Global Methanol Market Expected to Reach USD 56.2 Billion by 2033, China Led with 47.8% Market Share in 2024 - IMARC Group

Global Methanol Market Statistics, Outlook and Regional Analysis 2025-2033

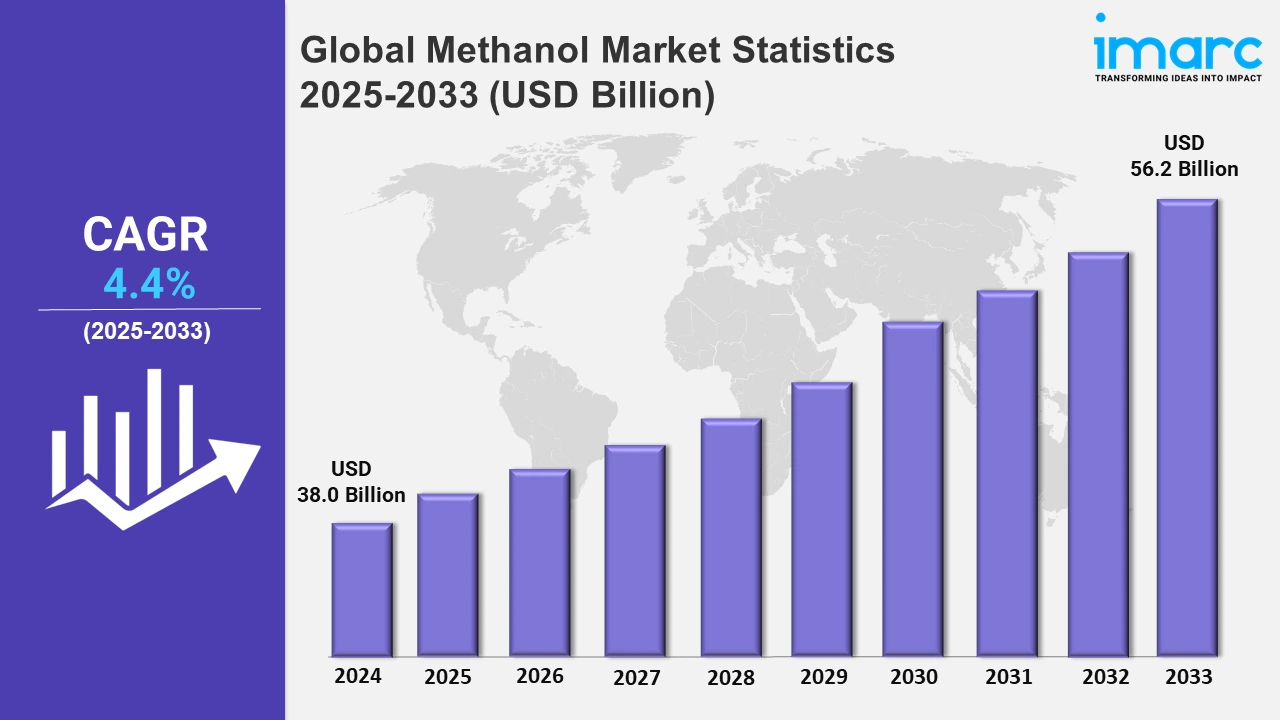

The global methanol market size was valued at USD 38.0 Billion in 2024, and it is expected to reach USD 56.2 Billion by 2033, exhibiting a growth rate (CAGR) of 4.4% from 2025 to 2033.

To get more information on this market, Request Sample

Technological advancements are improving the methanol production processes and enhancing its applications, thereby impelling the market growth. Innovations in catalytic processes and modern reactors are making methanol production more efficient and cost-effective. Besides this, the integration of digital technologies like automation, artificial intelligence (AI), and machine learning (ML) in methanol production facilities is increasing operational efficiency, reducing waste, and optimizing energy use. These improvements lead to higher-quality methanol and greater yield, which is beneficial for industries that rely on methanol as a key raw material. Moreover, key industry players are integrating these innovations to expand their marketspace. For example, in September 2024, ZF Group, a well-known technology company collaborated with Farizon, the leading producer of electric commercial vehicles to develop its cutting-edge range of new energy intelligent trucks with methanol-hydrogen technology. This accord emphasizes innovative solutions for enhancing truck-trailer safety and improving intelligence.

The rising adoption of sustainable practices, with industries and government agencies seeking cleaner and more environment friendly alternatives to traditional fuels and chemicals, is fueling the market growth. Methanol is considered a greener fuel option and thus is being employed in various sectors, especially in transportation and energy. It can be produced from renewable sources like biomass and carbon dioxide (CO2), contributing to a reduction in carbon emissions. This aligns with worldwide efforts to shift toward sustainable energy solutions and less dependency on fossil fuels. Apart from this, methanol is used in the production of bio-based chemicals and plastics. It serves as a feedstock for producing formaldehyde, acetic acid, and other chemicals, which are essential for manufacturing sustainable products in industries like automotive, construction, and textiles. In December 2024, the Methanol Institute (MI), a trade association for the methanol industry and Bia Energy Operating Company LLC, the innovative technology services provider joined hands to develop a modern low-carbon methanol production facility in Shreveport, Louisiana, with the vision to achieve more than 93% reduction in CO₂ emissions. Sustainable efforts like these are also contributing to the market growth.

Global Methanol Market Statistics, By Region

The market research report has also provided a comprehensive analysis of all the major regional markets, which include China, Asia-Pacific (excluding China), Europe, North America, Latin America, and Middle East and Africa. According to the report, China accounts for the largest market share driven by rising investments in methanol production, increasing adoption of methanol as a fuel, and high demand for construction materials.

China Methanol Market Trends:

China is enjoying the leading position in the market due to the increasing demand for chemicals like formaldehyde, acetic acid, and olefins. China’s methanol-to-olefins (MTO) technology is completely restructuring the petrochemical sector by ensuring that the need for necessary materials like methanol used in the production of plastics, and resins is met. Additionally, government agencies’ policies that support renewable energy and environmental sustainability are encouraging its utilization. Besides this, key market companies focus on energy efficiency and cleaner fuels, which promotes the use of methanol in fuel blending. For instance, China Tianying, a leading clean energy and recycling company made an announcement about its partnership with Icelandic firm Carbon Recycling International (CRI), a limited liability company to build synthetic methanol production plants by 2025. The initiative, based in Liaoyuan city, will employ CRI's emissions-to-liquids (ETL) technology to transform green hydrogen and captured biogenic CO2 into synthetic methanol.

Asia-Pacific (Excluding China) Methanol Market Trends:

The market for methanol in the Asia-Pacific (excluding China) region is characterized by its rising demand, particularly in India, Japan, and South Korea. In the region, companies employ methanol in fuel production, resins, and adhesives. Apart from this, they adopt methanol in energy uses, such as methanol-to-gasoline (MTG) and renewable sources of production.

Europe Methanol Market Trends:

The market for methanol is expanding gradually in Europe, which can be attributed to its high demand for chemicals, especially in industries like automotive, construction, and energy. Here, methanol is predominantly utilized to create formaldehyde and acetic acid, which are essential components in the production of items like plastics, paints, and textiles. In addition to this, the area highlights sustainable methods and the adoption of cleaner energy sources to generate demand for bio-methanol, a renewable option.

North America Methanol Market Trends:

North America accounts for a sizeable portion of the methanol industry owing to its rising usage in chemicals, energy, and fuel applications. The region’s ample natural gas reserves contribute significantly to methanol production, making it a cost-effective feedstock for manufacturing various products, such as plastics and resins. In this area, there is high adoption of methanol as an alternative marine fuel and a cleaner energy source for power generation.

Latin America Methanol Market Trends:

On account of the increasing demand for methanol-based chemicals, Latin America is experiencing methanol market expansion. For the most part, companies in Brazil and Mexico produce chemicals, materials, marine oils, and wind power with methanol. In addition to this, the Latin American region has large natural gas reserves which act as a secure and economical way to produce the chemical.

Middle East and Africa Methanol Market Trends:

The market for methanol in the Middle East and Africa region is distinguished by its large-scale natural gas reserves. Countries in the Middle East, particularly Saudi Arabia, Iran, and Qatar rely heavily on methanol for petrochemical production, especially in the manufacturing of plastics, resins, and other industrial chemicals. In the region, companies prefer methanol to develop clean energy solutions.

Top Companies Leading in the Methanol Industry

Key players are focusing on ensuring a steady supply of methanol to meet its rising demand. These companies are investing in advanced technologies for methanol production, such as methanol-to-olefins (MTO) and MTG, which are vital in the petrochemical and automotive sectors. Besides this, they are focusing on more sustainable production methods, such as bio-methanol and renewable methanol, contributing to the green energy transition. They are also partnering with government agencies, research and development (R&D) institutions, and industry stakeholders to explore new applications of methanol in cleaner fuels, energy storage, and carbon capture, ensuring its role in meeting sustainability goals. For instance, in January 2024, Maersk, the leading logistics company, introduced its new methanol-powered container ship, Ane Maersk, which will set sail from South Korea by February. Under the vision of green fuel for 25% of the transported volume by 2030, the company intends to lower emissions.

Global Methanol Market Segmentation Coverage

- On the basis of the application, the market has been categorized into formaldehyde, dimethyl ether, gasoline, chloromethane, MTBE/TAME, acetic acid, and others, wherein formaldehyde represents the leading segment. Formaldehyde is produced from methanol and is a key raw material in manufacturing products like plywood, particleboard, and fiberboard. Moreover, it is used as a disinfectant, a sterilizing agent, and a preservative in medical and research environments. It is also a very important medium for the production of assistive fuel additives like hexamine, which in turn, is commonly used both as solid fuel and fuel stabilizer in fuel.

| Report Features | Details |

|---|---|

| Market Size in 2024 | USD 38.0 Billion |

| Market Forecast in 2033 | USD 56.2 Billion |

| Market Growth Rate 2025-2033 | 4.4% |

| Units | Billion USD, Million Tons |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Applications Covered | Formaldehyde, Dimethyl ether, Gasoline, Chloromethane, MTBE/TAME, Acetic acid, Others |

| Regions Covered | China, Asia-Pacific (excluding China), Europe, North America, Latin America, Middle East and Africa |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Browse IMARC Related Reports on Methanol Market:

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Inquire Before Buying

Inquire Before Buying

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

.webp)

.webp)