Paper Cups Manufacturing Cost Analysis: Sip-Worthy Margins

What are Paper Cups?

Paper cups are a type of beverage container made mostly from paperboard. The paperboard gives the container strength. The lining of the paperboard varies and usually consists of waterborne coatings, bio-based coatings, and polymer coatings. This facilitates the paper cup to hold hot and cold fluids for an amount of time. Paper cups come in various sizes and different wall structures. This makes the paper cup functional for the desired purpose and environment. Paper cups find their major usage as disposable packaging solutions. This comes together where convenience and the packaging meet.

Key Applications Across Industries:

Paper cups are widely used in the foodservice, catering, retail, institutional, and event sectors for the ease and hygiene offered by this packaging type. Paper cups are commonly used for the serving of hot beverages such as coffee, tea, and hot chocolates. Double-wall or insulated paper cups are designed for the purpose of providing protection to the consumer against heat. In the case of cold beverages, paper cups are used for the serving of soft drinks, juices, smoothies, iced coffee, and milk-based products.

Paper cups are also widely employed in institutional establishments such as hospitals, schools, office spaces, and transportation centers for regulated and hygienic beverage dispensing. The organization and management of events and catering services extensively utilize paper cups during large-scale events like exhibitions, festivals, and conferences. Paper cups are also utilized in vending machines and self-service beverage-dispensing machines.

In addition to drink containers, paper cups are also used in portioning foods like ice cream, soups, dessert foods, snacks, and condiments. Paper cups have a print-friendly property that enables companies to produce marketing messages or health messages, thus serving as a marketing tool for organizations that provide foods. Specialized paper cups are also utilized for sampling foods, new product offerings, and in-flight foods. In general, paper cups promote efficient service and cleanliness.

What the Expert Says: Market Overview & Growth Drivers

The global paper cups market reached a value of USD 7.02 Billion in 2024. According to IMARC Group, the market is projected to reach USD 9.10 Billion by 2033, at a projected CAGR of 2.9% during 2025-2033. The worldwide market for paper cups is driven by the growing foodservice sector, with other drivers including changes in consumer behavior, sustainable practices, and government policies against plastic packaging. Among the most significant drivers of the market is the increased popularity of coffee shops, fast-food restaurants, and the “take-away” beverage culture. The lifestyles of city dwellers, commuting, and consuming on the go have raised the need for convenient beverage carry-along containers, thereby making paper cups a common service type.

Also, concerns regarding hygiene and safety further impact the market demand. Paper cups are safer because they prevent cross-contact contamination. This feature has increased the demand for paper cups, especially after the pandemic. People have become more health-conscious, and they avoid contacting any equipment or object that may result in the transmission of viruses or germs.

The growth is fueled by environmental and regulatory influencers. Governments and local authorities around the globe are bans and discourages the usage of single-use plastics, thereby compelling companies to shift towards paper alternatives. Paper cups, although needing barrier layers, the inventions and developments underway around water-based and bio-based linings make paper cups more environmentally compatible and regulation-friendly by the day. The sustainability pledge by multinational foodservice companies hastens the adoption of responsibly produced paper cups.

The rise in the organized retail industry, vending infrastructure, and delivery infrastructure is also helping the market grow. Paper cups are suitable for automated filling processes and logistical processes, making them apt for scalable businesses. At the same time, developments in the area of paperboard durability, insulation, and printing technology are helping manufacturers develop differentiated products. It is, therefore, helping the paper cup market grow steadily globally.

Case Study on Cost Model of Paper Cups Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale paper cups manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed paper cups manufacturing plant in India. This plant is designed to manufacture 25 million units of paper cups annually.

Manufacturing Process: A series of paper conversion, formation, and post-production processes are employed to manufacture paper cups, which can provide a leak-tight, clean, and rigid container suitable for carrying beverages. The manufacturing process includes selecting a quality paperboard, usually made from virgin materials with proper attention to paper management, to meet strength and food safety standards when producing cups. A thin layer of materials, such as water-based coating, bio-based linings, or polymer films, must be coated or laminated over paperboard to resist penetration to maintain a non-permeable paper cup. The paperboard needs to be printed with packaging designs or nutritional data through flexographic and offset printing devices. Following the printing process, the sheets or rolls of paperboard are cut into cup blanks and discs for the bottom of the cup. The side wall blanks are then placed in cup-forming machines that convert them into cylinders, sealed on their side seam through heat-sealing, ultrasonic sealing, and other adhesive bonding processes. The bottom disc is then placed inside the cylinders and sealed to make a leak-free bottom. The rim on top of the cup is curled for rigidity and creating a smooth surface for drinking. In insulated or double-walled cups, an extra paper sleeve or wrapping is applied around the cup. Finished cups are inspected for quality to check the strength of the seam, leak-proofing, size accuracy, and print quality. Cups that are found to meet quality standards are packaged and ready for shipment. All these processes include cleanliness, automation, and minimizing waste, as advised by cup manufacturers to ensure quality and high production rate.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

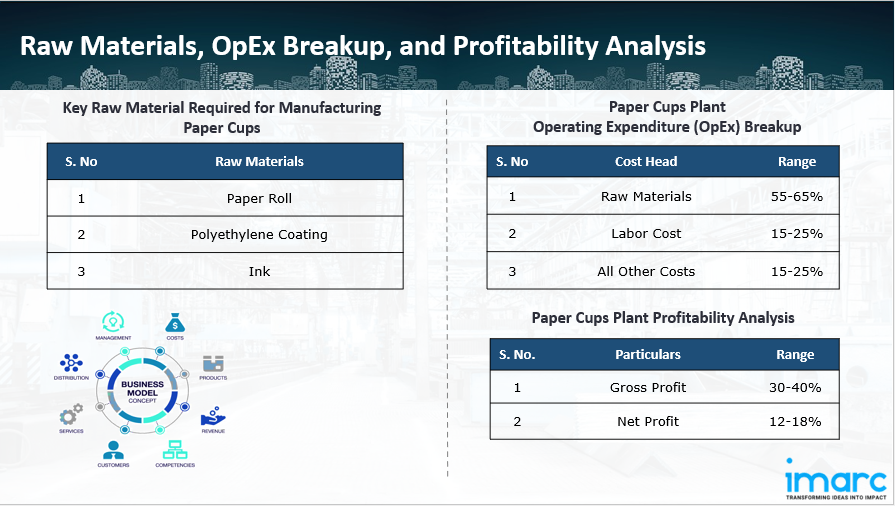

The basic raw materials required for paper cups manufacturing include:

- Paper Roll

- Polyethylene Coating

- Ink

Machine Section or Lines Required:

- Printing

- Cutting

- Forming

- Bottom Sealing

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in paper cups manufacturing plant ranges between 55-65%, labor cost ranges between 15% to 25%, and all other costs ranges between 15-25% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 30-40%, and net profit lie between the range of 12-18% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the paper cups manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 25 million units of paper cups annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In July 2025, WinCup, Inc., a prominent national manufacturer of disposable foodservice products, announced that it has acquired ConverPack Inc., a global producer of hot and cold paper cups in a strategic move that will strengthen the company's capacity to produce more environmentally friendly foodservice products.

- In July 2025, Starbucks has started introducing paperboard to-go cups for hot beverages in ten European nations, substituting a mineral-based substitute consisting of silicon dioxide for the conventional polyethylene (PE) barrier coatings.

- In March 2025, Huhtamaki, a world leader in environmentally friendly food packaging, announced the creation of ProDairy, a line of recyclable single-coated paper cups made especially for yoghurt and dairy products.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104