Container Cost Model: Balancing Cost, Quality & Sustainability

What is Container?

Containers are standardized, tough, watertight containers for efficient storage and transportation of goods by ship, rail, and truck without the need for handling the cargo itself.

Key Applications Across Industries:

They are the lifeblood of global trade and logistics, allowing for effective intermodal transport. Constructed from high-strength steel, aluminum, or composite materials, they are designed to withstand rigorous marine and environmental elements. The most common types are dry storage containers for general cargo; however, there are also refrigerated (reefers) for perishables, tank containers for liquids and gases, open-top and flat-rack for oversized equipment, and high-cube for voluminous cargo. Standardization, mainly through ISO specifications, allows for seamless compatibility and efficiency throughout global logistics systems. The modern container revolutionized world trade by simplifying loading, unloading, and inventory management, which reduced transport time and costs drastically. Beyond logistics, the containers are increasingly being repurposed for modular architecture, housing, pop-up retail units, and industrial storage, reflecting their versatility and sustainability. The manufacturing process consists of sheet cutting, frame assembly, wall panel welding, flooring installation, painting, and quality inspection, with rigorous checks on structural strength and anti-corrosion performance. The manufacturers continuously innovate to improve weight efficiency, durability, and energy performance, especially in refrigerated and smart containers equipped with IoT sensors for real-time monitoring. Efficient containers are becoming an important factor as international trade, e-commerce, and logistics networks continue to grow, shaping modern supply chains and global economic connectivity.

What the Expert Says: Market Overview & Growth Drivers

The global shipping container market reached a value of USD 11.9 Billion in 2024. According to IMARC Group, the market is projected to reach USD 21.5 Billion by 2033, at a projected CAGR of 6.72% during 2025-2033. The main factors driving the global container manufacturing market are the expansion of international trade, the globalization of supply chains, and the rapid development of e-commerce and logistics infrastructure. Global trade volumes have soared, increasing demand for new, efficient, and standardized containers that can facilitate the movement of goods across the globe. A contributory factor has also been the latest acceleration in the modernization of maritime transport, with major shipping lines investing in larger, more sustainable vessels, hence further boosting demand for high-capacity containers that optimize cargo utilization.

Further, growth in intermodal transportation systems, wherein goods move seamlessly from sea to rail to road, also reinforces demand for standardized and robust containers capable of withstanding multiple handling cycles. The market is also being driven by technological changes and digitalization. Smart containers fitted with IoT sensors and GPS tracking enable real-time tracking of cargo condition, temperature, and location, which is increasingly important for the pharmaceutical industry, frozen foods, and electronics. Sustainability considerations are another significant driver. Manufacturers are considering greener materials, energy-efficient production methods, and recyclable components for their goods to meet global aims of carbon reduction and to answer the call of increasingly demanding environmental legislations. Besides, the more recent development of modular construction and container-based architecture has unlocked new revenue streams, with upcycled shipping containers increasingly put into service as living quarters, offices, and shopping outlets owing to their affordability and mobility. Geopolitical factors such as reshoring of manufacturing, regional trade agreements, and infrastructure investments in emerging economies further influence container demand. Finally, post-pandemic supply chain restructuring and modernization projects at various ports around the world have spurred orders for both traditional and specialized containers, ensuring the sector's continued global growth and innovation.

Case Study on Cost Model of Container Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale container manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed container manufacturing plant in India. This plant is designed to manufacture 2,500 units of containers annually.

Manufacturing Process: The manufacturing process of a container involves a series of carefully controlled and standardized steps to ensure structural strength, weather resistance, and compliance with international shipping standards. The process begins with the selection of high-quality raw materials, typically corrosion-resistant Corten steel or, in some cases, aluminum or composite panels for lightweight containers. These materials are cut into panels for the floor, walls, roof, and doors using automated CNC cutting and plasma machines to achieve precise dimensions. Once the panels are cut, they undergo surface treatment and cleaning to remove impurities, ensuring proper adhesion during welding and painting. The next stage is frame assembly, where the base frame, corner posts, and roof rails are welded together to form the structural skeleton of the container. The side walls and roof panels are then welded or riveted to the frame, followed by the installation of the end walls and double-leaf doors. The doors are fitted with locking bars, hinges, and rubber seals to ensure airtightness and protection against moisture. After the metal structure is completed, wooden or bamboo flooring panels, often marine-grade plywood treated with anti-fungal coatings, are installed and fastened to the steel cross-members of the base frame. After assembly, the container is sandblasted and primed, followed by several coats of corrosion-resistant paint, usually via automated spray booths. Once painting is done, the container is sent into curing ovens for long-term surface protection. Finally, it undergoes rigorous quality testing, including but not limited to dimensional inspection, water leakage tests, and load-bearing evaluations, before being certified under ISO standards and prepared for branding and labelling for shipment to clients around the world.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

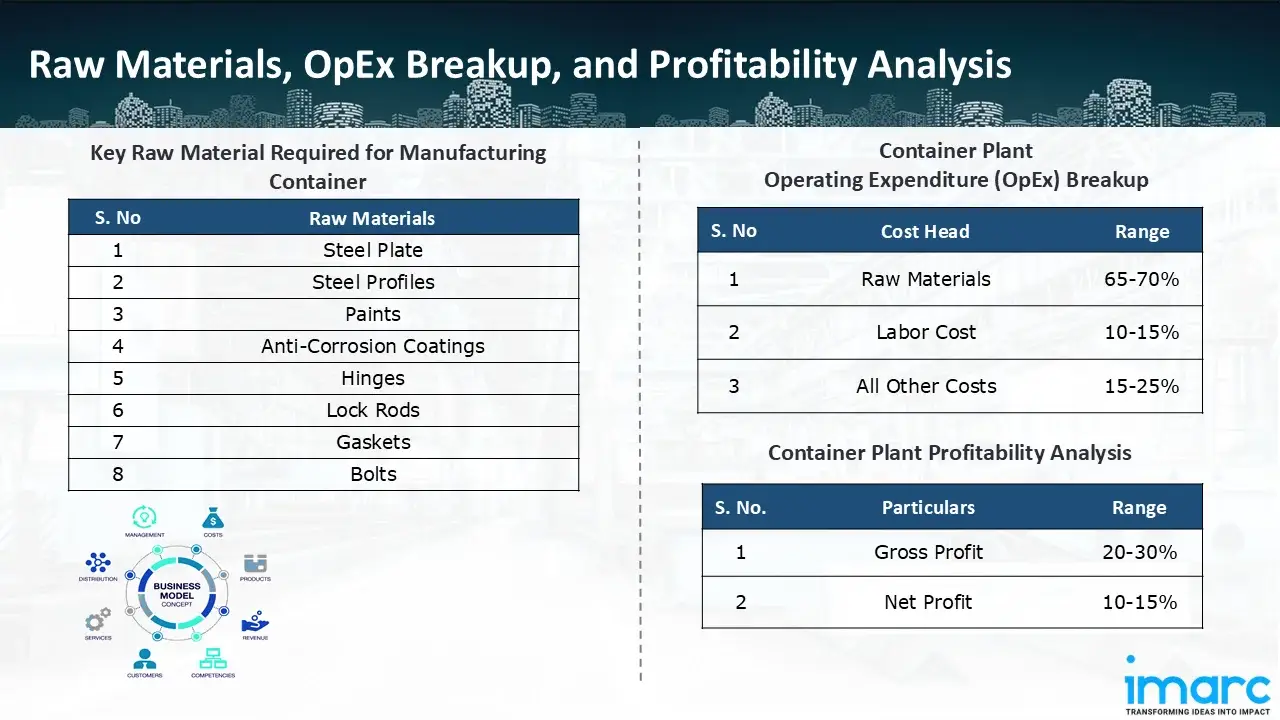

The basic raw materials required for container manufacturing include:

- Steel Plate

- Steel Profiles

- Paints

- Anti-Corrosion Coatings

- Hinges

- Lock Rods

- Gaskets

- Bolts

Machineries Required:

- CNC Plate Cutting Machine / Laser Cutter / Plasma Cutter

- Hydraulic Press Brake / Bending Machine

- Profile Cutting & Punching Machine

- Robotic Welding Line / Mig & Tig Welding Machines

- Seam Welding Machine

- Fixture Jigs & Assembly Rigs

- Floor Fitting Jigs

- Riveting / Screw Machines

- Sand Blasting Machines / Shot Blasting Machines

- Primer & Paint Spray Booths / Automatic Painting Line

- Lock Rod Welding / Fitting Machines

- Rubber Sealing Machines

- Dimensional Checking Fixtures

- Load & Stress Testing Equipment

- Leak Testing

- Painting Inspection Tools

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in a container manufacturing plant ranges between 65-70%, labor cost ranges between 10% to 15%, and all other costs ranges between 15-25% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 20-30%, and net profit lie between the range of 10-15% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the container manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 2,500 unit of containers annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In August 2025, India has started rolling out "Made-in-India" shipping containers from a new manufacturing hub in Bhavnagar, Gujarat, under the Indian government's "Make in India" and "Aatmanirbhar Bharat" initiatives. The facility, run by Aawadkrupa Plastomech Pvt. Ltd. and its subsidiary APPL Containers Pvt. Ltd., currently produces about 15 containers per day, with infrastructure in place to scale output to 100 containers per day.

- In March 2025, container glass producer AGI Greenpac announced its plans to establish a greenfield production facility worth INR 700 crore in Madhya Pradesh. The company's manufacturing presence will be strengthened and its current glass factories in Telangana will be complemented by the expansion. Following its Board approval on Monday, AGI Greenpac stated that it will assist meet the growing demand for premium glass packaging products and boost the company's container glass manufacturing production capacity by 25%.

- In May 2024, Sellwin Traders Ltd. announced the approval by its board of directors to the proposal to make strategic investment in Patel Container India Pvt Ltd. Over the next two years, the company will purchase a 36% share in Patel Container, which can be increased to 51%. Sellwin Traders' investment would be used to help build a new logistic container manufacturing facility in Gujarat's Bhavnagar District.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104