Aluminum Utensils Cost Model: Focused on Cost and Pricing

What is Aluminum Utensils?

Aluminum cookware and kitchenware are popular cookware and kitchenware items produced mainly with high-purity aluminum, which are light in weight, have high heat conductivity, and are resistant to corrosion. Aluminum utensils involve a wide array of products ranging from pots, pans, pressure cookers, frying pans, serving trays, ladles, and baking dishes.

Key Applications Across Industries:

Aluminum's superior heat distribution has the ability to distribute heat evenly, thus saving energy, and hence is a popular choice for both household and commercial kitchens. In addition, aluminum cookware is inexpensive relative to stainless steel and copper options, yet with simple maintenance and longevity. Utensils may be forged, die-cast, or sheet-formed depending on the production technique and frequently undergo surface treatments like anodizing, non-stick coating, or polishing for maximum performance and durability. Anodized aluminum, specifically, provides added scratch resistance and visual appeal, increasing the use life of cookware. Given the increasing consumer interest in convenience, health, and sustainability, contemporary aluminum utensils are being made more induction-capable, toxin-free, and recyclable. Global manufacturers are reinventing themselves with cutting-edge non-stick coatings and ergonomic design to suit changing trends in the kitchen. Aluminum utensils thus form a vital and changing category in the global cookware industry, weighing functionality, price affordability, and environmental friendliness.

What the Expert Says: Market Overview & Growth Drivers

The global aluminum utensils market reached a value of USD 7.22 Billion in 2024. According to IMARC Group, the market is projected to reach USD 13.27 Billion by 2033, at a projected CAGR of 6.6% during 2025-2033. The global aluminum utensils market is propelled by a blend of urbanization, shifting lifestyles, and sustainability trends.

One of the main drivers is the rising demand for light, energy-saving, and inexpensive cookware. Aluminum's high heat conductivity and low price make it best suited for middle-income families, especially in the emerging economies of India, China, and Southeast Asia, where domestic cooking is still common. Additionally, the expansion of the hospitality and food service sectors globally has amplified demand for durable, high-performance cookware, further fueling aluminum utensil sales. The rising popularity of non-stick and anodized aluminum cookware offering easy cleaning and enhanced food safety has also broadened its appeal among health-conscious consumers. From a sustainability point of view, aluminum's 100% recyclability meshes well with world environmental objectives and the increasing trend towards green kitchen products. Technical developments like hard anodizing, ceramic coating, and induction-base integration are making it possible for makers to aim high-end segments without compromising on aluminum's cost position advantage. Development of e-commerce and organized retailing has also enhanced product accessibility, allowing smaller players to access global consumers. In addition, government policies encouraging domestic production and export of cookware, especially in Asian countries, are bolstering industry prospects. Rising disposable incomes, fast-paced modernization of kitchens, and the world's shift towards environmentally friendly materials are about to make aluminum utensils continue steady demand across the globe, filling the gap between functionality, affordability, and environmental sustainability.

Case Study on Cost Model of Aluminum Utensils Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale aluminum utensils manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed aluminum utensils manufacturing plant in India. This plant is designed to produce 500 tons of aluminum utensils annually.

Manufacturing Process: The aluminum utensil manufacturing process entails a number of well-controlled steps to make the product durable, light in weight, and heat-conductive enough for home and business use in the kitchen. Most processes start with high-purity aluminum ingots or sheets, which are initially heated and annealed to enhance malleability and minimize cracking when forming. For sheet-formed items like trays, plates, and lids, aluminum sheets are blanked and shaped via stamping or pressing operations, where high-pressure mechanical presses form the metal into the utensil shape. For cast or forged cookware, like heavy-duty pots, pans, or pressure vessels, aluminum is forged under pressure to create a compact, uniform structure or die-cast into shape to develop intricate forms with wall thickness uniformity. The initial forming is followed by trimming, deburring, and edge-finishing to remove surplus material and form smooth, safe edges. Based on the product requirements, the surfaces can then be anodized, polished, or coated with non-stick films to enhance corrosion resistance, scratch resistance, and visual appearance. For non-stick cookware, other steps involve surface roughening, application of primer, and curing of non-stick coatings for adhesion and durability. Lastly, every utensil undergoes quality control checks such as dimensional accuracy, surface integrity, and heat distribution tests prior to packaging. New-age manufacturing units can further incorporate automated inspection technologies to maintain uniformity in mass production. Such a precise synergy of forming, surface treatment, and quality inspection enables aluminum utensils to provide effective heat conduction, durability, and ease of use, making them an essential part of kitchens globally.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

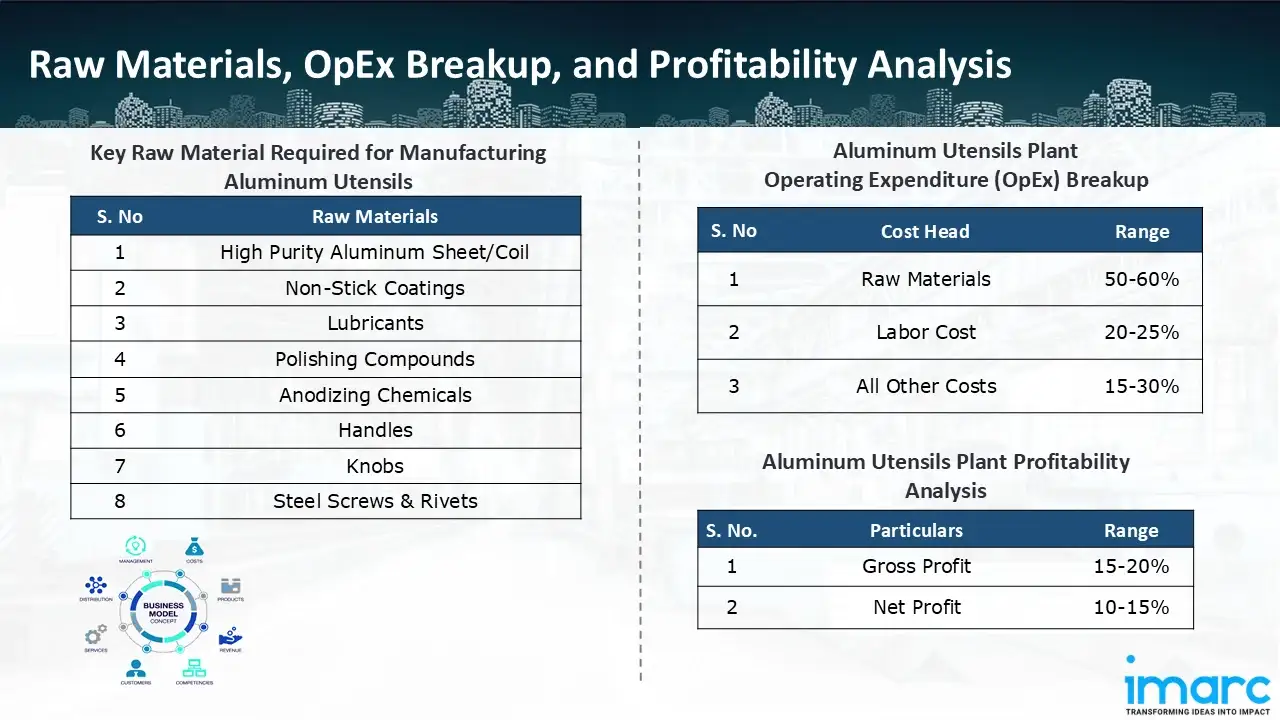

The basic raw materials required for aluminum utensils manufacturing include:

- High Purity Aluminum Sheet/Coil

- Non-stick Coatings

- Lubricants

- Polishing Compounds

- Anodizing Chemicals

- Handles

- Knobs

- Steel Screws and Rivets

Machineries Required:

- Melting Furnace (Oil/Gas/Electric Induction)

- Casting Machine

- Rolling Mill

- Coil/Sheet Slitter & Shearing Machine

- Hydraulic Shearing Machine, Power Press / Blanking Press

- Circle Cutting Machine

- Hydraulic / Mechanical Deep Drawing Press

- Spinning Lathe, Hydraulic Press with Dies/Moulds

- Trimming Press / Circular

- Trimming Machine

- Beading Machine / Edge Rolling Machine

- Polishing / Buffing Machines

- Abrasive Belt Grinding Machine

- Shot Blasting (For Matte/Textured Finish)

- Anodizing Tank

- Rectifier

- Chemical Handling System

- Spray Coating Booth

- Curing Oven

- Riveting Machine / Press

- Drilling Machine

- Spot Welding Machine

- Assembly Tools

- Leak Testing Machine

- Quality Check Instruments (Calipers, Gauges and Hardness Testers)

- Packaging Machinery (Strapping, Carton Sealing and Shrink Wrapping)

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in an aluminum utensils manufacturing plant ranges between 50-60%, labor cost ranges between 20% to 25%, and all other costs ranges between 15-30% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 15-20%, and net profit lie between the range of 10-15% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the aluminum utensils manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 500 tons of aluminum utensils annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In July 2024, the Bureau of Indian Standards has developed regulations pertaining to these critical kitchen goods, following the Commerce and Industry Ministry's March 14 decision mandating the ISI mark for stainless steel and aluminum utensils.

- In June 2024, the U.S. debuts KitchenAid® Ceramic Forged Aluminum Cookware in two trendy colours, Empire Red and Onyx Black, in collaboration with KitchenAid®, one of the most well-known gourmet kitchen product brands in the world. Only a few Walmart locations and Walmart.com are currently carrying the new collection.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104