How to Set Up a Manufacturing Plant in Vietnam: A Comprehensive Guide

Establishing a manufacturing plant in Vietnam can offer significant growth opportunities for businesses looking to expand their operations in Southeast Asia. With its rapidly developing infrastructure, competitive labor market, and strategic location, Vietnam has emerged as a leading destination for global manufacturing investments. The country’s favorable business climate, coupled with government support, makes it an attractive option for manufacturers across various industries.

However, setting up a manufacturing facility in Vietnam requires careful planning, compliance with local regulations, and a deep understanding of the market. Here’s a practical guide covering the major points from incentives and site selection to navigating common challenges.

Why Vietnam is an Ideal Place for Setting up a Manufacturing Plant?

- Rapidly Expanding Industrial Base

Vietnam's industrial sector has experienced rapid growth, driven by government initiatives, international trade agreements, and foreign investment. The “Vietnam Industry 4.0” program focuses on technological advancement, automation, and sustainable manufacturing, offering incentives to global manufacturers. Aligned with this, in May 2025, WHA Group further accelerates market development with two new industrial zone projects in Thanh Hoa and Hung Yen provinces, enhancing the country's industrial base, fostering growth, and strengthening its presence across five provinces.

- Strategic Location for Trade

Vietnam’s geographical location in Southeast Asia gives it a strategic advantage as a manufacturing hub. The country shares borders with China, Laos, and Cambodia, offering direct access to regional markets. Vietnam also boasts well-established port infrastructure, such as the deep-water Hai Phong Port in the north and Tan Son Nhat International Airport in Ho Chi Minh City, which facilitates easy access to global shipping routes. These logistical advantages make Vietnam an ideal base for both domestic production and international trade, ensuring smooth transportation of goods to markets across Asia and beyond.

- Business-Friendly Policies

Vietnam’s government has long been committed to creating a business-friendly environment for foreign investors. The country offers 100% foreign ownership in many industries, a low corporate tax rate, and several free trade agreements (FTAs) for cost-effective exports. Concurrent with this, in May 2025, Vietnam's government introduced key resolutions to foster private sector growth, focusing on reducing regulatory barriers, digitalizing public services, and supporting SMEs.

Significant Advantages of Setting Up a Manufacturing Plant in Vietnam:

- Government Support and Incentives

The Vietnamese government has put in place numerous policies to encourage foreign investment in manufacturing, including:

-

- Tax Breaks: The government offers tax holidays and reduced tax rates for businesses that set up in designated industrial zones or focus on sectors such as technology and renewable energy.

- Financial Assistance: The Vietnam Development Bank (VDB) offers competitive loans for industrial projects, helping companies with their initial investment.

- Free Trade Zones (FTZs): Vietnam has several FTZs offering incentives such as zero customs duties, tax exemptions, and simplified business registration processes for foreign manufacturers.

- Tax Breaks: The government offers tax holidays and reduced tax rates for businesses that set up in designated industrial zones or focus on sectors such as technology and renewable energy.

- Modern Infrastructure and Connectivity

Vietnam's infrastructure has seen significant improvements in recent years, making it an ideal location for setting up a manufacturing plant. The country has modern industrial parks, advanced transportation networks, and reliable utilities. Its well-developed road and rail networks, along with deep-water ports and international airports, ensure efficient logistics for transporting raw materials and finished goods.

- Skilled and Cost-Effective Workforce

Vietnam offers a competitive advantage in terms of labor costs and the availability of skilled workers. The country’s workforce is growing rapidly, with millions of young, educated, and technically skilled workers. The government’s focus on vocational training ensures that there is a steady stream of skilled labor available for the manufacturing sector.

- Intellectual Property (IP) Protection

Vietnam has made significant strides in strengthening its intellectual property laws, offering strong protections for patents, trademarks, and industrial designs. These legal safeguards provide manufacturers with the confidence to invest in research and development and protect their proprietary technologies. The Vietnamese government has improved IP enforcement measures, ensuring that businesses can protect their innovations and prevent counterfeiting or infringement of their rights.

- Domestic Market and Export Reach

In addition to being an attractive destination for manufacturing, Vietnam also offers a thriving domestic market. With a population of over 95 Million people, the country’s growing middle class represents a substantial consumer base for locally manufactured products. Vietnam is a member of several FTAs, such as the Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPP) and the ASEAN Free Trade Area (AFTA), making it an ideal base for exporting goods to other parts of Asia, Europe, and North America.

Industries Driving Vietnam’s Manufacturing Growth:

Vietnam’s manufacturing sector is diverse, with several industries driving growth. Some of the key sectors include:

- Electronics: Vietnam is rapidly becoming a major hub for electronics manufacturing, with companies like Samsung, LG, and Intel setting up production facilities in the country.

- Textiles and Apparel: The textile and apparel industry in Vietnam is one of the largest in the world, with many global brands outsourcing their production to the country.

- Automotive: Vietnam’s automotive industry is growing, with companies such as VinFast and Toyota investing heavily in manufacturing facilities.

- Renewable Energy: With the global push for sustainability, Vietnam is positioning itself as a leader in renewable energy, with increasing investments in solar and wind power manufacturing.

- Food Processing: Vietnam’s food processing sector has expanded to meet the growing demand for packaged foods, beverages, and meat products.

How Long Does It Take to Build a Manufacturing Plant in Vietnam?

The timeline for building a manufacturing plant in Vietnam depends on several factors, including the size of the plant, the type of industry, and the location. On average, it can take:

- Standard Facilities (12–24 Months): Basic manufacturing plants, such as those involved in textiles, food processing, or assembly, can be established within this timeframe.

- Modular Facilities (8–12 Months): Pre-fabricated or modular units can be built more quickly, making this an attractive option for certain industries.

- Heavy Industries (24–36 Months): High-tech industries, such as automotive or electronics manufacturing, may take longer due to the complexity of equipment installation and regulatory approvals.

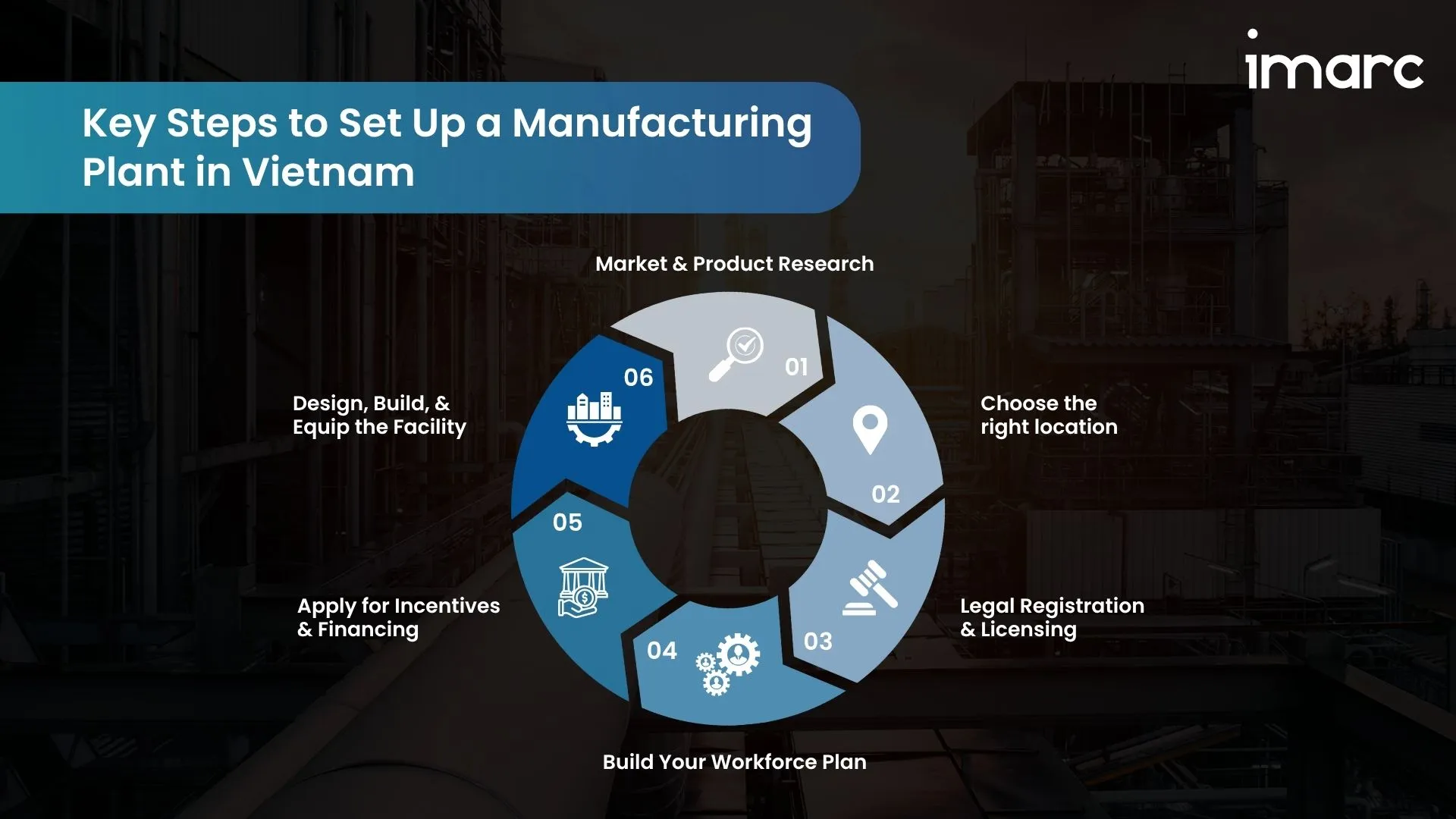

Essential Steps to Set Up a Manufacturing Plant in Vietnam:

1. Market and Product Research

Study the demand within Vietnam and across the ASEAN region. Understand import and export trends, analyze customs duties, and evaluate local competition. Relevant insights can be gathered from the Vietnam Chamber of Commerce and Industry (VCCI), the Ministry of Industry and Trade, and other local trade bodies.

2. Choose the Right Location

Vietnam offers diverse options for establishing manufacturing plants, including industrial zones and business parks. Industrial zones provide infrastructure and incentives, while business parks may offer flexibility in location and local sales. Key factors to consider include:

- Proximity to suppliers and raw materials

- Access to major ports and airports for efficient transportation

- Utility reliability and cost-effectiveness

- Zoning regulations for environmental and safety compliance

3. Legal Registration and Licensing

To operate in Vietnam, you must register your business with the Department of Planning and Investment (DPI) for mainland operations or with the relevant industrial zone authority. You will need to acquire:

- A business registration certificate

- An investment license

- Environmental impact assessments from local authorities

- Work permits and visa quotas for foreign employees

4. Build Your Workforce Plan

Consider your workforce needs and create a recruitment plan to hire skilled labor. Vietnam offers a blend of local and international talent, with a strong labor force in both skilled and unskilled sectors. Collaborate with vocational training institutes and universities to meet specific hiring needs.

5. Apply for Incentives and Financing

Seek financing options from local banks or entities such as the Vietnam Development Bank. Explore various incentives available in industrial zones or through government agencies like the Ministry of Planning and Investment (MPI), which may include lease deals, customs support, and financial assistance for infrastructure or machinery.

6. Design, Build, and Equip the Facility

Plan your plant layout based on production requirements. Once the design is finalized, install the necessary machinery, connect utilities, and ensure compliance with Vietnam's environmental and safety standards. Work with local contractors and engineers to ensure the facility is built to code and operational on schedule.

Real-World Challenges to Plan For:

- Complex Approvals: Vietnam’s regulatory environment can be complex, and approval processes may vary by region. Coordinating with both local and federal authorities is necessary to ensure that all required permits are obtained on time.

- High Setup Costs: Land acquisition, machinery, and construction costs can add up quickly. While free zones offer financial incentives, setup costs can still be significant. Working with local partners and exploring financing options can help manage these costs.

- Workforce Management: While the workforce is generally skilled, recruiting for high-tech industries or specific roles may require additional training and investment. Ensuring compliance with labor laws and managing visa requirements for foreign workers are also crucial factors to consider.

- IP Protection and Enforcement: Vietnam has made strides in strengthening its IP protection laws, but manufacturers must actively register their patents and trademarks to avoid potential infringements.

How IMARC Supports Manufacturing Expansion in Vietnam:

IMARC helps businesses navigate the complexities of setting up manufacturing plants in Vietnam with detailed market research, strategic guidance, and pre-feasibility studies. Our services include:

- Market Research and Strategic Insights: Offering data-driven insights into demand trends, regional trade prospects, and local competition to position your products effectively.

- Pre-Feasibility Studies: We provide comprehensive feasibility studies, including cost estimates, market analysis, and site selection evaluation.

- Cost Estimation and Financial Analysis: We assist in budgeting and planning, offering a breakdown of costs and projections for working capital, equipment, and staffing.

- Regulatory Compliance and Licensing: IMARC guides businesses through the legal processes involved in setting up a manufacturing plant in Vietnam, ensuring compliance with local regulations.

Final Note:

Setting up a manufacturing plant in Vietnam presents a unique opportunity to tap into the growing industrial base in Southeast Asia. With a competitive workforce, strong government support, and strategic access to global markets, Vietnam offers significant rewards for manufacturers. By carefully managing the setup process, from market research to location selection and regulatory compliance, businesses can thrive in Vietnam’s dynamic manufacturing environment.

IMARC is here to support you every step of the way, from feasibility studies to site selection, financing, and scaling production. Ready to set up your manufacturing plant in Vietnam? Contact us today to get started!

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104