Biogas Manufacturing Cost Model: A Complete Overview of Production Expenses

What is Biogas?

Biogas is a renewable energy form generated by the anaerobic fermentation of organic matter including agricultural residues, animal waste, municipal solid waste, sewage sludge, and food waste. Microorganisms in the absence of oxygen break down organic substances in the process and produce a gaseous mixture of mainly methane (CH4) and carbon dioxide (CO2), with traces of hydrogen sulfide (H2S) and water vapor.

Key Applications Across Industries:

The methane content makes biogas a great alternative to natural gas in power, heating, and as a fuel for transportation as biomethane. The versatility in feedstock of biogas presents it as a beneficial answer to waste management and support for a circular economy by turning waste into energy as well as organic fertilizer. The process of production can be executed at various scales, from rural small-scale household digesters to industrial-scale facilities. In addition to this, raw biogas being upgraded by purification technologies can be injected into natural gas grids or compressed as CBG (Compressed Biomethane Gas). Biogas is consistent with reducing the greenhouse gas emissions and fossil fuel dependency, thus helping energy transition according to sustainable goals. Growing interest in decentralized energy systems, rural electrification, and recycling of organic waste further elevates its importance in the renewable energy sector across the world.

What the Expert Says: Market Overview & Growth Drivers

The global biogas market reached a value of USD 74.37 Billion in 2024. According to IMARC Group, the market is projected to reach USD 106.03 Billion by 2033, at a projected CAGR of 3.82% during 2025-2033. The biogas market all over the world is shaped by a mix of environmental, economic, and policy motivations favoring renewable energy usage and green waste management.

One of the key drivers for growth is the growing demand for clean and green energy solutions as the world becomes more concerned about climate change and greenhouse gas emissions. Biogas provides a carbon-free alternative to fossil fuels and is therefore the key to meeting national and corporate net-zero ambitions. Encouraging government policies such as subsidies, feed-in tariffs, and renewable energy obligations in markets like the EU, North America, and Asia-Pacific are driving investment in biogas facilities. The increasing emphasis on circular economy processes also drives the market, as biogas facilities make possible the transformation of organic waste into valuable energy and nutrient-rich digestate for farming. Industrialization and urbanization at a fast pace have fueled waste generation, and nations have begun adopting biogas as a green waste management option. In addition, technological improvements in biogas upgrading to biomethane have broadened its application for transportation and feeding into gas grids, which enhances its commercial viability. In developing countries, biogas is a cheap means of rural electrification and cooking, minimizing wood and fossil fuel dependence. Moreover, worldwide energy crises and price volatile oil prices have cemented the relevance of indigenous renewable energy forms such as biogas in ensuring energy security. In total, the combination of renewable energy policies, waste-to-energy projects, and sustainable development goals continues to ensure remarkable growth and investment opportunities in the international biogas industry.

Case Study on Cost Model of Biogas Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale biogas manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed biogas manufacturing plant in India. This plant is designed to produce 300 tons of biogas per day.

Manufacturing Process: The production process of biogas includes the anaerobic digestion of organic waste, where microorganisms digest biodegradable material in the absence of oxygen to generate biogas and digestate. The process commences with feedstock collection and preparation, which involves collecting organic waste like agricultural residues, animal dung, food wastes, or sewage sludge. These materials tend to be shredded or blended with water to form a homogeneous slurry ideal for digestion. The pre-treated feedstock is then pumped into an anaerobic digester, an airtight vessel that supports precise temperature and pressure conditions favorable for microbial growth. The anaerobic digestion process takes place in four main stages including hydrolysis, acidogenesis, acetogenesis, and methanogenesis. During hydrolysis, organic complex molecules such as carbohydrates, lipids, and proteins are hydrolyzed into their simpler counterparts like sugars, fatty acids, and amino acids. In acidogenesis, these molecules are transformed into volatile fatty acids, carbon dioxide, hydrogen, and ammonia. Acetogenesis then processes these intermediates further into acetic acid, which is eventually transformed into methane (CH4) and carbon dioxide (CO2) by methanogenic bacteria, the main constituents of biogas. The generated biogas is harvested at the top of the digester and generally purified or upgraded to eliminate impurities such as hydrogen sulfide, water, and carbon dioxide to produce higher-grade biomethane that can be used for energy production or injected into gas networks. The byproduct that remains, which is referred to as digestate, is rich in nutrients and utilizable as an organic fertilizer. This combined process not only produces renewable power but also offers a clean solution to waste disposal and soil fertilization.

Get a Tailored Feasibility Report for Your Project Request Sample

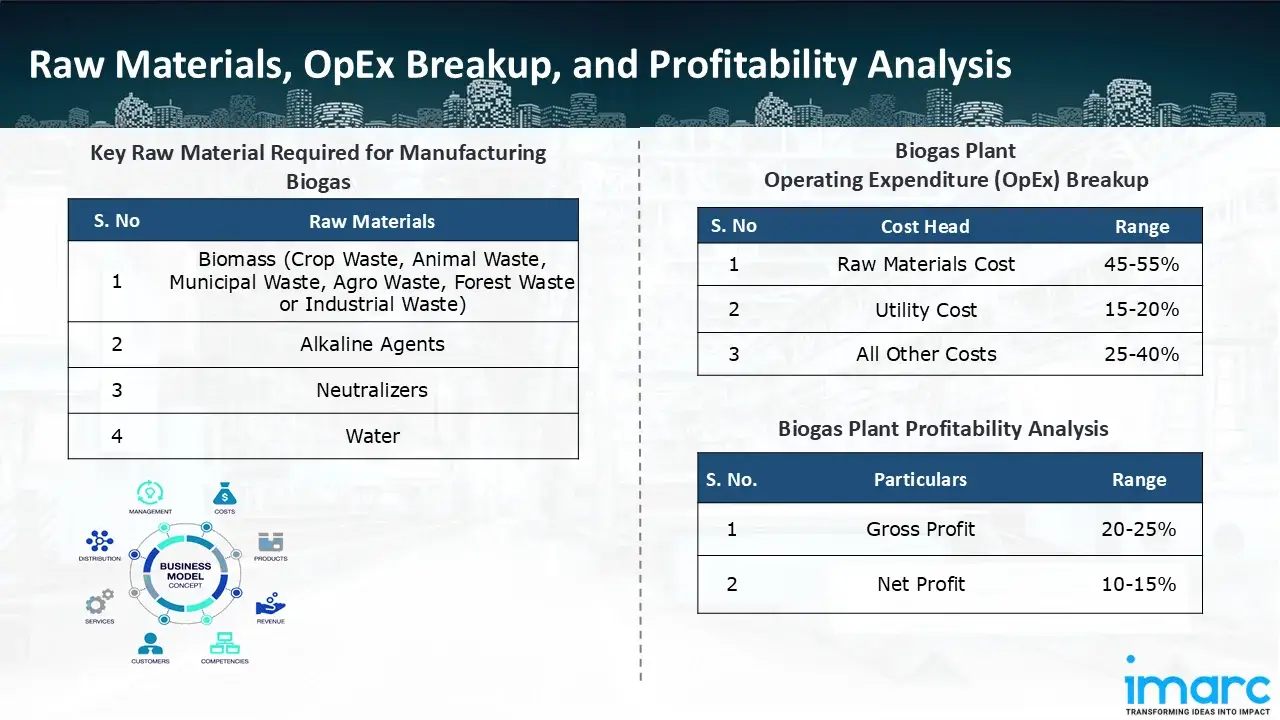

Raw Material Required:

The basic raw materials required for biogas manufacturing include:

- Biomass (Crop Waste, Animal Waste, Municipal Waste, Agro Waste, Forest Waste or Industrial Waste)

- Alkaline Agents

- Neutralizers

- Water

Machineries Required:

- Feedstock Silos

- Shredder/ Grinder/Chopper

- Mixer

- Homogenizer

- Conveyor/Pump

- Anaerobic Digestor

- Agitators and Pumps

- Cooling Unit

- Gas Dehumidifier

- Reheater

- Boiler

- RO Plant

- Scrubber

- Compressor

- Membrane Based Purification System

- THT Gas Injector

- High Pressure Compressor

- Overflow Tank

- Storage Pressure Vessel

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in a biogas manufacturing plant ranges between 45-55%, utility cost ranges between 15% to 20%, and all other costs ranges between 25-40% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 20-25%, and net profit lie between the range of 10-15% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the biogas manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 300 tons of biogas per day, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In October 2025, EnviTec Biogas has signed its first contract to construct a biogas upgrading plant with CO2 liquefaction in Belgium in collaboration with Dutch energy supplier Byont. The plant is expected to be finished in July 2026 and will connect to an existing biogas factory. It will supply the Belgian gas system with 735 Nm³/h of biomethane.

- In May 2025, TotalEnergies and HitecVision, a Norwegian energy-focused investment firm, have inked a Sale and Purchase Agreement (SPA) for the sale of 50% of Polska Grupa Biogazowa ("PGB") for an enterprise value of €190 million. PGB leads Poland in biogas production with 20 operational units that can produce more than 450 GWh of equivalent biomethane.

- In March 2025, the largest anaerobic digestion facility in the nation was recently put into service by EnviTec Biogas, a biogas expert that is enhancing its collaboration with SJI Renewable Energy Ventures and regional suppliers through its U.S. subsidiary. Since the year began, the South Dakota facility has been processing more than 300,000 gallons (1,100 cubic meters) of manure from over 9,500 dairy cows every day.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104