Optimizing Caustic Soda Production: A Comprehensive Cost Analysis

What is Caustic Soda?

Caustic soda is the common term for sodium hydroxide (NaOH), a versatile alkali widely used in industries such as chemicals, textiles, pulp and paper, detergents, and water treatment.

Key Applications Across Industries:

Sodium hydroxide is known to have strong alkaline properties. It is employed in manufacturing processes such as saponification, pH regulation, and chemical synthesis, making it essential for diversified industrial applications.

What the Expert Says: Market Overview & Growth Drivers

According to an IMARC study, the global caustic soda market by volume was 83.2 Million Tons in 2024, growing at a CAGR of 1.6% from 2019 to 2024. Looking ahead, the market is expected to grow at a CAGR of approximately 1.41% from 2025 to 2033, reaching a projected volume of 95.7 Million Tons by 2033.

The caustic soda market is driven by the extensive application in various industries. There is a rise in demand from the pulp and paper industry to bleach and process paper, hence fueling significant growth in the market. Water treatment also propels its usage, as increased concerns about water pollution and scarcity build up. The chemical industry also drives demand because caustic soda is critical in the production of key chemicals such as chlorine, ethylene oxide, and sodium compounds. Additionally, the growing textile and detergent sectors require caustic soda for cleaning and pH regulation. Rapid industrialization and urbanization further amplify the demand for this versatile alkali.

Case Study on Cost Model of Caustic Soda Manufacturing Plant:

Objective

One of our clients has approached us to conduct a feasibility study for establishing a mid to large-scale caustic soda manufacturing plant in Ethiopia.

IMARC Approach: Comprehensive Financial Feasibility

We have developed a comprehensive financial model for the plant's setup and operations. The proposed facility is designed with an annual production capacity of 67 tons of caustic soda per day.

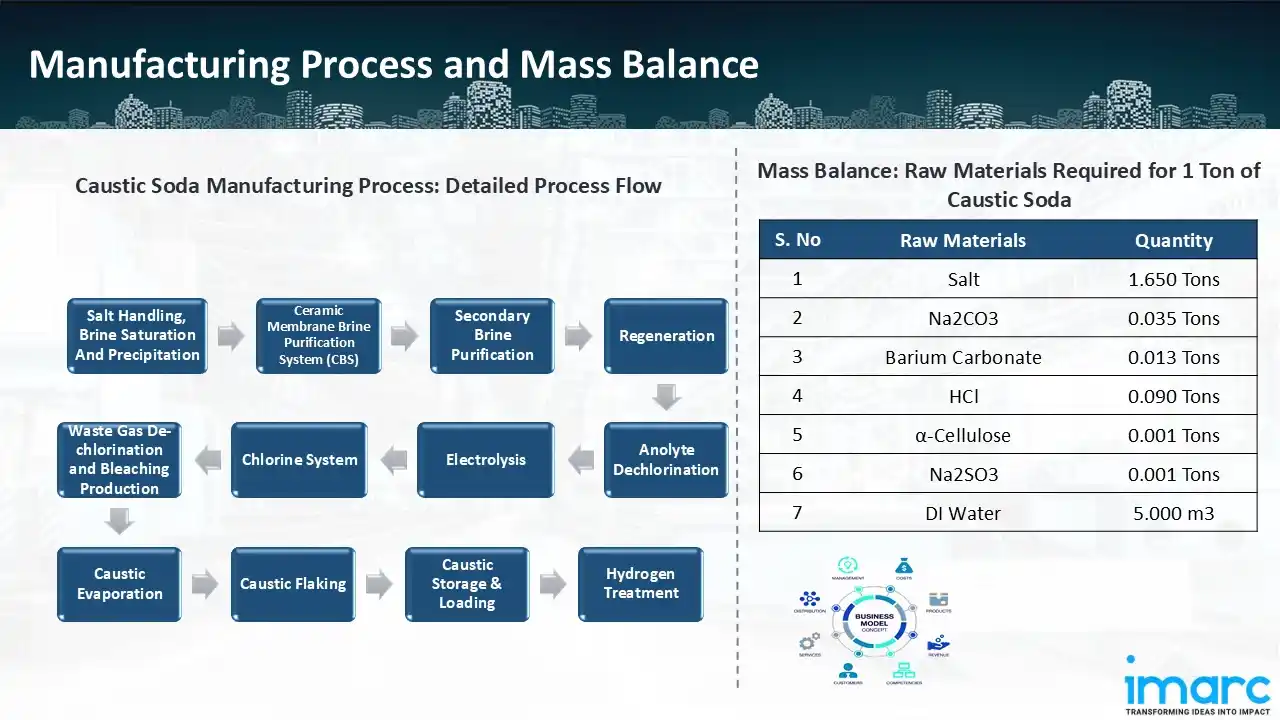

Manufacturing Process: The electrolysis of sodium chloride, commonly known as brine solution, is the key process in caustic soda production. One of three cell types from mercury, diaphragm, or membrane cells is used to electrolyze the saturated brine solution that is first created by dissolving salt in water. While chlorine gas escapes through the anode, the sodium ions move toward the cathode and react with water to form hydrogen gas and caustic soda. The resulting caustic soda solution is concentrated to the needed concentration and purity standards by evaporation. After manufacturing, secondary purification method is used to increase the quality of the caustic soda. Evaporation is then used to concentrate the resultant caustic soda solution to the required concentration and purity levels. Secondary purification techniques are used after manufacture to improve the caustic soda's quality. To get rid of contaminants, this involves anolyte dichlorination and regeneration. Flaking the refined caustic soda makes handling and storage simple. To reduce the process's negative effects on the environment, effective waste management techniques are also incorporated, such as waste gas de-chlorination and bleaching production. All things considered, this all-encompassing strategy guarantees the efficient and sustainable production of high-purity caustic soda.

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials utilized in the caustic soda manufacturing plant include salt, Na2CO3, barium carbonate, hydrochloric acid, DI water, α-Cellulose and Na2SO3. To manufacture 1 tons of caustic soda, we require Salt (1.650 Tons), Na2CO3 (0.035 Tons), Barium Carbonate (0.013 Tons), HCl (0.090 Tons), DI Water (5.000 m3), α-Cellulose (0.001 Tons), and Na2SO3 (0.001 Tons).

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

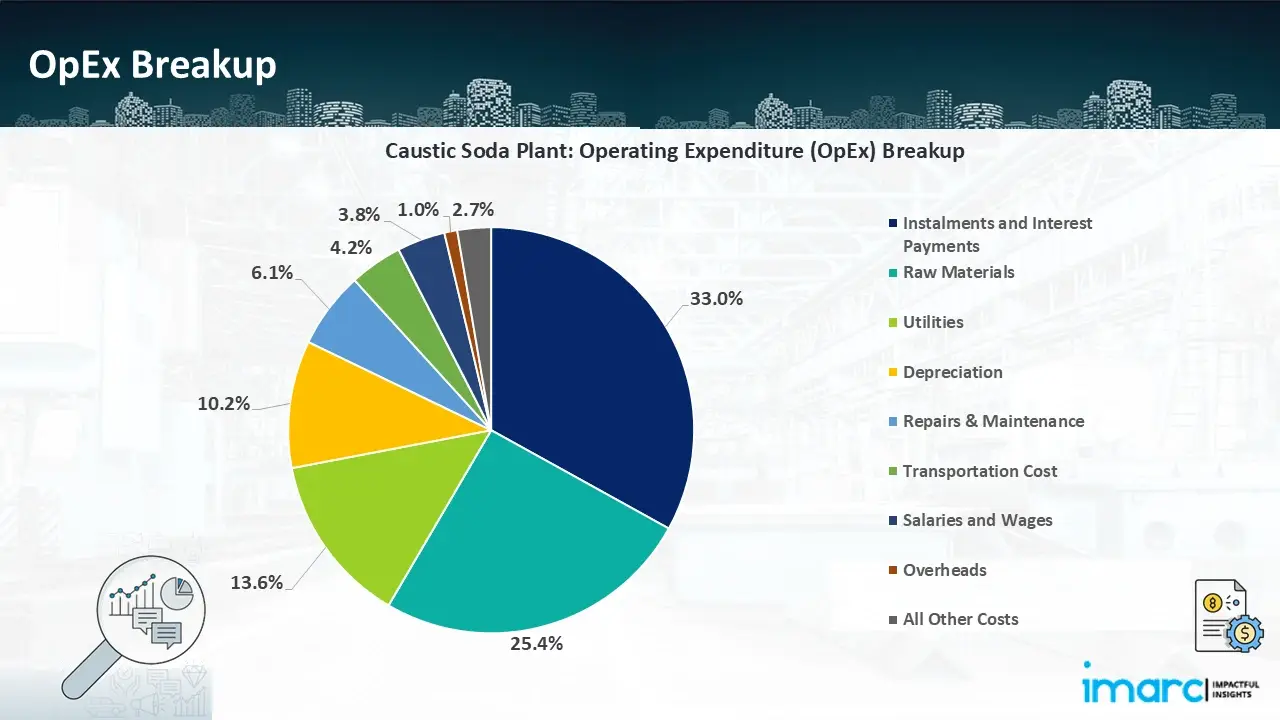

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

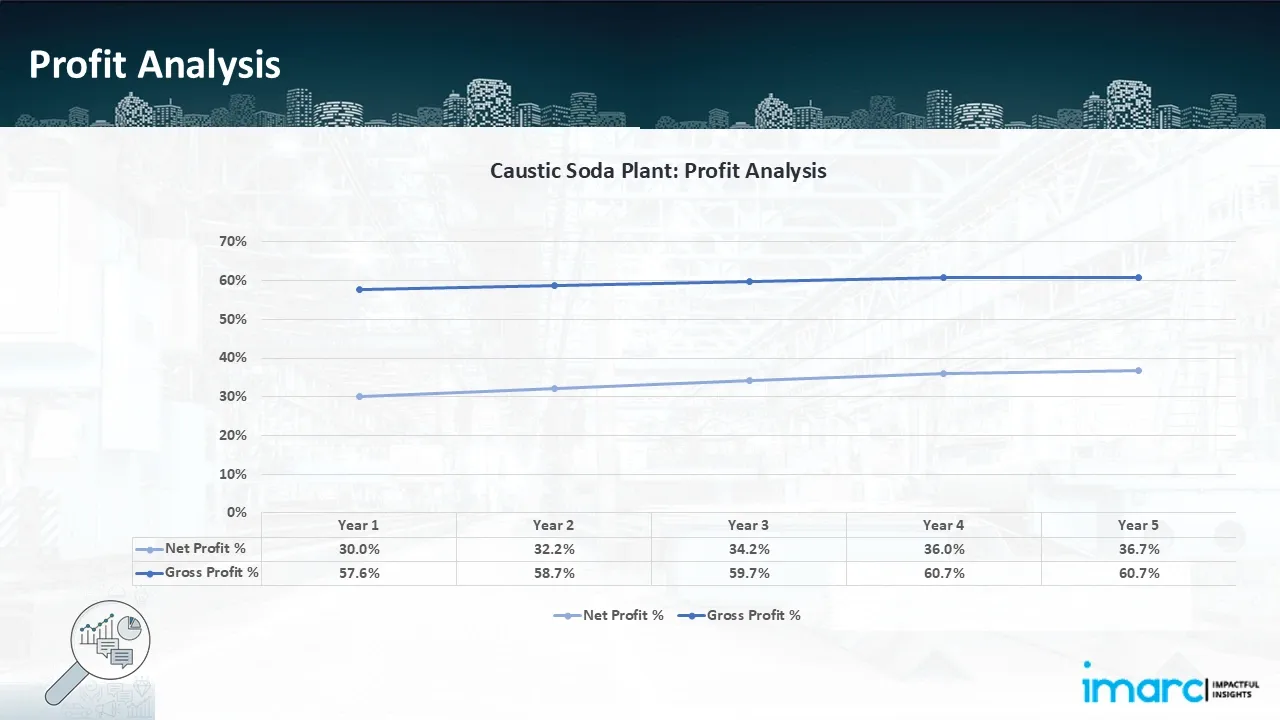

- Profitability Analysis Year on Year Basis: The proposed caustic soda plant, with a capacity of 67 tons of caustic soda per day, achieved an impressive revenue of US$ 24.15 Million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit improved from 57.6% to 60.7%, and net profit rise from 30.0% to 36.7%, highlighting strong financial viability and operational efficiency.

Conclusion & IMARC's Impact:

Our financial model for the caustic soda manufacturing plant was meticulously designed to meet the client’s objectives. It provided a thorough analysis of production costs, including raw materials, manufacturing processes, capital expenditure, and operational expenses. Tailored to the specific requirement of producing 67 tons of caustic soda per day, the model highlights key cost drivers and forecasts profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model offers the client valuable insights for strategic decision-making, demonstrating our commitment to delivering precise, client-focused solutions that ensure the long-term success of large-scale manufacturing projects.

Latest News and Developments:

- In November 2024, ADAMA Ltd. has launched a state-of-the-art chlor-alkali facility, underlining its efforts to strengthen its market position and environmental sustainability. This facility is to answer the growing needs of chlor-alkali chemicals in industries, improve its working efficiency and further reduce its impacts on the environment. The measure demonstrates Adama's commitment toward environment-friendly modes of production while strategically focusing innovation to meet ever-increasing requirements of customers and the market.

- In May 2024, DCM Shriram Ltd. launches its Caustic Soda Expansion Project in Bharuch, Gujarat, marking an important milestone. This project strengthens the company's chemical complex in Jhagadia by adding 850 tonnes per day (TPD). As a result, DCM Shriram's installed capacity at Bharuch alone reaches an amazing 2225 TPD, increasing the caustic capacity to 1 Million Metric Tonnes per annum (TPA) at the plants in Kota, Rajasthan, and Bharuch, Gujarat.

- In January 2024, Atul Products Ltd. (APL), a fully-owned subsidiary of Atul Ltd., has started operating a 50 MW power plant and a 300 tpd caustic-chlorine facility at the Atul site.

- In June 2022, thyssenkrupp nucera has secured a significant order to expand a caustic soda plant for Kutch Chemical Industries in India. In line with sustainable standards and the growing need for caustic soda in industrial applications, the project entails expanding the plant's production capacity utilising Thyssenkrupp Nucera's cutting-edge chlor-alkali technology.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Brief List of Our Services: Market Entry and Expansion

- Market Entry and Opportunity Assessment

- Competitive Intelligence and Benchmarking

- Procurement Research

- Pricing and Cost Research

- Sourcing

- Distribution Partner Identification

- Contract Manufacturer Identification

- Regulatory Approvals, and Licensing

- Factory Setup

- Factory Auditing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104