Avocado Oil Supply Chain: A Comprehensive Cost Model

_11zon.webp)

What is Avocado Oil?

Avocado oil is a nutritious oil pressed from the pulp of avocados (Persea americana), in contrast with most oils, which are seed derived. Avocado oil is valued for its rich content of monounsaturated fats, especially oleic acid, in addition to necessary vitamins like E, A, and D.

Key Applications Across Industries:

Avocado oil has a mild, buttery taste and very high smoke point and is used both in food preparation and cosmetics. In the culinary world, it's utilized in cooking, dressings, and dietary supplements. In cosmetics and skincare, its antioxidant and moisturizing effects qualify it for creams, serums, and hair care treatments. Avocado oil comes in two main forms: cold-pressed extra virgin oil and refined oil, both with varying flavor profiles and nutritional content.

What the Expert Says: Market Overview & Growth Drivers

The global avocado oil market reached USD 610.5 Million in 2024. According to IMARC Group, the market is projected to reach USD 886.0 Million by 2033, exhibiting a CAGR of 4.2% during 2025-2033. Rising global demand for natural and healthy products is a prime driver of the avocado oil market. Increased health awareness among consumers, particularly for heart health and anti-inflammatory diets, has raised the demand for oils with high monounsaturated fats such as avocado oil. Its use in various industries such as culinary, cosmetic, and pharmaceutical is also an added driver of demand.

The demand for clean-label and plant-based foods is driving the application of avocado oil in organic foods, dressings, and dietary supplements. In the personal care industry, the trend towards natural and green skincare ingredients resulted in a boom of avocado oil-based products with its moisturizing and non-comedogenic characteristics. Further, broader retail channels, such as e-commerce websites, have increased access for buyers. Positive farming innovations and growing avocado production in Latin America, Kenya, and South Africa also are driving market supply and export expansion. Last, premium positioning and good marketing around its health attributes keep on driving demand worldwide.

Case Study on Cost Model of Avocado Oil Processing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a large-scale avocado oil processing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed avocado oil processing plant in Mukono, Uganda. This plant is designed to produce 15.8 tons of avocado oil per day.

Processing Process: Avocado oil production involves a series of careful and quality-controlled processes for the extraction of oil without compromising its nutritional value. The process starts with harvesting and washing mature avocados, then de-pitting and peeling to remove the pulp. The pulp is mechanically crushed and malaxed gently at controlled temperatures to initiate oil release. Lastly, the mash is centrifuged, separating the oil from solids and water through high-speed spinning. For extra virgin avocado oil, this is the last step prior to filtration and bottling, resulting in a cold-pressed, unrefined product. For refined avocado oil, crude oil goes through neutralization, bleaching, and deodorization to eliminate free fatty acids, pigments, and odors to be ready for high-heat cooking. Along the way, temperature and oxidation control are important to maintaining oil quality. The end oil is filtered, analyzed for quality specifications like acidity and peroxide value, and subsequently bottled or put into bulk containers for sale.

_11zon.webp)

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials used in the refined avocado oil processing plant include avocado, caustic soda and activated clay. For a plant processing 1 ton of refined avocado oil, 9.5 tons of avocado, 0.005 tons of caustic soda and 0.021 tons of activated clay is required.

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a processing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

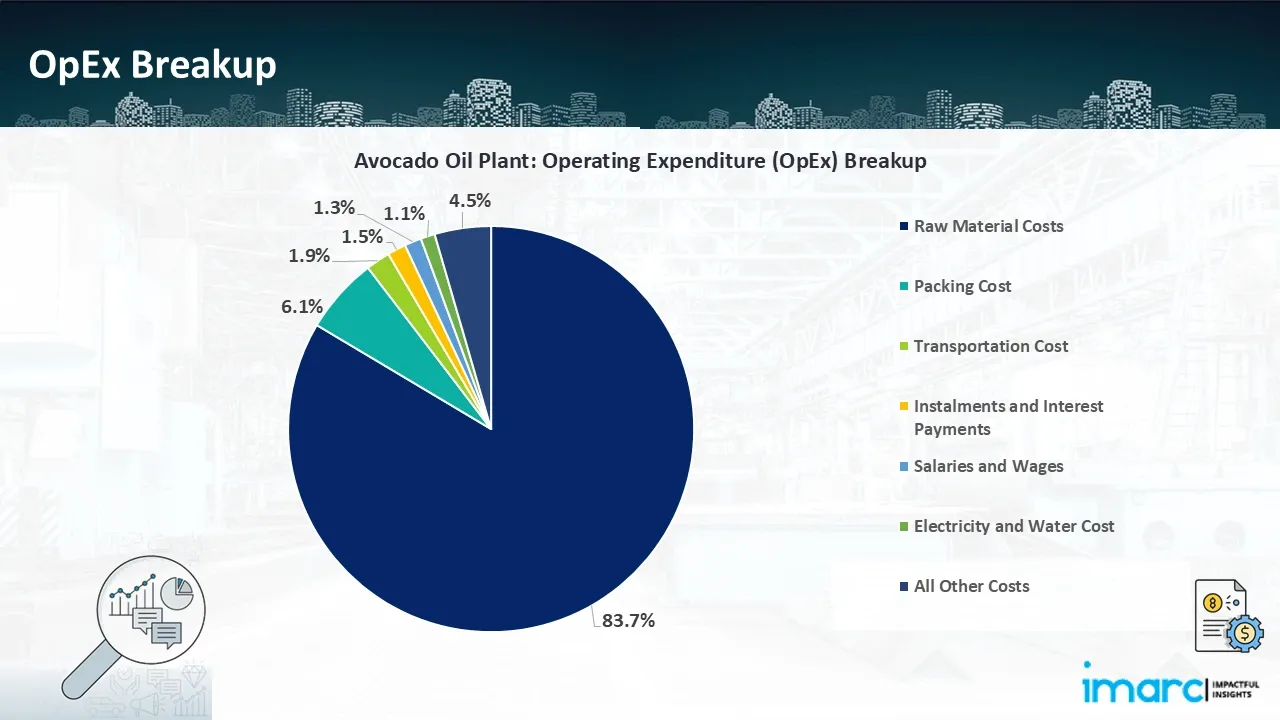

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a processing plant effectively. Opex in a processing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a processing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

- Profitability Analysis Year on Year Basis: The proposed avocado oil plant, with a capacity of approximately 15.8 tons of avocado oil per day, achieved an impressive revenue of US$ 44.3 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins improve from 40.8% to 41.2% by year 5, and net profit rises from 27.4% to 28.3%, highlighting strong financial viability and profitability.

.webp)

Conclusion & IMARC's Impact:

Our financial model for the avocado oil processing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, processing, capital expenditure, and operational expenses. By addressing the specific requirements of producing 15.8 tons of avocado oil per day, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights for strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale processing ventures.

Latest News and Developments:

- In July 2025, Sahel Capital announced a US$ 1 million debt investment in Persea Oil, a prominent manufacturer of avocado oil with operations in Kenya and Tanzania, through its Social Enterprise Fund for Agriculture in Africa (SEFAA).

- In March 2025, Fresh Del Monte Produce purchased the majority of Avolio, a producer of avocado oil in Uganda. As part of its expansion strategy for speciality ingredients, Del Monte is able to scale Avolio's extraction technology to process up to 140 metric tonnes of avocados per day and increase output worldwide thanks to this calculated decision.

- In January 2025, Avo Africa of Tanzania put into service a large-capacity avocado oil processing facility in Makambako (Njombe Region). By mid-2025, it will have doubled to 1,200 tonnes per day from its initial 600 tonnes.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the processing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish processing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104