Biomass Briquettes Manufacturing Cost Analysis: Shaping the Future of Solid Biofuels

What is Biomass Briquettes?

Biomass briquettes are dense, solid fuel blocks made of compressed organic waste materials like sawdust, agricultural wastes, wood shavings, coconut shells, rice husk, or herbaceous biomass. The briquetting process usually involves drying the biomass to lower the moisture content (usually down to 10-15%), grinding or milling for a fine particle size uniformity, and then compressing under high pressure with or without a binding agent. The lignin present in wood naturally or incorporated biomass binders assist in gluing the particles together when subjected to heat and pressure to create compact, cylindrical or rectangular briquettes.

Key Applications Across Industries:

The generated briquettes possess increased energy density, reduced transport and storage costs, and yield more consistent combustion and reduced emissions compared to loose biomass. Biomass briquettes are a multi-purpose substitute for coal, firewood, charcoal, and other fossil fuels in domestic heating, industrial boilers, brick kilns, and small power production. In rural settings, they make cleaner cooking fuel and ease deforestation pressure. Their uniformity of size and low water content render them suitable for mechanized combustion systems, promoting automation and enhanced thermal efficiency. Also, briquettes are eco-friendly: waste biomass utilization reduces landfill demand, decreases carbon emissions (because biomass is carbon-balanced on a lifecycle cycle), and assists in the disposal of agricultural waste. With more focus around the world on renewable energy and cleaner burning fuels, biomass briquettes are playing an increasingly significant role in the sustainable energy mix, particularly in developing nations with plenty of biomass and in areas with policies or incentives for biomass energy use.

What the Expert Says: Market Overview & Growth Drivers

The global biomass briquettes market reached a value of USD 1.03 Billion in 2024. According to IMARC Group, the market is projected to reach USD 2.17 Billion by 2033, at a projected CAGR of 8.10% during 2025-2033. Several important global drivers are propelling rising demand and investment in biomass briquettes.

In the first place, pressure on energy costs and fossil fuel price volatility are necessitating industry and consumers look towards cheaper renewable substitutes; biomass briquettes provide an affordable alternative particularly where locally available biomass feedstock are nearby. Second, climate change legislation and carbon reduction goals are driving governments to develop renewable and cleaner-burning fuels; briquettes have lower particulates and CO2 emissions than many fossil fuels, which aligns with national renewable energy and air pollution reduction strategies. Third, surplus agricultural and forestry residues in much of the emerging world are an accessible feedstock, converting what would otherwise be the cost of waste disposal or environmental liabilities into productive fuel assets. Fourth, clean cooking and rural electrification projects in Asia, Africa, and Latin America are growing demand for cleaner biomass fuels more advanced than traditional open firewood or charcoal, driving adoption at the grassroots level. Fifth, technological developments in briquetting machines lower capital expenditures, improved durability, modular designs are reducing entry obstacles for small- and medium-scale producers. Lastly, supportive policies like subsidies, tax credits, feed-in tariffs or renewable portfolio standards, biomass co-firing mandates in industries or power facilities are making the business cases for biomass briquette business more attractive. Export markets (for briquettes and pellets) also enjoy increased demand in developed countries due to sustainability certifications. In total, the combination of economic, environmental, technological, and regulatory drivers is compelling the biomass briquette market towards strong growth worldwide.

Case Study on Cost Model of Biomass Briquettes Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale biomass briquettes manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed biomass briquettes manufacturing plant in India. This plant is designed to produce 25,000 tons of biomass briquettes annually.

Manufacturing Process: The manufacturing process of biomass briquettes entails the conversion of loose biomass materials like sawdust, agricultural residues, rice husks, sugarcane bagasse, and wood shavings to energy-dense, compact briquettes via mechanical compression. Production starts with raw material collection and preparation, where agricultural and forestry wastes are collected and screened to eliminate impurities like stones, metals, and sand. This is followed by drying, a crucial step that lowers the water content of the biomass to an optimal value between 8–12%, as excess water inhibits briquette quality and combustion efficiency. The dried biomass is thereafter sized using hammer mills or crushers to get a uniform particle size, typically below 5 mm, so as to have consistent briquette formation. After proper drying and milling of the material, it is introduced into a briquetting press, which compresses it under high pressure, usually between 100 and 200 MPa without the use of any external binder. The inherent lignin content in the biomass melts with heat produced due to friction and pressure and serves as a natural binding agent holding the particles together. Depending on the machine model (piston press, screw extruder, or hydraulic press), the briquettes can be cylindrical, hexagonal, or rectangular. The briquettes are cooled and hardened in atmospheric conditions following extrusion to acquire mechanical stability. They are then screened, packed, and stored in dry conditions to avoid moisture absorption. This process produces a consistent, high-density fuel with efficient combustion, minimal emissions, and simpler transportation and handling compared to raw biomass.

Get a Tailored Feasibility Report for Your Project Request Sample

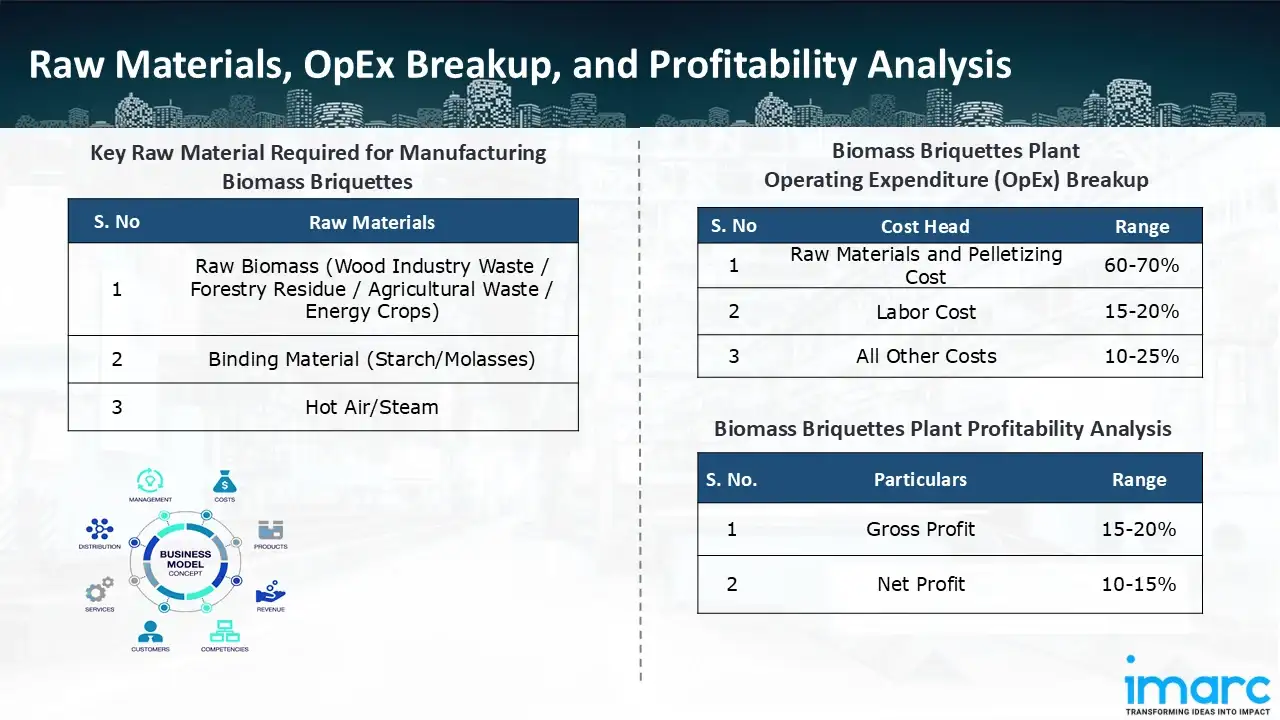

Raw Material Required:

The basic raw materials required for biomass briquettes manufacturing include:

- Raw Biomass (Wood Industry Waste / Forestry Residue / Agricultural Waste / Energy Crops)

- Binding Material (Starch/Molasses)

- Hot Air/Steam

Machineries Required:

- Conveyor Belt

- Storage System

- Rotary Screen

- Screw Conveyor

- Hammer Mill

- Woodchipper

- Grinder

- Binder Mixing Unit

- Rotary Drum Dryer

- Belt Dryer

- Flash Dryer

- Buffer Bin

- Variable Speed Feeding Screw Conveyor

- Screw Extruder

- Briquette Press (Screw Press, Hydraulic Press, or Piston/Stamping Press)

- Discharging Belt

- Pellets Surge Bin

- Air Conveying System

- Cyclone Dust Collector

- Air Cooler

- Rotary Cooler

- Carbonization Furnace

- Quality Testing Machine

- Electronic Control System

- Automatic Briquette Packaging

- Labeling Machine

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material and pelletizing cost in a biomass briquettes manufacturing plant ranges between 60-70%, labor cost ranges between 15% to 20%, and all other costs ranges between 10-25% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 15-20%, and net profit lie between the range of 10-15% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the biomass briquettes manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 25,000 tons of biomass briquettes annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In January 2025, Piramal Pharma's production plant in Digwal, India, has switched from a coal-fired steam boiler to one that runs on biomass. According to the corporation, the planned conversion at the Digwal factory will remove nearly 24,000 tonnes of carbon dioxide equivalent (tCO2e) greenhouse gas emissions per year, or roughly 17% of the company's overall emissions. A significant step forward in Piramal's sustainability path is the adoption of biomass briquettes.

- In April 2024, Vedanta Aluminium, has begun using a more environmentally friendly fuel mix made of biomass briquettes for renewable energy at its top-notch alumina refinery in Lanjigarh, Odisha. 20 tonnes of the new fuel mix are currently used daily by the corporation, which is a major step towards reaching Net Zero Carbon by 2050 or earlier.

- In February 2024, a division of EKI Energy Services, GHG Reduction Technologies, announced the opening of a cutting-edge Biomass Briquettes (Biocoal) production facility in Dindori, Nashik, Maharashtra. GHG Reduction Technology's continued dedication to clean energy transitions and reducing global warming reached a major turning point with the inaugural event.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104