Coco Peat Manufacturing Cost Analysis: Efficiency and Value Creation

What is Coco Peat?

Coco peat, or coir pith or coir dust, is a fibrous natural byproduct generated during the processing of coconut husks to extract coir fiber. Coco peat is an organic, renewable, and biodegradable product that has gained international significance as a sustainable substitute for peat moss in horticulture, agriculture, and hydroponics. The coco peat production process starts with the gathering of coconut husks, which are retted, soaked, and mechanically treated to exclude long coir fibers that are employed in ropes, mats, or brushes.

Key Applications Across Industries:

The leftover fine material, the pith is washed, sieved, dried, and compressed into briquettes, blocks, or grow bags. Coco peat has great water retention, aeration, and nutrient retention capacity, qualifying it as a best-suited growing medium for plants. It has the capability to hold eight times its weight in water without losing air porosity, all of which encourage healthy root development. In addition, it is pH neutral to slightly acidic, light in weight, and immune to fungal infections, further adding to its use in seed germination, greenhouse cultivation, and conditioning of soil. When utilized in potting media or as a single substrate, coco peat enhances the structure of the soil and minimizes the use of chemical fertilizers. Coco peat is totally biodegradable and could be reused after they are composted, promoting environmentally friendly agricultural practices. With increased focus on minimizing the environmental impact of cultivation and with the limited supply of conventional peat resources, coco peat has become an integral part of environmentally friendly growing systems in both small-scale farming and commercial horticultural production globally.

What the Expert Says: Market Overview & Growth Drivers

The global coco peat market reached a value of USD 3.6 Billion in 2024. According to IMARC Group, the market is projected to reach USD 5.4 Billion by 2033, at a projected CAGR of 4.1% during 2025-2033. The global coco peat market is driven by environmental, agri-industrial, and agricultural factors that are compatible with sustainability objectives and resource optimization. Rising demand for sustainable horticultural and hydroponic growing media is one major driver. As conventional peat harvesting destroys wetlands and emits stored carbon, numerous nations are decoupling from peat products, making demand for renewable alternatives such as coco peat very strong. Its higher water holding and aeration capabilities make it especially useful in water- constrained areas, where it allows farmers to lower irrigation requirements and ensure consistency in crop yields. Growth in greenhouse and vertical farming, especially in cities and controlled-environment agriculture, is also driving demand because coco peat provides reliable quality, sterility, and simplicity of handling over natural soil. Additionally, higher production of coconuts globally, dominated by nations like India, Sri Lanka, Indonesia, and the Philippines, provides a consistent supply of raw material, boosting investments in processing and export-based manufacturing units. Environmentally, coco peat promotes circular-economy operations by putting agro-waste into value-added products instead of sending it to landfills or incinerating coconut husk. Both its biodegradable nature and chemical-free status render it desirable for organic agriculture and eco-certified crops. Furthermore, government efforts encouraging sustainable agriculture, together with growing consumer interest in environmentally friendly cultivation inputs, are building international acceptance. Combined, these drivers, environmental sustainability, growing agriculture technology, raw material supply abundance, and policy incentives continue to fuel good growth opportunities for coco peat production and international exports.

Case Study on Cost Model of Coco Peat Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale coco peat manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed coco peat manufacturing plant in India. This plant is designed to manufacture 3,500 tons of coco peat annually.

Manufacturing Process: The coco peat production process is a methodical sequence of operations to transform coconut husk waste into a premium, environmentally friendly growing material. The process starts with the procurement of coconut husks, normally from coconut processing plants or copra mills. The husks are initially wetted with water or natural ponds for weeks, a process called retting which is used to soften the husk and break the coir fibers. The softened husks are then mechanically defibrated through the use of coir fiber extraction machines for the purpose of separating long coir fibers from the pithy residue. This quality residue, coir pith or coco peat, is then harvested and washed clean to eliminate any remaining salts and other contaminants that may have an impact on plant growth. The material is then dried in the sun or by mechanical dryers to dry the material to a moisture content of about 10–15% so that it can be compressed and stored for a long period. The dried coco peat is then sieved and screened to obtain a uniform particle size and texture, while removing dust or oversized fibers. The material can be buffed, depending on its application, wherein it is treated with calcium or magnesium solutions to restore pH and replace excessive sodium and potassium ions. Lastly, the treated coco peat is then pressed into blocks, briquettes, grow bags, or loose-fill bales with hydraulic presses, making it convenient to store and transport. Every batch is EC (electrical conductivity), pH, and water content quality tested before it is packaged. The outcome is a light, clean, and renewable substrate well suited for horticulture and hydroponics globally.

Get a Tailored Feasibility Report for Your Project Request Sample

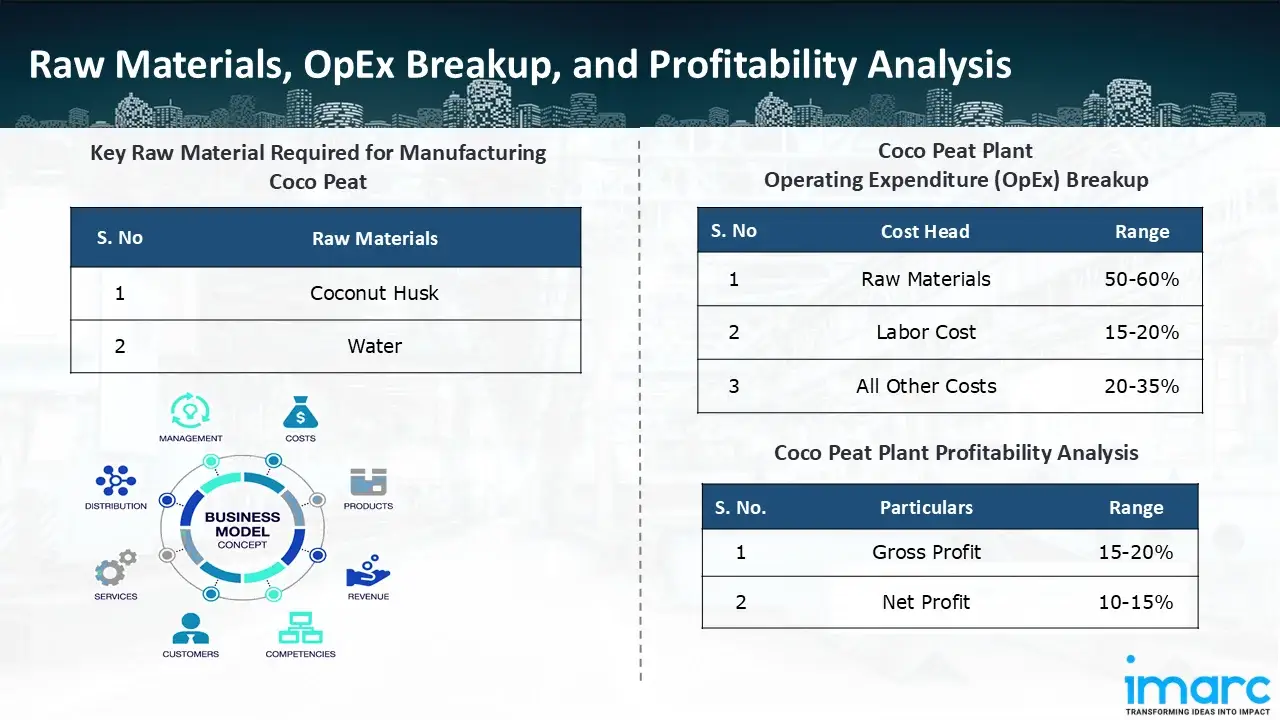

Raw Material Required:

The basic raw materials required for coco peat manufacturing include:

- Coconut Husk

- Water

Machineries Required:

- Conveyor Belts

- Trolleys

- Storage Unit

- Vibrating Screen

- Soaking Tank with Agitators

- Water Pumps

- Rotary Drum Washer

- Buffered Soaking Tank

- Chemical Dosing Pump

- Rinsing Tank

- Solar Drying Bed

- Hot Air Dryer

- Rotary Drum Dryer

- Mechanical Turner/Conveyor

- Air Blower

- Cyclonic Separator

- Hydraulic Block Press

- Screw/Hydraulic Press

- Bagging Machine

- Shrink Wrap Machine

- Palletizer

- Weighing Scale

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in a coco peat manufacturing plant ranges between 50-60%, labor cost ranges between 15% to 20%, and all other costs ranges between 20-35% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 15-20%, and net profit lie between the range of 10-15% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the coco peat manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 3,500 tons of coco peat annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In September 2025, Hayleys Fibre PLC, a player in Sri Lanka's coir and coco peat industry, has expanded its operations with the establishment of the country's first fully integrated coir manufacturing facility in Kadigawa, Nikaweratiya.

- In April 2025, Gro-Med, a division of Vaighai Agro, opened its third coco peat grow bag manufacturing unit at Salem in India. This comes on top of plants already available at Pollachi and Dindigul as a means of satisfying the increased demand for coco coir substrates of quality for sustainable cultivation and peat-free farming.

- In January 2025, the government intends to alter the 72-year-old Coir Industry Act and add value-added products such rubber blended coir and jute in order to increase exports. The goal of cutting the coir board size by 50% is to make decisions more quickly. Additionally, the initiative proposes producer export facilitation hubs.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104