ERW Steel Pipes Cost Model: Seamless Efficiency

What is ERW Steel Pipes?

ERW steel pipes can be identified as one of the most important categories of welded pipes and find wide applications in infrastructure, construction, and other industries because of their precision, cost-effectiveness, and reliability. The raw material to produce these pipes is either hot-rolled or cold-rolled steel coils that are longitudinally formed and welded by the application of high-frequency electric resistance welding.

Key Applications Across Industries:

Unlike seamless pipes, which are made by extrusion or rotary piercing, ERW pipes are made by continuously shaping flat steel strips into cylindrical shapes and welding the edges under heat and pressure without using filler material. This gives them uniform wall thickness, a smooth finish, and great mechanical properties; hence, they are applied in services related to low and medium pressure, such as water, oil, gas, and structural purposes. The diameters and wall thickness of ERW steel pipes come in a wide range for different end-use industries such as the automotive industry, building and construction, energy, and agriculture. The precision associated with the welding process and high-quality raw material input ensures superior dimensional accuracy, surface finish, and weld integrity. Advanced facilities used in the manufacture of modern ERW pipes include high-frequency induction, nondestructive testing, and automated quality inspection systems that ensure defect-free production of pipes. Further, ERW pipes are usually galvanized, coated, or internally lined to increase their resistance to corrosion and extend their lives in demanding operational environments. Their easy fabrication, lightweight, and adaptability to custom specifications have positioned ERW steel pipes as a preferred choice for structural, mechanical, and fluid-conveyance applications across global industries.

What the Expert Says: Market Overview & Growth Drivers

The global ERW steel pipes market reached a value of USD 19.70 Billion in 2024. According to IMARC Group, the market is projected to reach USD 31.50 Billion by 2033, at a projected CAGR of 5.4% during 2025-2033. The driving factors for the ERW steel pipes market are a mix of infrastructure expansion, industrialization, and technological innovation in the manufacturing of steel. Among these, expanding requirements for urban infrastructure and energy transportation systems around the world, especially for water supply, oil and gas transmission lines, and sewage networks, where ERW pipes are greatly used, present good opportunities for growth. In developing economies across Asia, Africa, and Latin America, investment in construction and urban housing and pipeline networks continues to drive demand for affordable and durable ERW pipes. The demand for ERW tubes is also increasing in the automotive and engineering sectors for making chassis, frames, and precision components owing to their uniformity, lightweight structure, and strength.

Another powerful growth factor is the technological development of manufacturing processes, especially the adoption of high-frequency induction welding, improved methods of non-destructive testing, and the automation of quality control systems. These developments have enhanced production efficiency, reduced defects, and widened the suitability of ERW pipes to higher pressure applications. The global focus on renewable energy and hydrogen infrastructure is creating other opportunities as manufacturers develop ERW pipes that will be able to handle hydrogen transport in high-corrosion environments. Furthermore, the trend of sustainability and recyclability in steel production favorably supports the application of ERW pipes, which can be made efficiently from recycled steel at lower energy intensities than seamless pipes. Government initiatives to strengthen local manufacturing, together with the extension of trade in steel products, also spur growth. As industries continue to demand suitable, cost-effective, and flexible piping solutions, the ERW steel pipe segment is likely to see continued growth worldwide, closing the gap between performance and affordability for the needs of modern engineering.

Case Study on Cost Model of ERW Steel Pipes Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale ERW steel pipes manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed ERW steel pipes manufacturing plant in India. This plant is designed to manufacture 24,000 tons of ERW steel pipes annually.

Manufacturing Process: Manufacturing ERW steel pipes involves a highly controlled and automated series to transform flat steel strips into strong, accurately welded tubular products. The process consists of raw material selection and preparation, which is generally in the form of hot-rolled or cold-rolled steel coils. First, uncoiling, levelling, and trimming are conducted to maintain consistent width and thickness. A steel strip, commonly called a skelp, is then fed onto a forming mill, where a series of contoured rollers gradually bends the flat strip in a circular configuration. This continuous forming ensures a uniform pipe diameter and wall thickness. When the edges of the formed strip meet, they are heated by high-frequency electric resistance (HFI) that raises the edge temperature to a near-melting point without any filler material. Under pressure, the heated edges forge together, forming a solid-state weld. Internally and externally, the excess flash metal produced during welding is removed to get a smooth surface. Then, the welded pipe goes through a sizing mill where it is precisely shaped and calibrated according to dimensional tolerances and roundness specifications. After forming and welding, the pipe undergoes heat treatment to relieve residual stresses and enhance mechanical properties. This is followed by non-destructive testing (NDT) methods such as ultrasonic or eddy-current inspection to detect any imperfections along the weld seam. The pipes are then cut to desired lengths, straightened, hydrostatically tested, and surface-treated through galvanizing or coating for corrosion protection. Finally, after rigorous quality inspection and certification, the ERW pipes are packaged and dispatched. This efficient, high-speed manufacturing process ensures strong weld integrity, uniformity, and cost-effectiveness, making ERW pipes ideal for structural, industrial, and fluid transport applications worldwide.

Get a Tailored Feasibility Report for Your Project Request Sample

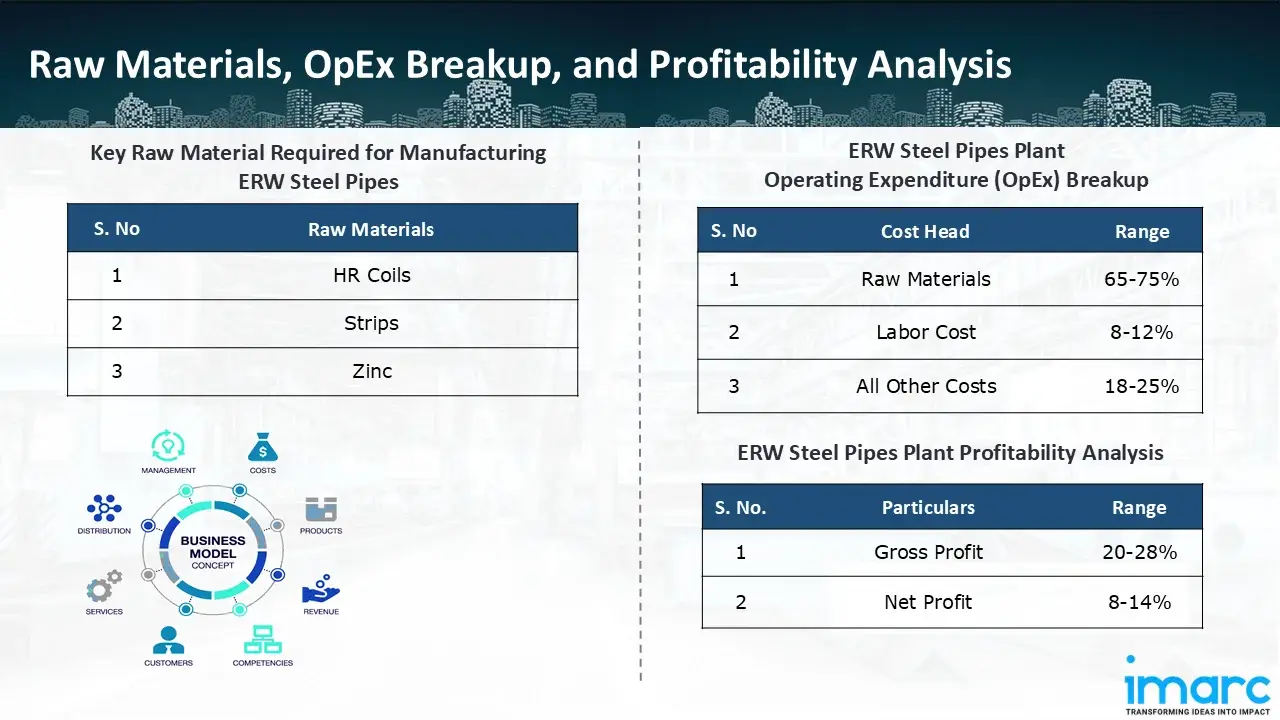

Raw Material Required:

The basic raw materials required for ERW steel pipes manufacturing include:

- HR Coils

- Strips

- Zinc

Machine Section or Lines Required:

- Uncoiler

- Forming Mill

- HF Welder

- Sizing

- Cutting

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in ERW steel pipes manufacturing plant ranges between 65-75%, labor cost ranges between 8% to 12%, and all other costs ranges between 18-25% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 20-28%, and net profit lie between the range of 8-14% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the ERW steel pipes manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 24,000 tons of ERW steel pipes annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This compreh ensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In July 2025, Grow Ever Steel (India) Private Limited, a manufacturer of ERW steel tubes and components, announced launching its fourth facility in Uluberia, West Bengal. The facility will commence its operations in September 2025.

- In July 2025, JTL Industries announced a significant capacity expansion initiative with the planned commissioning of a new Electric Resistance Welded (ERW) pipe manufacturing line, specifically targeted to serve the ASTM/API-grade pipe market. This project will boost JTL's leadership in the value-added and high-strength steel pipe segments by adding a significant yearly capacity of 3,00,000 MTPA.

- In August 2024, Tata Steel and Welspun Corp became the first Indian companies to produce Electric Resistance Welded (ERW) pipes for transportation of gaseous hydrogen. In 2022, Tata Steel and Welspun Corp. signed an MOU to create API X65 H grade pipes that are compatible with hydrogen regulations using the ERW Pipe method.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104