Fertilizer Cost Model: Feeding the Fields

A fertilizer is any natural or manufactured material containing one or more nutrients that are applied to the soil or plant tissues and that are usually beneficial for plant growth by improving fertility. The elements that plants need in large quantities, namely nitrogen (N), phosphorus (P), and potassium (K), are known as the primary macronutrients. The other secondary nutrients include calcium, magnesium, and sulfur; micronutrients include zinc, iron, manganese, and copper. Fertilizers can be broadly classified into organic and inorganic types. Organic fertilizers may be compost, manure, and bone meal, whereas inorganic fertilizers are of chemical origin and manufactured through a chemical process, often starting with ammonia synthesis and mining of minerals. The most widely used inorganic fertilizers are urea, ammonium nitrate, DAP, and MOP. The manufacturing of fertilizers involves complicated industrial processes, such as the Haber-Bosch process for ammonia production, nitric acid synthesis, and phosphoric acid processing in the case of phosphate fertilizers. Modern fertilizers are mostly tailor-made formulations to meet specific soil conditions, crop requirements, and environmental standards. Advanced products include slow-release and nano-fertilizers that help in optimizing nutrient delivery and reducing losses to the environment. Fertilizers play a very important role in global food security due to their contribution to the immense increase in crop yield, nutrient efficiency, and soil productivity. In fact, they have played an instrumental role in supporting the agricultural revolutions that have been sustaining the modern food systems. With the global demand for food continuing to rise along with population growth, fertilizers remain indispensable for sustainable and efficient agricultural production across various climatic and soil conditions. The global fertilizer market reached a value of USD 187.9 Billion in 2025. According to IMARC Group, the market is projected to reach USD 248.0 Billion by 2034, at a projected CAGR of 3.04% during 2026-2034. The global fertilizer market is driven by a combination of demographic, agricultural, environmental, and technological factors that continue to shape modern farming practices. One of the main driving factors is the rising population of the world, thus increasing food demand and, subsequently, the requirement to improve crop yield in limited arable land areas. Fertilizers are basically applied to improve soil nutrient content for high-yield crops and to maintain agricultural sustainability, particularly on lands with depleted or low-fertility soils. Rapid urbanization and industrialization have indeed further reduced the cultivable land, consequently forcing farmers to rely on fertilizers for higher per-hectare yield with better soil health. Other critical drivers are the trend toward precision and sustainable agriculture, wherein the farmers use controlled-release, bio-based, and micronutrient-enriched fertilizers to optimize the use of resources while minimizing negative impacts on the environment. Integration of digital agriculture, soil testing technologies, and smart nutrient management systems is modernizing application methods, enhancing efficiency, and consequently reducing runoff losses. Government policies and subsidy programs for agriculture in major agricultural economies like India, China, and Brazil promote the adoption of fertilizers by guaranteeing price stability and ensuring that farmers have access to vital inputs. The increasing awareness of soil degradation and nutrient imbalance has also spurred demand for specialty fertilizers, including water-soluble and foliar formulations, tailored for high-value horticultural and greenhouse crops. Furthermore, the emergence of green ammonia and low-carbon fertilizer technologies is reshaping the industry's sustainability profile, aligning with global decarbonization goals. These combined trends-driven by the pursuit of higher yields, environmental responsibility, and technological advancement-are ensuring the fertilizer industry's continued evolution as a cornerstone of global agricultural productivity and food security.

Trending Insights on Fertilizer: Latest News and Developments

- In July 2025, the Mosaic Company declared that it will start operations this month at its new blending, storage, and distribution facility in Palmeirante, Tocantins, Brazil. The factory boosts blending capacity and strengthens Mosaic's market share in Brazil's rapidly expanding northern region. Mosaic's ambitious growth plans in Brazil will be greatly aided by the Palmeirante facility, which has the potential to process 1 million tonnes of fertiliser annually and roughly 500,000 tonnes in 2025.

- In April 2025, CF Industries Holdings, Inc. announced that it has formed a joint venture with JERA Co., Inc., and Mitsui & Co., Ltd. for the construction, production and offtake of low-carbon ammonia.

- In November 2024, PhosAgro announced its plans to invest a record RUB 75 billion by the end of the year and flagged large capex projects including sulphuric-acid and phosphogypsum conversion capacity increases through coming years.

Case Study on Cost Model of Fertilizer Manufacturing Plant:

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale fertilizer manufacturing plant. We developed a comprehensive financial model for the setup and operation of a proposed fertilizer manufacturing plant in India. This plant is designed to manufacture 50,000 tons of fertilizer annually.

Manufacturing Process: The manufacturing process of fertilizers encompasses various chemical, physical, and mechanical operations to transform raw feedstocks like natural gas, phosphate rock, potash, and sulfur into nutrient-rich compounds suitable for agricultural uses. The processes differ with the kind of fertilizer to be produced-nitrogenous, phosphatic, or potassic-but they all have one thing in common: making the nutrients more available to the plant. The production of nitrogen-based fertilizers begins with the Haber-Bosch process: under high temperature and pressure, nitrogen from the air reacts with hydrogen, generally obtained from natural gas, in the presence of a catalyst to yield ammonia, NH3. Ammonia is the building block for a number of fertilizers, such as urea, ammonium nitrate, and ammonium sulfate. In the manufacture of urea, ammonia is reacted with carbon dioxide in a series of steps to produce ammonium carbamate, which is dehydrated to yield urea granules or prills. For ammonium nitrate, ammonia is oxidized to nitric acid, which, in turn, is combined again with ammonia to provide the final product. In the case of phosphatic fertilizers, naturally occurring phosphate rock is treated with sulfuric acid or phosphoric acid to produce single or triple superphosphate, which is then granulated and dried. Similarly, potassic fertilizers are obtained by mining and purifying potash ores like sylvinite or carnallite, followed by crushing, flotation, and crystallization. Once the individual nutrient products are ready, they may be blended, granulated, coated, or fortified with micronutrients to form compound or specialty fertilizers. Throughout production, quality control ensures consistent nutrient concentration and granule size with a moisture content. The final product is then packed and distributed for use in agriculture to support efficient nutrient delivery and sustainable crop growth.

Get a Tailored Feasibility Report for Your Project Request Sample

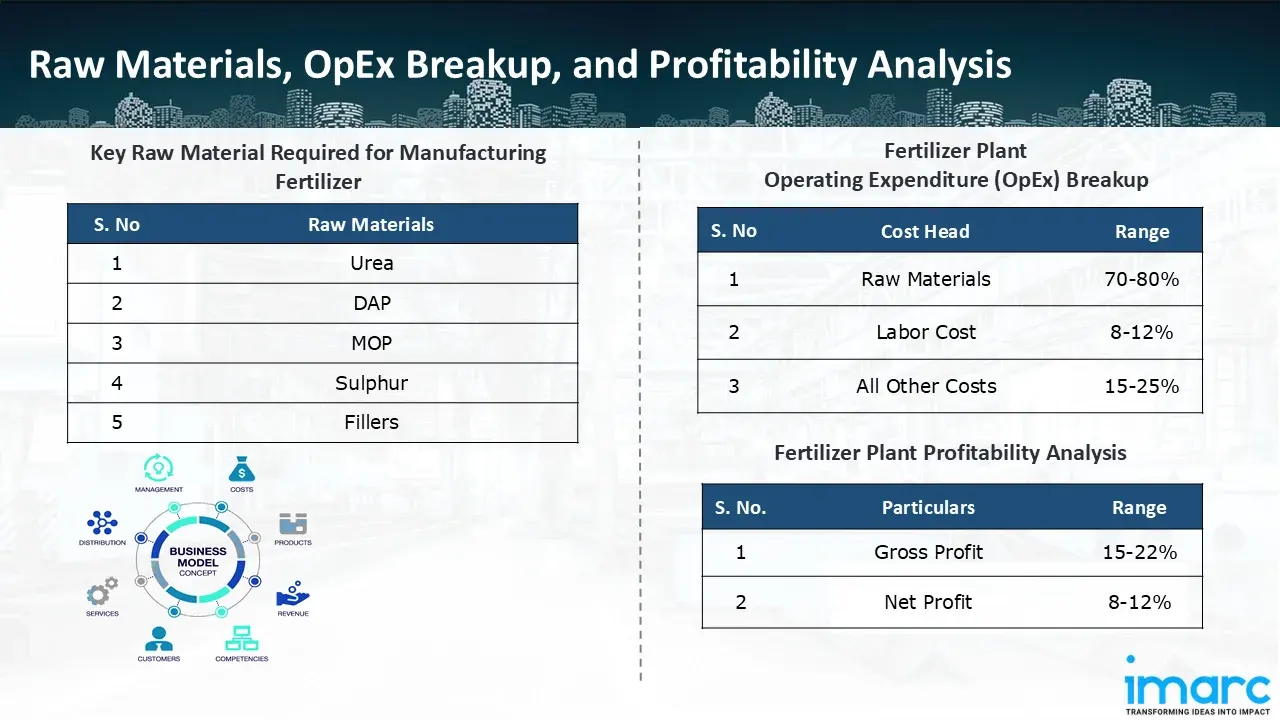

Raw Material Required:

The basic raw materials required for fertilizer manufacturing include:

- Urea

- DAP

- MOP

- Sulphur

- Fillers

Machine Section or Lines Required:

- Crushing

- Mixing

- Granulation

- Drying

- Screening

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in fertilizer manufacturing plant ranges between 70-80%, labor cost ranges between 8% to 12%, and all other costs ranges between 15-25% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 15-22%, and net profit lie between the range of 8-12% during the income projection years, highlighting strong financial viability and profitability.

Conclusion:

Our financial model for the Fertilizer manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 50,000 tons of fertilizer annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104