Nutritional Powder Manufacturing: Cost Breakdown and Financial Projections

_11zon.webp)

What is Nutritional Powder?

Nutritional powders have become essential nutritional supplements created to address the specific health needs of vulnerable demographics, including diabetic patients, the aged, and the sick. When regular food intake is inadequate or compromised, these powders, which are made with specially designed compositions and are high in vital vitamins, minerals, protein, and carbs, offer balanced nourishment.

Key Applications Across Industries:

Specialized baby formulas guarantee the best possible growth and development in the early years of life. Powders that support muscle maintenance, immunity, and recovery are beneficial for the elderly and convalescent, particularly in cases when appetite or digestion are compromised. The low glycaemic index, high fibre, and controlled sugar content of diabetes-specific nutritional powders also aid in glycaemic control management. Clinical professionals are increasingly prescribing nutritional powders and incorporating them into therapeutic care as healthcare systems place an emphasis on supporting and preventative nutrition.

What the Expert Says: Market Overview & Growth Drivers

The global nutritional powder market reached USD 17.11 Billion in 2024. According to IMARC Group, the market is projected to reach USD 35.96 Billion by 2033, growing at a CAGR of 8.6% from 2025 to 2033. The ageing population, growing awareness of preventative healthcare, and the increasing prevalence of chronic diseases worldwide are driving the market for nutritional powder.

Demand for focused nutritional therapy has increased, particularly due to the rise in diabetes, geriatric malnutrition, and an increase in premature or low-weight newborns. Additionally, nutritional powders have gained legitimacy as efficient medical nutrition solutions because to clinical endorsements, hospital-based nutrition programs, and the growth of home healthcare. Furthermore, these powders are becoming more enticing and useful due to developments in ingredient innovation, such as plant-based proteins, low-sugar formulations, and probiotic-enriched blends. The nutritional powder market is still growing through retail, hospital, and internet distribution channels as consumers and carers look for personalized and convenient solutions.

Case Study on Cost Model of Nutritional Powder Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a large-scale nutritional powder manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed nutritional powder manufacturing plant in Myanmar. This plant is designed to produce 3,240 tons of nutritional powders annually.

Manufacturing Process: The manufacturing process of nutrition powder for elderly and ill begins with the careful selection and testing of high-quality ingredients, including proteins, carbohydrates, healthy fats, vitamins, minerals, and additives like probiotics and fiber. These ingredients undergo precise weighing and thorough mixing to ensure uniformity. If required, wet processing is performed by adding liquid nutrients or flavorings for improved taste and nutrient dispersion. Granulation may follow to enhance flow properties and compressibility, with the mixture then dried using methods like spray drying or fluid bed drying to achieve optimal moisture content. The dried powder is milled or sieved to attain the desired particle size, ensuring consistency. Packaging is carried out using automated machinery that preserves freshness and ensures accurate dosing, followed by labeling and serialization for transparency, safety, and traceability. Finally, the product is stored in climate-controlled facilities and distributed through efficient logistics channels to maintain its quality until it reaches consumers.

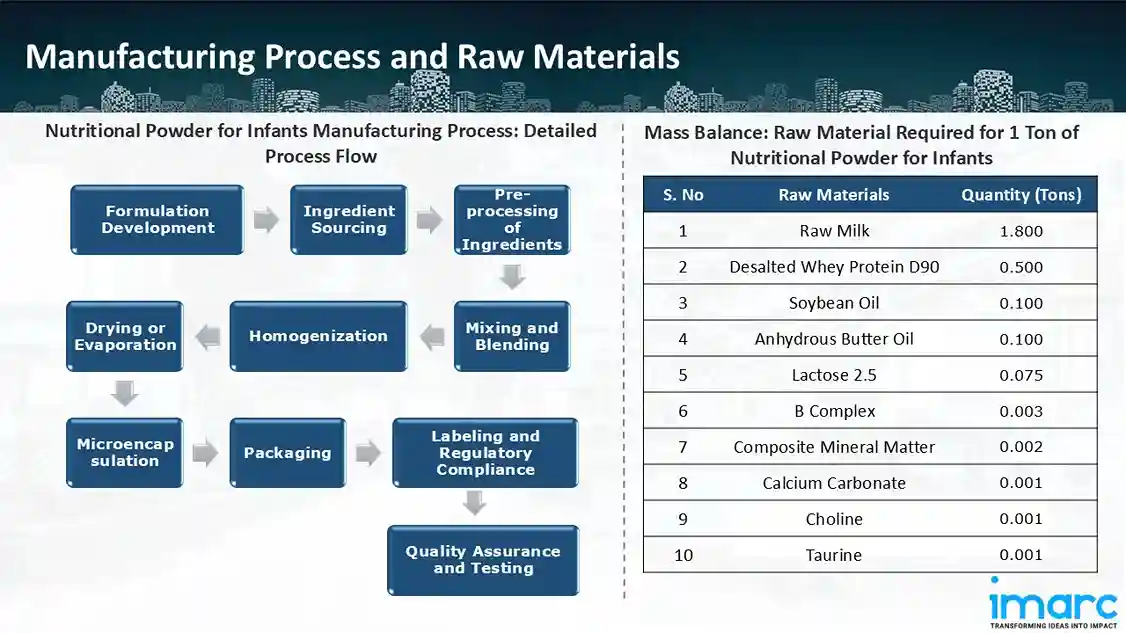

The production of infant nutrition powder follows a rigorous multi-stage process for achieving maximum safety, quality, and nutritional content. Formulation development establishes the exact macronutrient and micronutrient composition per 100 kcal or 100 kJ, specifically adapted to infants' nutritional requirements. High-quality ingredients such as milk proteins, carbohydrates, vegetable oils, and essential vitamins and minerals are carefully procured and adhere to high-quality standards. Pre-processing involves pasteurization, homogenization, and milling to guarantee safety, consistency, and digestibility. Ingredients are measured and mixed during mixing and blending for uniform nutrient delivery. Homogenization adds texture and stability by evenly dispersing fat globules. Evaporation or drying removes water while retaining nutrients and producing the required powder form. Microencapsulation is an optional step to protect sensitive nutrients from degradation. The powder is thus packaged in sealed, food-grade containers to ensure freshness and protection from contamination. Labels are created strictly according to regulatory requirements to provide transparency and consumer confidence. Lastly, stringent quality control and testing ensure safety, purity, nutrient integrity, and infant nutrition guideline compliance, ensuring a high-quality product that can be safely consumed by infants.

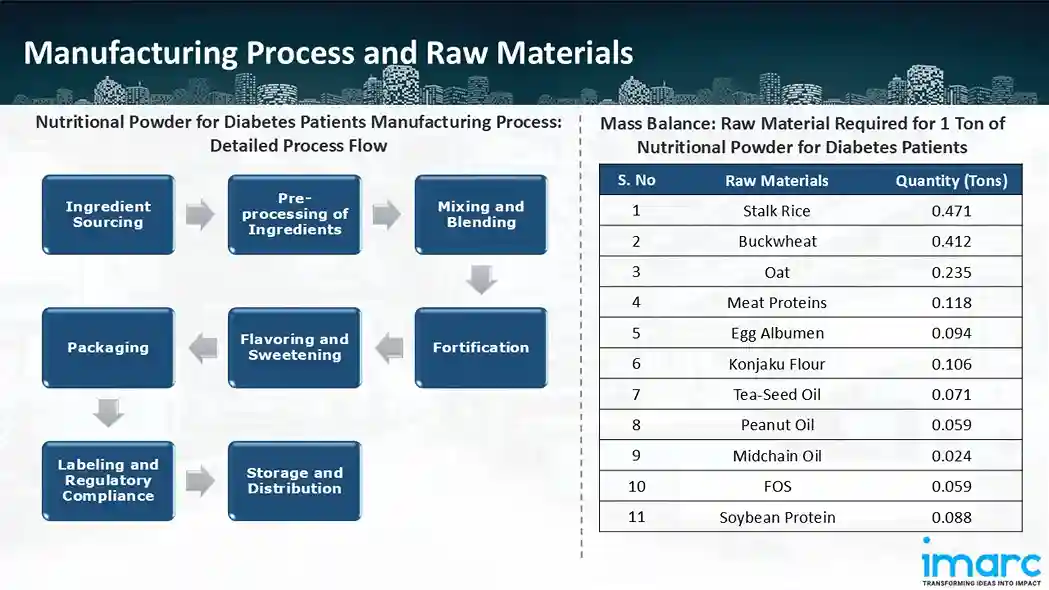

Manufacturing nutrition powder for diabetics requires several accurate steps to achieve quality, safety, and effectiveness. It starts with purchasing quality ingredients such as whey protein isolate, complex carbohydrates (e.g., barley, oats), healthy fats (e.g., coconut oil, flaxseed), and necessary vitamins and minerals from credible suppliers to address certain dietary requirements. Pre-processing is then conducted through grinding, milling, or extraction to maximize nutrient bioavailability and digestibility. During the blending and mixing phase, ingredients are evenly mixed with specialized machinery to maintain texture consistency and nutritional equivalence. Fortification supplements specific micronutrients to counteract typical diabetic dietary deficiencies, while flavoring and sweetening employ safe alternatives such as stevia or erythritol to enhance flavor without elevating blood sugar. The end product is packaged in consumer-friendly containers such as sachets or pouches, with quality-checked labeling compliant with regulatory requirements and offering clear nutrition labeling. Finally, storage and transportation are handled under controlled conditions to ensure freshness and prompt delivery through wholesale, retail, or direct-to-consumer routes.

Process 1

_11zon.webp)

Process 2

Process 3

Mass Balance and Raw Material Required: The primary raw materials used in the nutritional powder for elderly and ill manufacturing plant include spirulina, wheat, wheat embryo, Chinese yam, naked oats, lotus seeds, the root of Kudzu vine, ripe walnut kennel, gorgon fruit and sugar. For a plant producing 1 ton of nutritional powder for elderly and ill, 0.188 ton of spirulina, 0.182 ton of wheat, 0.195 ton of wheat embryo, 0.231 ton of Chinese yam, 0.097 ton of naked oats, 0.122 ton of lotus seeds, 0.122 ton of the root of Kudzu vine, 0.134 ton of ripe walnut kennel, 0.134 ton of gorgon fruit and 0.024 ton of sugar are required.

The primary raw materials used in the nutritional powder for infants manufacturing plant include raw milk, desalted whey protein D90, soybean oil, anhydrous butter oil, lactose 2.5, B complex, composite mineral matter, calcium carbonate, choline and taurine. For a plant producing 1 ton of nutritional powder for infants, 1.8 ton of raw milk, 0.5 ton of desalted whey protein D90, 0.1 ton of soybean oil, 0.1 ton of anhydrous butter oil, 0.075 ton of lactose 2.5, 0.003 ton of B complex, 0.002 ton of composite mineral matter, 0.001 ton of calcium carbonate, 0.001 ton of choline and 0.001 ton of taurine are required.

The primary raw materials used in the nutritional powder for diabetes patients manufacturing plant include stalk rice, buckwheat, oat, meat proteins, egg albumen, konjaku flour, tea-seed oil, peanut oil, midchain oil, FOS and soybean protein. For a plant producing 1 ton of nutritional powder for diabetes patients, 0.471 ton of stalk rice, 0.412 ton of buckwheat, 0.235 ton of oat, 0.118 ton of meat proteins, 0.094 ton of egg albumen, 0.106 ton of konjaku flour, 0.071 ton of tea-seed oil, 0.059 ton of peanut oil, 0.024 ton of midchain oil, 0.059 ton of FOS and 0.088 ton of soybean protein.

List of Machinery:

The following equipment was required for the proposed plant:

- Miller Machinery

- Mixer

- Screw Conveyor

- Twin Screw Extruder

- Air Conveyor

- Electricity Dryer

- Elevator

- Miller Machine

- Ribbon Blender

- Packaging

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

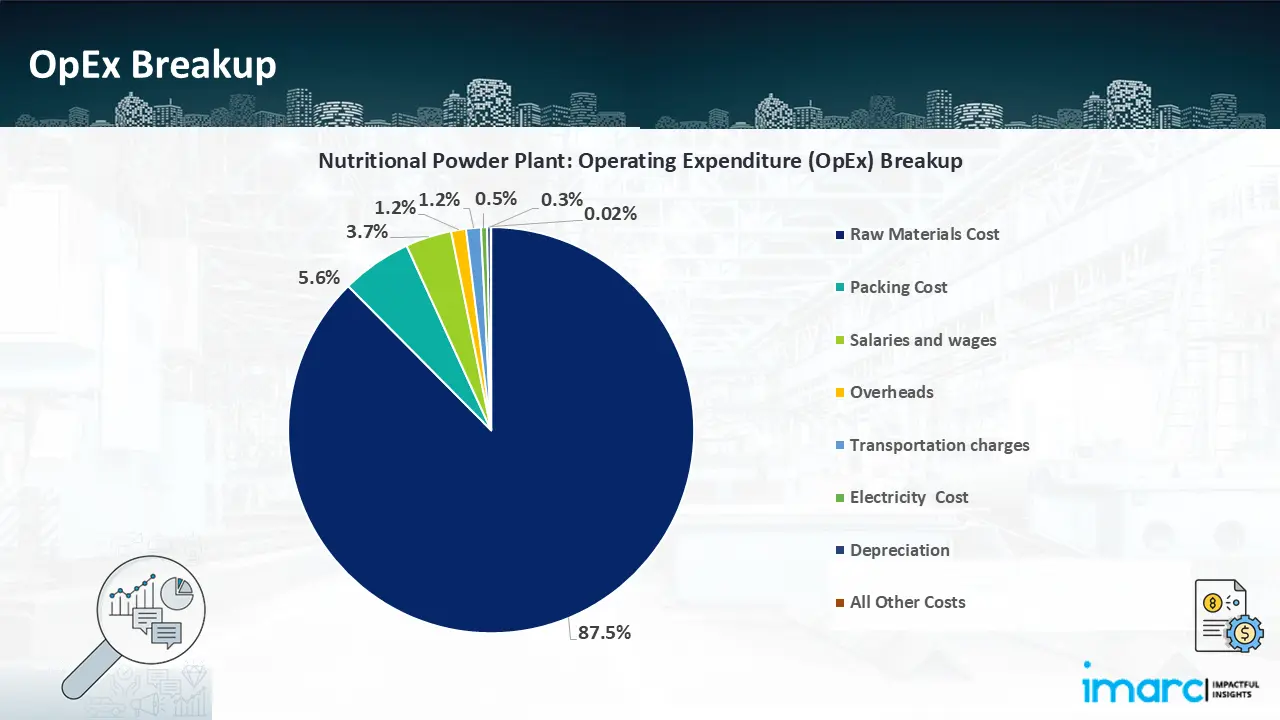

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

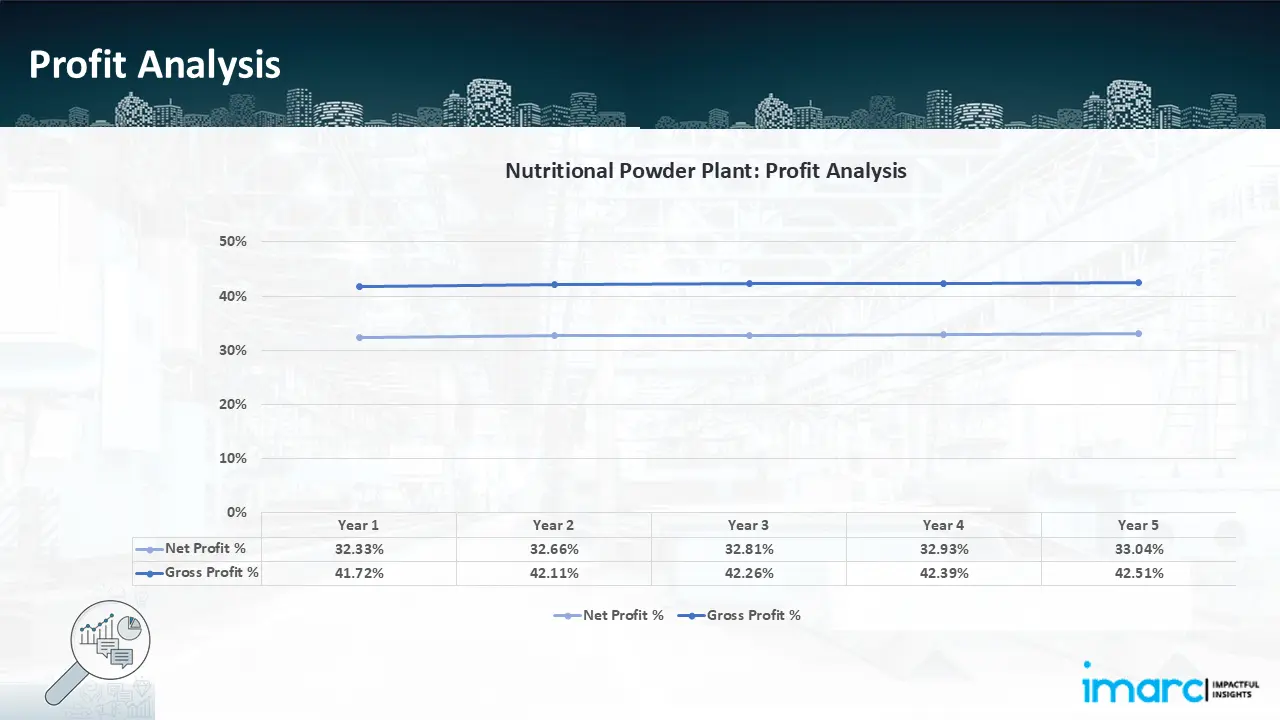

- Profitability Analysis Year on Year Basis: The proposed nutritional powder plant, with an annual capacity of approximately 3,240 tons of nutritional powder, achieved an impressive revenue of US$ 33.7 Million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins improve from 41.72% to 42.51% by year 5, and net profit rises from 32.33% to 33.04%, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the nutritional powder manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of producing 3,240 tons of nutritional powder annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights for strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In November 2024, Tate & Lane bought CP Kelco, a U.S.-based ingredients supplier, which increased its capacity to create nutritious powder and better premix products.

- In May 2024, Vector Consumer (UK) increased its footprint in the nutritional powder and wellness market by purchasing Dose & Co., a manufacturer of collagen supplements. This action comes shortly after the Pura Collagen brand was acquired successfully.

- In February 2024, Herbalife launched the Herbalife® GLP-1 Nutrition Companion is a new line of food and supplement product pairings designed to complement the nutritional needs of those taking GLP-1 and other weight-loss drugs.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104