Japan SCADA Market Expected to Reach USD 2.9 Billion by 2033 - IMARC Group

Japan SCADA Market Statistics, Outlook and Regional Analysis 2025-2033

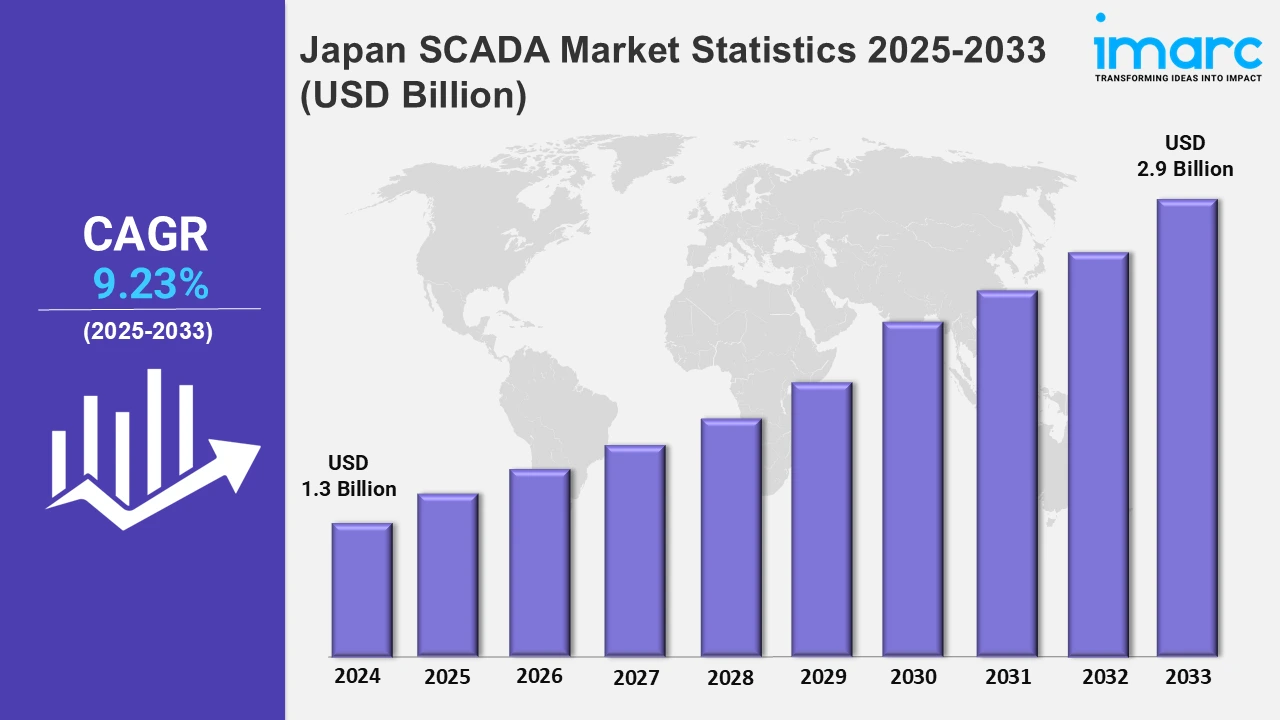

The Japan SCADA market size was valued at USD 1.3 Billion in 2024, and it is expected to reach USD 2.9 Billion by 2033, exhibiting a growth rate (CAGR) of 9.23% from 2025 to 2033.

To get more information on this market, Request Sample

The SCADA market in Japan is witnessing significant growth due to technological advancements, especially in industries that require real-time monitoring, automation, and data-driven insights. Companies are increasingly focusing on enhancing operational efficiency and sustainability, which is driving the adoption of SCADA systems across various sectors. For instance, in March 2024, Lincstech implemented Mitsubishi Electric's GENESIS64 SCADA software at its Shimodate Plant, enhancing operational efficiency through real-time production status visualization and predictive maintenance. This implementation highlights the role of SCADA systems in automating data collection, which, in turn, supports smarter decision-making and increases productivity in industrial settings. In addition to automation, the growing demand for sustainable manufacturing practices is contributing to SCADA's adoption. In January 2024, OMRON launched a demonstration experiment to monitor greenhouse gas emissions in supply chains using SCADA systems in collaboration with NTT Communications, Cognizant Japan, and SALTYSTER. This initiative emphasizes the system's ability to collect and analyze data for improving energy efficiency and supporting environmentally sustainable operations. As industries across Japan strive to reduce their carbon footprints and align with environmental regulations, SCADA systems are becoming increasingly crucial for driving energy productivity improvements and ensuring compliance with sustainability goals.

In Japan, significant trends drive the continued development of SCADA technology. Real-time monitoring and predictive maintenance are becoming important to maximize efficiency and minimize downtime, mainly in the industrial and energy industries. Congruent with these trends, SCADA systems facilitate improved asset management by providing advanced diagnostics, thereby anticipating issues and optimizing maintenance schedules. Apart from that, it reduces the expenses associated with unscheduled shutdowns and repairs while simultaneously increasing operating efficiency. At the same time, the SCADA system's capacity for data collection, real-time analysis, and remote monitoring is improved by its growing integration with industrial IoT networks and the Internet of Things. Concurrent with this, the country's emphasis on automation and smart manufacturing, especially in energy-intensive sectors such as chemicals and power, is favoring the market. These systems are increasingly seen as essential tools for businesses aiming to optimize industrial processes while tackling global environmental concerns.

Japan SCADA Market Statistics, By Region

The market research report has also provided a comprehensive analysis of all the major regional markets, which include Kanto region, Kansai/Kinki region, Central/ Chubu region, Kyushu-Okinawa region, Tohoku region, Chugoku region, Hokkaido region, and Shikoku region. The growing automation of industries such as manufacturing, oil and gas, energy, water, transportation, etc., is encouraging the need for SCADA systems that allow for real-time monitoring and control, further contributing to market growth.

Kanto Region SCADA Market Trends:

The Kanto region, home to Tokyo, is a hub for leading-edge industrial automation and SCADA technology adoption. With industries spanning from energy to manufacturing, there is an increasing demand for these systems to optimize processes and ensure system reliability. In August 2024, Yokogawa launched the OpreX Open Automation SI Kit and OpreX OPC UA Management Package for Open Process Automation (OPA) systems in the region. These innovations are driving efficiency and interoperability, fostering enhanced system security and integration. The Kanto region remains at the forefront of Japan's growth.

Kansai/Kinki Region SCADA Market Trends:

The SCADA industry is growing in the Kansai region due to rising automation in industrial applications. Along with this, the manufacturing sector, especially in the production of automobiles, is a key trend in the growth of this industry. These systems, for instance, are used by DENSO Corporation in Kyoto to optimize its production lines, increasing productivity and reducing downtime. Correspondingly, the region's emphasis on advanced factory initiatives and smart manufacturing is helping to increase the use of these solutions for process monitoring and operational optimization.

Central/Chubu Region SCADA Market Trends:

The Chubu region is witnessing expansion in the SCADA industry driven by a substantial industrial presence, particularly in the automotive and aerospace industries. These systems are used by companies such as Toyota to improve real-time data processing across production units, predictive maintenance, and supply chain monitoring. Moreover, this region is also focused on incorporating SCADA with IoT to enable more intelligent automation in production. Accordingly, improvements in automation and process optimization have a significant impact on the region's need for this system.

Kyushu-Okinawa Region SCADA Market Trends:

The SCADA market is growing in Kyushu-Okinawa driven by higher investments in water treatment and renewable energy technology. Alongside, wind and solar power plants are integrating these systems to track performance and guarantee efficiency. Kyushu Electric Power Company, for example, uses SCADA systems to maximize the efficiency of its renewable energy installations. Besides this, the usage of these systems in the water and waste management sectors is increasing with the region's emphasis on sustainability and smart infrastructure.

Tohoku Region SCADA Market Trends:

SCADA systems are used frequently in the Tohoku region, especially in agricultural and disaster management. These technologies are used for real-time monitoring of vital infrastructure, such as water supply and energy grids. Along with this, municipal utilities in Sendai use these systems to increase operational effectiveness, detect problems early, and distribute energy as efficiently as possible. The region's focus on enhancing infrastructure resilience and promoting smart farming techniques is driving the growing demand for SCADA technologies in various sectors.

Chugoku Region SCADA Market Trends:

The Chugoku region, including Hiroshima, is focused on integrating SCADA technology in its manufacturing and power sectors. Notably, these systems are utilized in steel manufacturing plants to optimize production lines. The region is also incorporating these systems to support power generation and distribution, reflecting a push towards improving industrial processes and achieving operational efficiency in critical sectors.

Hokkaido Region SCADA Market Trends:

In Hokkaido, renewable energy and agriculture are driving the deployment of SCADA systems. In parallel, this system is used for environmental monitoring and precision farming driven by vast agricultural land. These solutions, for example, are used by agricultural firms in the region to monitor and control irrigation systems, further increasing crop production. Moreover, the region is focusing on SCADA for monitoring remote wind and hydroelectric power plants, helping manage energy distribution efficiently. This integration supports Hokkaido’s move towards greater automation and energy independence.

Shikoku Region SCADA Market Trends:

The use of SCADA in the food processing and water management industries is impelling the growth in the Shikoku region. At the same time, the food sector uses these systems to enhance quality control and production lines. For example, companies in Takamatsu are implementing SCADA for monitoring temperature and humidity during food processing to ensure product consistency. Additionally, Shikoku’s focus on water management systems is driving the demand for these solutions to enhance the efficiency of water distribution and wastewater treatment operations across the region.

Top Companies Leading in the Japan SCADA Industry

The market research report presents a complete study of the competitive landscape in Japan’s SCADA market, as the market is significantly evolving. Also, this report covers market structure, positioning of key players, detailed company profiles, etc. Aligned with these trends, in October 2023, Azbil Corporation partnered with X1Studio to strengthen the SCADA market in Japan. This collaboration combines X1Studio’s SCADA engineering expertise for data centers with Azbil’s building automation solutions, managing the growing demand for advanced SCADA systems. Besides, the alliance is poised to propel market development and invention, further improving the SCADA industry in Japan.

Japan SCADA Market Segmentation Coverage

- On the basis of the component, the market has been bifurcated into programmable logic controller (PLC), remote terminal units (RTU), human machine interface (HMI), communication systems, and others. SCADA systems integrate these components for real-time monitoring and control. Also, they ensure seamless data flow, enabling efficient process management and system automation across various industries.

- Based on the architecture, the market is categorized into hardware, software, and services. Hardware components such as PLCs and RTUs interface with software for data analysis and visualization, while services ensure system installation, maintenance, and optimization for operational efficiency and security.

- On the basis of the end user, the market has been divided into oil and gas, power, water and wastewater, manufacturing, chemicals and petrochemicals, pharmaceutical, and others. SCADA systems are vital across these industries to ensure efficient monitoring, control, and data management, optimizing production, ensuring safety, reducing costs, and improving operational reliability in diverse industrial environments.

| Report Features | Details |

|---|---|

| Market Size in 2024 | USD 1.3 Billion |

| Market Forecast in 2033 | USD 2.9 Billion |

| Market Growth Rate 2025-2033 | 9.23% |

| Units | Billion USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Components Covered | Programmable Logic Controller (PLC), Remote Terminal Units (RTU), Human Machine Interface (HMI), Communication Systems, Others |

| Architectures Covered | Hardware, Software, Services |

| End Users Covered | Oil and Gas, Power, Water and Wastewater, Manufacturing, Chemicals and Petrochemicals, Pharmaceutical, Others |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Browse IMARC Related Reports on SCADA Market:

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Inquire Before Buying

Inquire Before Buying

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

.webp)

.webp)