, Spain, Russia, Brazil, Mexico, Argentina, Colombia, Chile, Peru, Turkey, Saudi Arabia, Iran, United Arab Emirates, Others |

| Companies Covered | Allegheny Technologies, DYNALLOY, Inc., EUROFLEX GmbH, Fort Wayne Metals, G.RAU GmbH & Co. KG, Metalwerks, Inc., Nippon Steel Group, SAES Getters S.p.A., Furukawa Electric Co., Ltd., TiNi Aerospace, Inc., Ultimate NiTi Technologies, etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the shape memory alloys market from 2019-2033.

- The research study provides the latest information on the market drivers, challenges, and opportunities in the global shape memory alloys market.

- The study maps the leading, as well as the fastest-growing, regional markets. It further enables stakeholders to identify the key country-level markets within each region.

- Porter's Five Forces analysis assists stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the shape memory alloys industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

The shape memory alloys market was valued at USD 15.52 Billion in 2024.

The shape memory alloys market is projected to exhibit a CAGR of 10.19% during 2025-2033, reaching a value of USD 38.83 Billion by 2033.

The medical sector is employing shape memory alloys in devices like stents, guidewires, and orthopedic implants. Besides this, aerospace and automotive industries are adopting these materials for actuators, vibration control, and safety systems, appreciating their lightweight nature and reliability. Moreover, the growing awareness about advanced materials and increasing investments in smart technologies are positively influencing the market.

North America currently dominates the shape memory alloys market, accounting for a share of 37.5% in 2024, driven by strong industrial demand, advanced research facilities, and a high adoption rate in sectors like healthcare, aerospace, and automotive. Investments by key players in innovation centers are also supporting the market growth in the region.

Some of the major players in the shape memory alloys market include Allegheny Technologies, DYNALLOY, Inc., EUROFLEX GmbH, Fort Wayne Metals, G.RAU GmbH & Co. KG, Metalwerks, Inc., Nippon Steel Group, SAES Getters S.p.A., Furukawa Electric Co., Ltd., TiNi Aerospace, Inc., Ultimate NiTi Technologies, etc.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)