Electro-Efficiency: Economics Behind Electric Vehicle Production Costs

_11zon.webp)

What is Electric Vehicle?

Electric Vehicles, or EVs, are vehicles operated partially or wholly by electrical power, generally with rechargeable battery packs as their fuel. In contrast to conventional internal combustion engine cars, EVs emit no tailpipe emissions, making them a cleaner, environmentally friendly transportation choice.

Key Applications Across Industries:

EVs comprise Battery Electric Vehicles (BEVs), Plug-in Hybrid Electric Vehicles (PHEVs), and Hybrid Electric Vehicles (HEVs), and are gaining ground in passenger, commercial, and two-wheeler segments owing to developments in battery technology, charging infrastructure, and policy support.

What the Expert Says: Market Overview & Growth Drivers

According to an IMARC study, the global electric vehicle market reached USD 755 Billion in 2024. Looking ahead, the market is expected to grow at a CAGR of 21.5% from 2025 to 2033, reaching a projected size of USD 4,360 Billion by 2033.

The global electric vehicle (EV) market is growing with strong momentum, driven by a mix of regulatory, technology, economic, and consumer factors. One of the key drivers is the increasing focus on environmental sustainability that has caused governments worldwide to introduce tough emission controls and climate policies, like having net-zero carbon emissions by 2050. These policies have given a tremendous boost to financial incentives, including subsidies, tax breaks, and rebates at the time of purchasing EVs, that keep the overall cost of ownership down for buyers. At the same time, the price of lithium-ion batteries, the most key element in EVs has declined sharply in the last ten years as a result of economies of scale and technological innovation, making EVs increasingly cost-competitive with ICE vehicles. The development of EV charging infrastructure in the form of ultra-fast charging and home charging is also reducing range anxiety and promotes adoption. In addition, the fluctuating and increasing prices of fossil fuels, along with increased consumer consciousness regarding environmental concerns, are favoring sustainable mobility solutions. Urbanization, growing disposable income, and growing penetration of EVs in emerging markets also underpin the global expansion of the electric vehicle market.

Case Study on Cost Model of Electric Vehicle Manufacturing Plant

Objective

One of our clients has approached us to conduct a feasibility study for establishing a mid to large-scale electric vehicle production plant in United States.

IMARC Approach: Comprehensive Financial Feasibility

We have developed a detailed financial model for the plant's set-up and operations. The proposed facility is designed with an annual production capacity of 100,000 units of electric vehicle.

Manufacturing Process: The production process of an electric vehicle (EV) comprises a number of critical steps, combining conventional auto assembly with sophisticated electrical systems. It starts with vehicle design and engineering, such as battery configuration, motor layout, and chassis structure. Then comes battery pack manufacturing, where lithium-ion cells are placed into modules and packaged into a battery pack with cooling and safety features. At the same time, electric motors and power electronics like inverters and controllers are produced. At the vehicle assembly line, the body and frame are built and painted, and subsequently components such as the electric drivetrain, battery pack, motor, suspension, and brakes are fitted. The wiring harness and control units are also fitted to control vehicle functions. Interior trim such as seats, infotainment systems, and dashboards are included subsequently. After assembly, the car goes through quality checking and software calibration, such as charging tests, range checks, and diagnostics. Every EV is then put through road and safety tests prior to final inspection and delivery. The EV manufacturing process is highly mechanized and ecologically oriented, with priorities placed on light materials, environmentally friendly practices, and energy efficiency during production.

_11zon.webp)

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials utilized in the electric vehicle production plant largely include electric motor, battery pack, Battery Management System (BMS), onboard charger, inverter, regenerative braking system, thermal management system, power electronics controller, charging port, cabin heating and cooling, control unit, drive train, auxiliary battery, chassis and body, suspension system, infotainment and connectivity, safety systems and wheels and tires. To produce 1 unit of electric vehicle, 1 unit of each of these components are required.

List of Machinery:

The following line of equipment was required for the proposed plant:

- Conveyor and Inspection Line

- Painting Line

- Testing Line

- 6 Axis Robot Arm Line

- Power Press Line

- Screw Air Compressor

- Hot Pressing Edge Conveing Equipment

- TAIL ROBOT LASER Cutting & OPENING equipment

- Hot plate welding equipment

- Hot riveting welding equipment

- Bumper stamping and welding equipment

- Double robot turntable type-wheel eyebrow welding equipment

- Ultrasonic special machine for luggage side panels

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

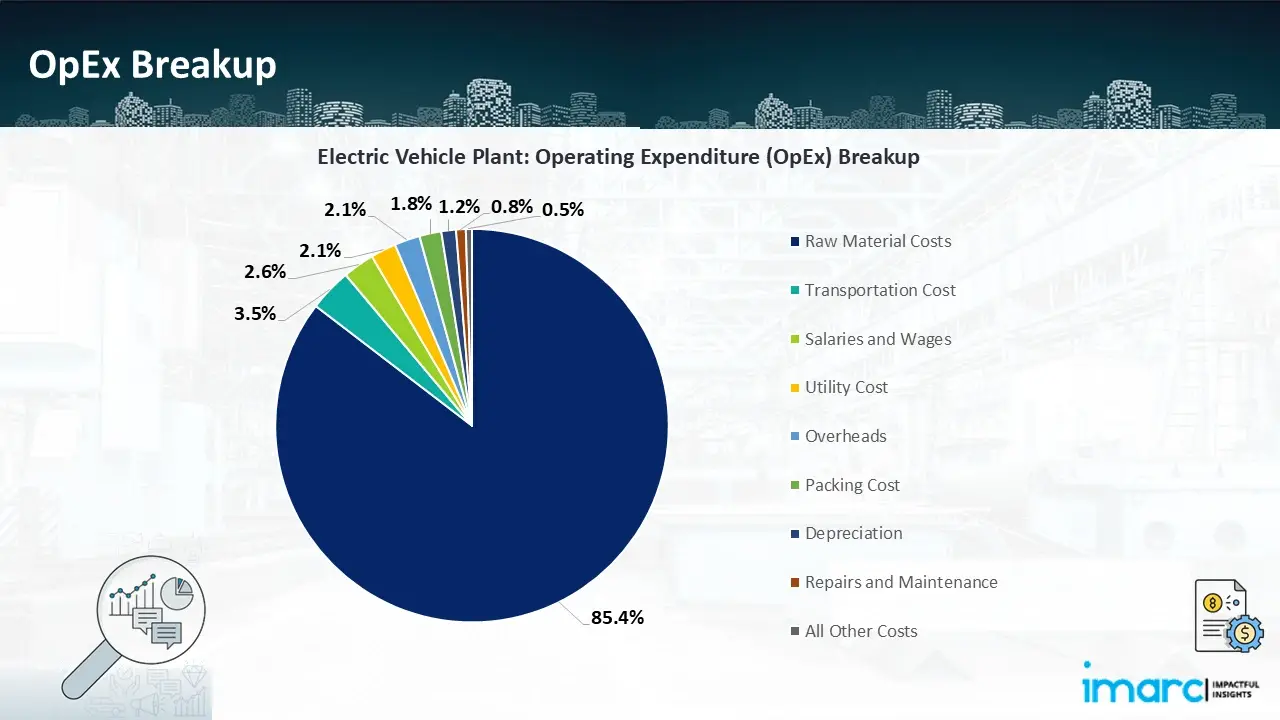

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

-

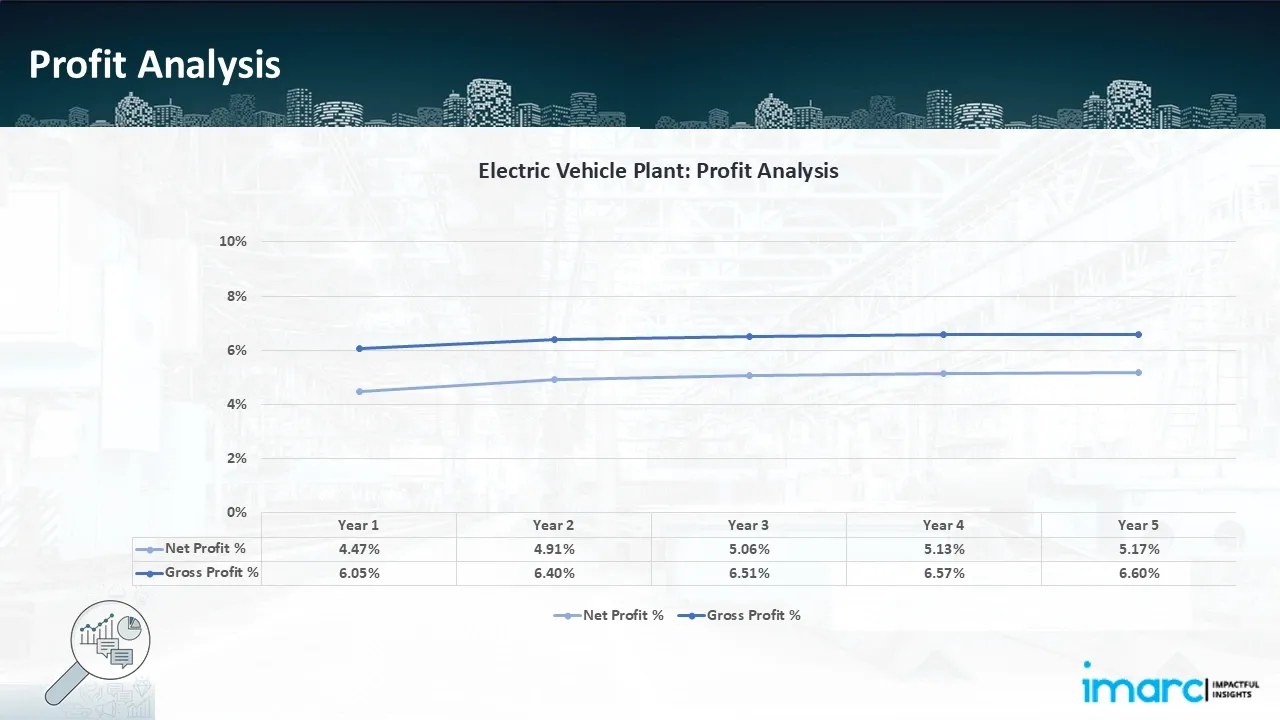

Profitability Analysis Year on Year Basis: The proposed electric vehicle plant, with an annual capacity of 100,000 units of electric vehicle, achieved an impressive revenue of US$ 1.08 billion in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins improves from 6.05% to 6.60% by year 5, and net profit rises from 4.47% to 5.17%, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our electric vehicle manufacturing plant's financial model was meticulously modelled to satisfy the client's requirements. It provided a thorough analysis of production costs including capital expenditures, manufacturing processes, raw materials, and operating costs. The model predicts profitability while accounting for market trends, inflation, and any shifts in the price of raw materials. It was created especially to satisfy the demand for producing 100,000 units of electric vehicle annually. Our commitment to offering precise, client-cantered solutions that ensure the long-term success of significant industrial projects by giving the client useful data for strategic decision-making is demonstrated by this comprehensive financial model.

Latest News and Developments:

- In July 2025, VinFast, a Vietnamese electric car manufacturer, started production on Sunday at its second local plant with the goal of increasing manufacturing of reasonably priced micro urban models as its plans for international development are delayed. The new factory, which is 36 hectares (90 acres) in size and is situated in the central province of Ha Tinh, can initially produce 200,000 units annually.

- In April 2025, the British supercar manufacturer McLaren Automotive is about to embark on a daring new chapter under new ownership with the merger of EV startup Forseven Holdings. Following the acquisition of McLaren Automotive by Abu Dhabi-based investment group CYVN Holdings, which as part of the agreement added a minority, non-controlling position in the McLaren Formula 1 team to its portfolio.

- In July 2024, BYD opened its first fully owned plant outside of China in Rayong, Thailand. With 10,000 workers, the plant can produce 150k EVs a year. Another $1 billion facility with a 150k capacity is being built by BYD in Subang, Indonesia; it was originally planned to begin construction in late 2025 but is now expected to begin in late 2025.

- In October 2024, the merger between Vitesco Technologies Group AG ("Vitesco") and Schaeffler AG ("Schaeffler"), which was announced over a year ago, has been successfully completed. Today, Vitesco and Schaeffler merged after the combination was finally recorded in Schaeffler's commercial register.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Brief List of Our Services: Market Entry and Expansion

- Market Entry and Opportunity Assessment

- Competitive Intelligence and Benchmarking

- Procurement Research

- Pricing and Cost Research

- Sourcing

- Distribution Partner Identification

- Contract Manufacturer Identification

- Regulatory Approvals, and Licensing

- Factory Setup

- Factory Auditing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104