Setting Up Laptop and Tablet Production Plant: A Cost Model Analysis

_11zon.webp)

What is Laptop?

The global laptop and tablet market includes portable computing devices for both personal and commercial use, providing mobility, flexibility, and connectivity. Laptops extend desktop computers' power and functionality in a portable package, while tablets provide light-touch screen interfaces for consumption of media, creative work, and on-the-go productivity.

Key Applications Across Industries:

These products appeal to various user groups, such as students, commercial professionals, gamers, and light-users. Technological innovation has brought about advancements in the form of 2-in-1 hybrids, high-definition displays, improved processors, more battery life, and improved connectivity solutions. Competition is rampant in the market as top players innovate at every level, including design, performance, and price, to cater to changing consumers' needs.

What the Expert Says: Market Overview & Growth Drivers

The global laptop market reached USD 151.1 Billion in 2024. According to IMARC Group, the market is projected to reach USD 200.7 Billion by 2033, exhibiting a growth rate (CAGR) of 3.07% during 2025-2033.

The global market for laptops and tablets is fueled by increasing digitalization within industries, expanding remote work and e-learning adoption, and the growing demand for mobility alongside high-performance computing solutions. The education industry, especially in developing economies, is also experiencing healthy demand for cost-effective devices to facilitate online learning initiatives. The move of the corporate sector towards hybrid work models has fueled demand for high-performance laptops and tablets that are light in weight. Also, developments in 5G networks, cloud computing, and AI-based capabilities are strengthening device performance and user experiences. The emergence of creative experts and content creators is driving demand for better graphics devices, stylus-carrying devices, and multitasking capabilities. User desire for slim, super-thin products with extended battery life is shaping product innovation. Green sustainability trends are also compelling manufacturers to employ recyclable materials and energy-efficient parts, further increasing adoption and brand attractiveness.

Case Study on Cost Model of Laptop Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a large-scale laptop manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed laptop manufacturing plant in United States. This plant is designed to produce 300 laptops per day.

Manufacturing Process: Manufacturing laptops starts with designing, where engineers set specifications like material, looks, and essential parts like the motherboard, CPU, and memory—usually outsourced because of their complexity. In raw material buying, producers purchase key components like gold, glass, steel, polymers, and most notably purified silicon for CPUs, which is shaped into wafers for microprocessors and memory chips. Component production takes place in specialized manufacturing facilities, which create components like the CPU, circuit boards, and screens. They are assembled into dedicated factories, where technicians connect pieces, scan serial numbers for tracing, and fit together in a precise manner. Software installation with operating systems and preinstalled programs readies the device next. Testing is conducted, including boot-up verification and burn-in procedures to identify hardware or software flaws under sustained operation. Finally, after quality inspections, laptops are packaged with manuals and accessories, then dispatched worldwide, ensuring durability, performance, and readiness for end-users.

_11zon.webp)

_11zon.webp)

_11zon.webp)

Mass Balance and Raw Material Required: The primary raw materials used in the laptop manufacturing plant include bezel, LCD screen, LCD back cover, hinges, inverter board, inverter cable, camera, WI-fi antenna, speakers, keyboard, LED board cover, palm rest, touchpad board, LED board, CPU and VGA fan/ W heatsink, modem board, battery, main board, USB board cable, bottom cover, HDD cover, RAM cover, CPU, RAM, mini PCI wireless board, VGA board, Bluetooth board, HDD, optical driver and screw kit. For a plant producing 1 unit of laptop, 1 unit of bezel, 1 unit of LCD screen, 1 unit of LCD back cover, 1 unit of hinges, 1 unit of inverter board, 1 unit of inverter cable, 1 unit of camera,1 unit of WI-fi antenna, 4 units of 1 unit of speakers, 1 unit of keyboard, 1 unit of LED board cover, 1 unit of palm rest, 1 unit of touchpad board, 1 unit of LED board, 1 unit of CPU and VGA fan/ W heatsink, 1 unit of modem board, 1 unit of battery, 1 unit of main board, 1 unit of USB board cable, 1 unit of bottom cover, 1 unit of HDD cover, 1 unit of RAM cover, 1 unit of CPU,1 unit of RAM, 1 unit of mini PCI wireless board, 1 unit of VGA board, 1 unit of Bluetooth board, 1 unit of HDD, 1 unit of optical driver and 1 unit of screw kit are required.

Types of Machinery:

- Front End Lifter

- Back End Lifter

- Workstation 1.2m

- Labelling Machine

- Testing Machine

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

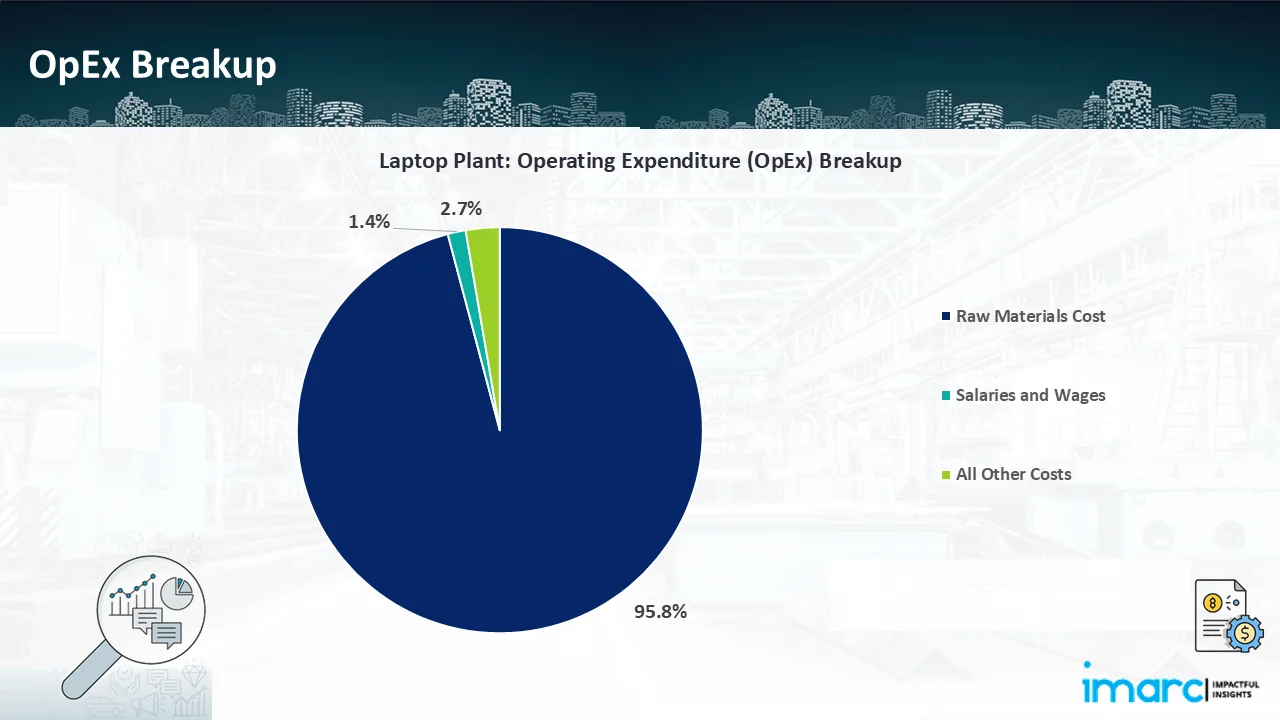

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

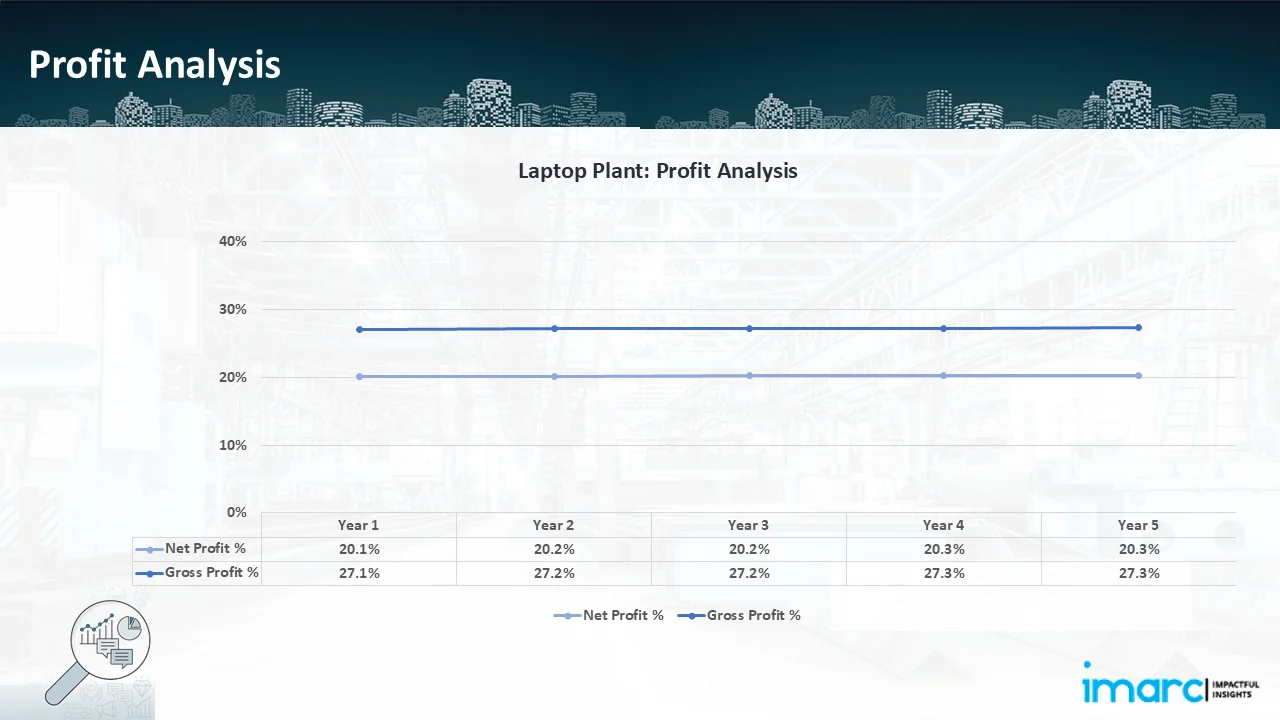

- Profitability Analysis Year on Year Basis: The proposed laptop plant, with a capacity of 300 laptops per day, achieved an impressive revenue of US$ 637.9 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins improves from 27.1% to 27.3%, and net profit rises from 20.1% to 20.3%, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the laptop manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of producing 300 laptops per day, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In March 2025, Apple unveils the new MacBook Air, a stunning new sky blue hue with the M4 chip's soaring performance.

- In May 2025, Microsoft and Surface added the 13-inch Surface Laptop and 12-inch Surface Pro to the Copilot+ PC family. These devices were made with portability and performance in mind. By making ultra-thin, lightweight, and powerful Copilot+ PCs available to more people at even lower price ranges, these new PCs represent the next wave of Surface innovation.

- In September 2024, HP Inc. and Dixon Technologies' subsidiary Padget Electronics have inked a Memorandum of Understanding (MoU) to produce HP laptops, personal computers, and all-in-one systems in Tamil Nadu, supporting India's Aatmanirbharta project. Union Information & Broadcasting Minister Ashwini Vaishnaw made the statement on Monday, emphasising the accomplishments of the "Make in India" campaign's Production Linked Incentive (PLI) program.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104