Bagasse Based Kraft Paper Cost Model: Efficient Production and Market Trends

What is Bagasse Based Kraft Paper?

Bagasse kraft paper is a green packaging material made from bagasse, the fibrous byproduct that is left when juice is extracted from sugarcane. Kraft paper is generally produced traditionally using wood pulp via the sulfate process, but bagasse offers a sustainable, non-wood source used in promoting green manufacturing and less reliance on forest resources.

Key Applications Across Industries:

Bagasse fibers have high cellulose, moderate fiber length, and good bonding properties, making them ideal for manufacturing strong and long-lasting kraft paper. Production includes bagasse collection from sugar mills, purification to eliminate impurities, and processing into pulp either by chemical or mechanical pulping. The pulp can either be bleached or retained in its natural state, depending on the grade of paper to be produced. Following the formation and pressing, the sheets are dried and rolled into kraft rolls. Bagasse kraft paper has good tensile strength, printability, and flexibility and is well suited for packaging materials like paper bags, wrapping paper, corrugated boxes, and liners. Its biodegradable and compostable properties enable it to break down without leaving behind microplastics or toxic residues, which is in accordance with the global trend towards circular economy practices. In addition, using bagasse as a raw material gives sugar industries another source of revenue and reduces burning of agricultural waste, which pollutes the environment. In general, bagasse-kraft paper is a combination of waste valorization, resource efficiency, and environmentally friendly industrial practices, with a practical alternative to wood-kraft paper in packaging and industrial use such as bags, wrapping papers, and banknotes.

What the Expert Says: Market Overview & Growth Drivers

The global kraft paper market reached a value of USD 18.6 Billion in 2024. According to IMARC Group, the market is projected to reach USD 28.8 Billion by 2033, at a projected CAGR of 5.65% during 2025-2033. The demand for bagasse-based kraft paper at the global level is being fueled by increasing environment consciousness, regulatory favor to sustainable packaging, and the imperative towards substitute renewable raw material solutions.

Among the most consequential drivers is the global movement to curtail deforestation and carbon footprint of conventional wood pulp-based paper making. Bagasse, as an agricultural residue, offers a sustainable and available feedstock, lessening the burden on forest resources and helping the world move towards bio-based materials. Increasing regulations on single-use plastics and non-degradable packaging, especially in food, retail, and e-commerce industries, are also driving demand for biodegradable and recyclable paper products. Moreover, most multinational retailers and brands are embracing cleaner supply chain strategies that support the use of compostable and biodegradable packaging materials, further favoring the use of bagasse-based kraft paper. Advances in pulping and paper-forming technologies have enhanced the strength, smoothness, and print quality of bagasse kraft paper to be on par with those of traditional wood-based grades. Financial considerations too come into play in sugarcane-producing nations like India, Brazil, and Thailand, ready availability of bagasse decreases raw material costs and promotes integrated production models around sugar mills. In addition, demand from consumers for environmentally friendly packaging across developed markets like Europe and North America, along with the growing popularity of sustainability product labels and certifications, is driving worldwide adoption. Basically, the kraft paper market from bagasse is growing on the back of a mix of policy action, business innovation, and growing convergence between environmental sustainability and commercial packaging requirements.

Case Study on Cost Model of Bagasse Based Kraft Paper Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale bagasse based kraft paper manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed bagasse based kraft paper manufacturing plant in India. This plant is designed to manufacture 15,000 tons of bagasse based kraft paper annually.

Manufacturing Process: The process of manufacturing bagasse-based kraft paper entails transforming sugarcane waste into robust, environmentally friendly paper via a set of pulping, refining, and shaping operations intended to preserve strength and quality while reducing wastage. The cycle starts with the collection of bagasse from sugar mills, where fibrous residue is produced after extracting juice. The raw bagasse is cleaned and depithed initially to wash out dust, short pith fibers, and impurities because excessive pith can undermine the paper structure. The bagasse is thereafter treated through chemical pulping, more commonly either the kraft or soda process, whereby it is cooked in a digester with caustic soda or sodium carbonate at high pressure and heat. This ruptures lignin and delignifies the cellulose fibers. The pulp so produced is washed, screened, and bleached to eliminate any remaining chemicals and attain the necessary fiber consistency. Depending on the grade of kraft paper to be obtained, the pulp can either be bleached with eco-friendly bleaching chemicals to yield lighter colors or not bleached at all to give natural brown kraft paper. The purified pulp is next pumped into a paper machine, where water is added and the pulp spreads on to a travelling wire mesh in an even layer to create a continuous sheet. The sheet is sent through pressing and drying units, which take water out and stick fibers together by heat and pressure, giving strength and smoothness. Lastly, the dried paper is calendered, cut, and rolled up. Wastewater is treated and re-circulated, and spent pulping liquors are recovered by chemical recovery systems, which makes the process resource-conserving and environmentally friendly.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

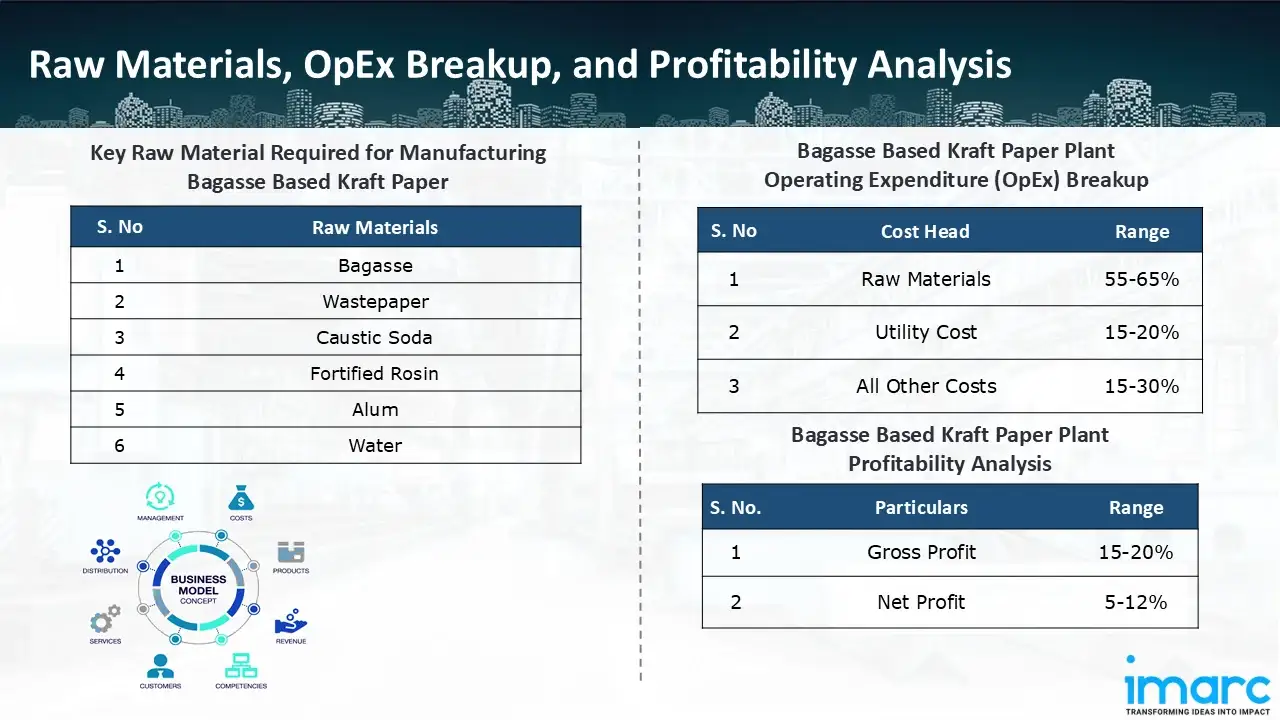

The basic raw materials required for bagasse based kraft paper manufacturing include:

- Bagasse

- Wastepaper

- Caustic Soda

- Fortified Rosin

- Alum

- Water

Machineries Required:

- Bagasse Receiving & Storage Silos

- Bagasse Washers / Conveyors

- Depithers

- Digesters / Kraft Digesters

- Chemical Mixing Units

- Pulp Washers

- Screening Machines

- Bleaching Towers / Reactors

- Mixing & Agitation Tanks

- Pulp Washers After Bleaching

- Refiners / Beaters

- Screening / Cleaning Units

- Headbox/Feeding Unit

- Forming Section

- Press Section

- Dryer Section

- Calender Stack

- Reel / Winder

- Slitter / Rewinder

- Sheeters

- Inspection Tables / Testers

- Evaporators

- Recovery Boiler

- Causticizer / Lime Kiln

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in a bagasse based kraft paper manufacturing plant ranges between 55-65%, utility cost ranges between 15% to 20%, and all other costs ranges between 15-30% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 15-20%, and net profit lie between the range of 5-12% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the bagasse based kraft paper manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 15,000 tons of bagasse based kraft paper annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In April 2025, the Indian Paper Manufacturers Association (IPMA) called for government action to shield domestic producers from an increase in low-cost paper imports. The US's tariffs on important Asian exporters are raising concerns because they may cause surplus inventories to be diverted to India.

- In January 2025, Tamil Nadu Newsprint & Papers Limited (TNPL) set a capital investment plan totalling INR 600-650 crore for FY25 and FY26. TNPL has an annual manufacturing capacity of 4,40,000 tonnes of writing and printing paper and 2,00,000 tonnes of speciality boards.

- In October 2024, Lintec expanded its line of water-repellent papers that prevent rainfall penetration to include an unbleached and uncoloured kind of Kraft paper. Lintec mainly suggested it for use in the logistics industry, and it is very appropriate for processing into carrier bags and envelopes.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104