Seamless Tube Cost Model: From Solid Billets to High-Performance Applications

_11zon.webp)

What is Seamless Tube?

Seamless tubes consist of high-strength, hollow cylindrical products that are produced without welds with uniform structure and higher mechanical performance. Made from solid steel billets using extrusion and piercing operations, seamless tubes boast high dimensional precision, good resistance to pressure, and the capacity to handle high temperature and corrosive environments.

Key Applications Across Industries:

Seamless tubes can be made in carbon steel, alloy steel, and stainless-steel grades based on the application. Some of its key characteristics are high tensile strength, fatigue strength, homogenously grained structure, and improved safety performance because of weld joint absence. Seamless tubes find extensive applications across various industries like oil and gas, power generation, automobile, construction, and mechanical engineering. Its uses are in hydrocarbon pipelines, boiler tubes, hydraulic cylinders, and structural parts. The key benefits are in terms of durability, reliability in harsh operating conditions, and versatility in major industries. From an economic perspective, seamless tubes minimize downtime and safety, which converts to overall cost-effectiveness in the long run. As demand for high-strength tubular products in the energy, automotive, and infrastructure sectors expands, seamless tubes have a bright future as an important industrial material.

What the Expert Says: Market Overview & Growth Drivers

The global seamless tube market size reached USD 222.91 Billion in 2024. According to IMARC Group, the market is projected to reach USD 376.95 Billion by 2033, at a projected CAGR of 6.2% during 2025-2033. Several perennial drivers propel the market for seamless tubes. The energy and energy-related sectors continue to be the biggest consumers, with exploration, drilling, and pipelines demanding high-performance tubes.

The power sector, especially in thermal and nuclear power plants, creates demand for boiler and heat exchanger tubes. Automobile manufacturers use seamless tubes in safety-critical parts like steering columns and fuel injection systems. The building sector adds on with demands in heavy structural engineering. Future trends in the next five years are the use of advanced alloy tubes for hydrogen transport, the growth of seamless tubes for carbon capture and storage facilities and automating manufacturing to achieve greater precision and cost savings. Competitive strengths are their high-pressure reliability and seamless construction that reduces weak points. Challenges still exist due to volatility in raw material prices, high energy usage, and high capital utilization processes. On sustainability, tubes are recyclable, and producers are rapidly turning towards energy-efficient methods. Industry actions are capacity additions, process control through digital monitoring systems, and implementation of green steel policies for decreasing carbon footprints.

Case Study on Cost Model of Seamless Tube Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a large-scale seamless tube manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed seamless tube manufacturing plant in United States. This plant is designed to produce 300,000 tons of seamless tube annually.

Manufacturing Process: The production of seamless tubes starts with the preparation of scrap steel, which is charged into an Electric Arc Furnace (EAF) and melted by high heat into molten steel. The molten steel is then purified by oxygen injection and alloying to get rid of impurities such as sulfur and phosphorus, and then continuously cast into billets. These billets are cooled, cut, and tested for flaws before they are heated in a Rotary Hearth Furnace to enhance malleability. When heated, billets are pierced where barrel-shaped rollers press down on it to create a hollow shell. The hollow shell is then rolled in a plug mill where conical rolls and a mandrel regulate wall thickness and diameter to ensure roundness and dimensional correctness. The tubes are then subjected to dimensional control by continuous rolling, followed by stress relief and structural integrity by cooling. Subsequently, the tubes are inspected for surface quality, dimensions, and defects after cooling. They are finally cut to specified lengths by precision cutting and securely packaged to avoid damage during transportation. This continuous tube manufacturing process provides high strength, consistency, and quality, rendering them appropriate for stressful applications across industries including oil and gas, automotive, and construction.

_11zon.webp)

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials used in the seamless tube producing plant are scrap steel, iron ore, coal, limestone, oxygen, chromium, nickel, and other materials. For a plant producing 1 ton of seamless tube, 0.83 ton of scrap steel, 0.69 ton of iron ore, 0.18 ton of coal, 0.10 ton of limestone, 0.06 ton of oxygen, 0.15 ton of chromium, 0.10 ton of nickel, and 0.05 ton of other materials are required.

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

.webp)

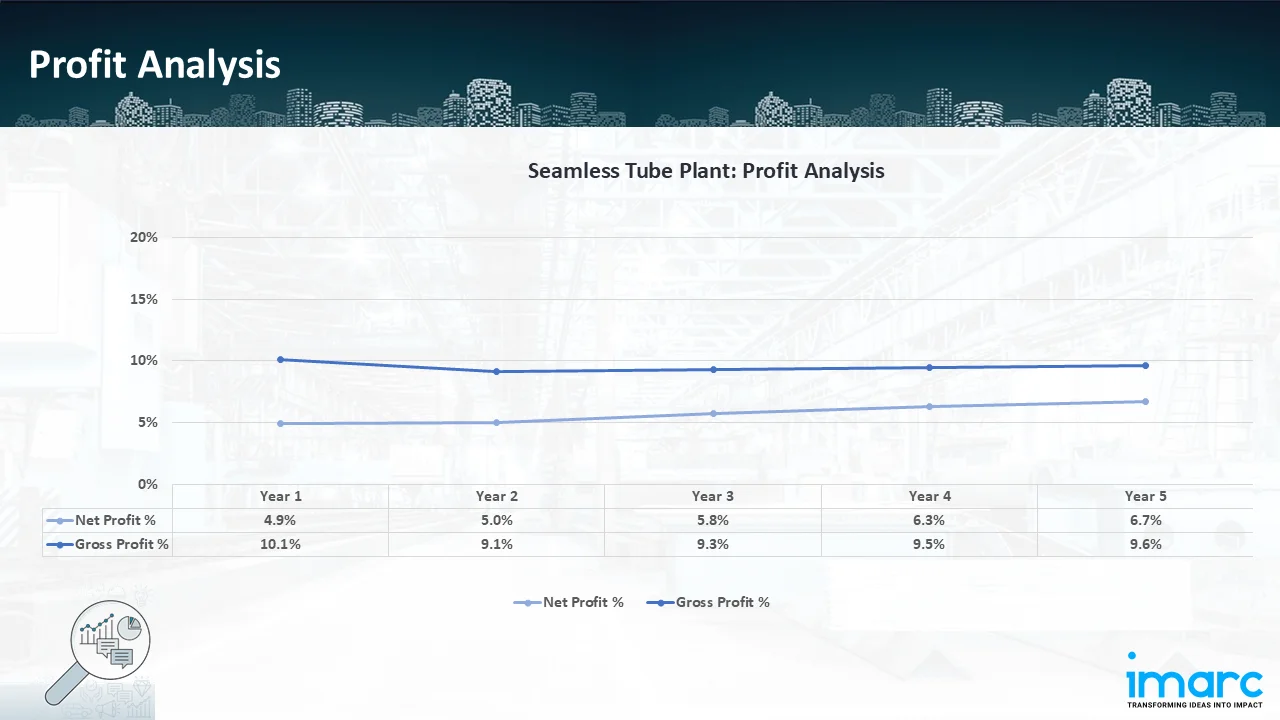

- Profitability Analysis Year on Year Basis: The proposed seamless tube plant, with a capacity of 300,000 tons of seamless tube annually, achieved an impressive revenue of US$ 1.24 billion in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins fall from 10.1% to 9.6% by year 5, and net profit rises from 4.9% to 6.7%, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the seamless tube manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of producing 300,000 tons of seamless tube annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In March 2025, Maharashtra Seamless Limited (MSL) announced obtaining a sizable contract valued at over 298 crores for the delivery of seamless pipes in the oil and gas industry. The company made the announcement in a regulatory filing.

- In November 2024, Walsin Lihwa Corporation announced that it has successfully acquired Mannesmann Stainless Tubes GmbH through Cogne Acciai Speciali S.p.A., a 70% owned subsidiary, for a total equity value of about €116 million. The purchase of MST, a well-known producer of seamless tubes for critical environments with operations in Germany, France, Italy, and the US, greatly broadens and deepens Walsin's clientele and fuels its goal of reaching more customers in high-end market niches.

- In April 2024, a new threading facility for hot rolled seamless steel tubes is being built in the Port of Caddo-Bossier as part of the expansion of BENTELER Steel/Tube Manufacturing Corporation, a prominent worldwide metal processing specialist. The business will be able to simplify supply chains for clients in the engineering, energy, and oil and gas industries thanks to the US$ 21 million investment.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104