Cost Structure Analysis of Buns: A Cost Model Approach

_11zon.webp)

What is Buns?

A bun is a small, round or oval-shaped, soft-textured bread product that can be slightly sweet or savory in taste. Made chiefly of wheat flour, yeast, sugar, salt, water, and fat, buns are found in most cuisines around the globe.

Key Applications Across Industries:

They are usually used as fillers or toppings carriers, e.g., burger buns, sandwich buns, or sweet buns with dried fruit or cream. Buns can be steamed or baked and can have toppings such as glazes or sesame seeds. Versatile to use, buns appear in both traditional bakeries and commercial fast-food outlets for both daily and festive use. They vary from plain bread rolls through to more complex types such as brioche or bao buns, supporting a broad range of consumer preferences and cultural uses.

What the Expert Says: Market Overview & Growth Drivers

The global bun market reached USD 29.6 Billion in 2024. According to IMARC Group, the market is projected to reach USD 54.0 Billion by 2033, exhibiting a CAGR of 6.9% during 2025-2033. The market for buns is mainly fueled by growing urbanization and escalating demand for ready-to-eat, convenient food items in India and around the world.

Quick-service restaurants (QSR), cafes, and food ordering apps have substantially increased demand for burger buns and sandwich buns. Evolving lifestyles, with higher consumers demanding easy-to-eat meals and snacks, further drive consumption of packaged buns. On top of this, the increased penetration of Western diets in developing economies has spurred bakery items, such as buns, in daily meals. Increased disposable incomes have also contributed to expenditure on bakery items, particularly in urban and semi-urban markets. Product innovations such as multigrain, gluten-free, high-protein, and artisan-style buns are spurring health-oriented and premium-segment consumers. Furthermore, the increase in organized retail and cold chain logistics is promoting greater availability and shelf life of buns. Cumulatively, these drivers are behind the long-term expansion of the bun market through both foodservice and retail channels.

Case Study on Cost Model of Bun Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a large-scale bun manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed bun manufacturing plant in Kazakhstan. This plant is designed to produce 2.4 tons of buns per hour.

Manufacturing Process: The production of buns starts from raw material acquisition, with major ingredients such as flour, water, yeast, and salt, which are placed in silos or tanks and weighed in measuring accuracy. Under mixing and dough feeding, there is industrial mixing to combine the ingredients to create elastic dough, which is then transported using food-grade belts. Forming involves the dough being divided and shaped into bun form prior to being taken for proofing. Proofing rooms have regulated temperature and humidity to activate the yeast and form texture. The dough proceeds to baking ovens through conveyor belts next. De-panning, after baking, utilizes vacuum belts to extract buns from the pans. The cooling area provides buns with the optimal temperature, which is vital in order to preserve quality. Then comes a quality check and packaging stage involving metal detection, weighing, bagging, labeling, and, if necessary, deep freezing. Curved conveyors and spiral towers may be employed to rationalize movement between stages for effective and sanitary production.

_11zon.webp)

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials used in the bun manufacturing plant include refined flour, water, yeast, salt and sugar. For a plant manufacturing 1 ton of bun, 1 ton of refined flour, 0.59 tons of water, 0.02 tons of yeast, 0.02 tons of salt and 0.003 tons of sugar is required.

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a Manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

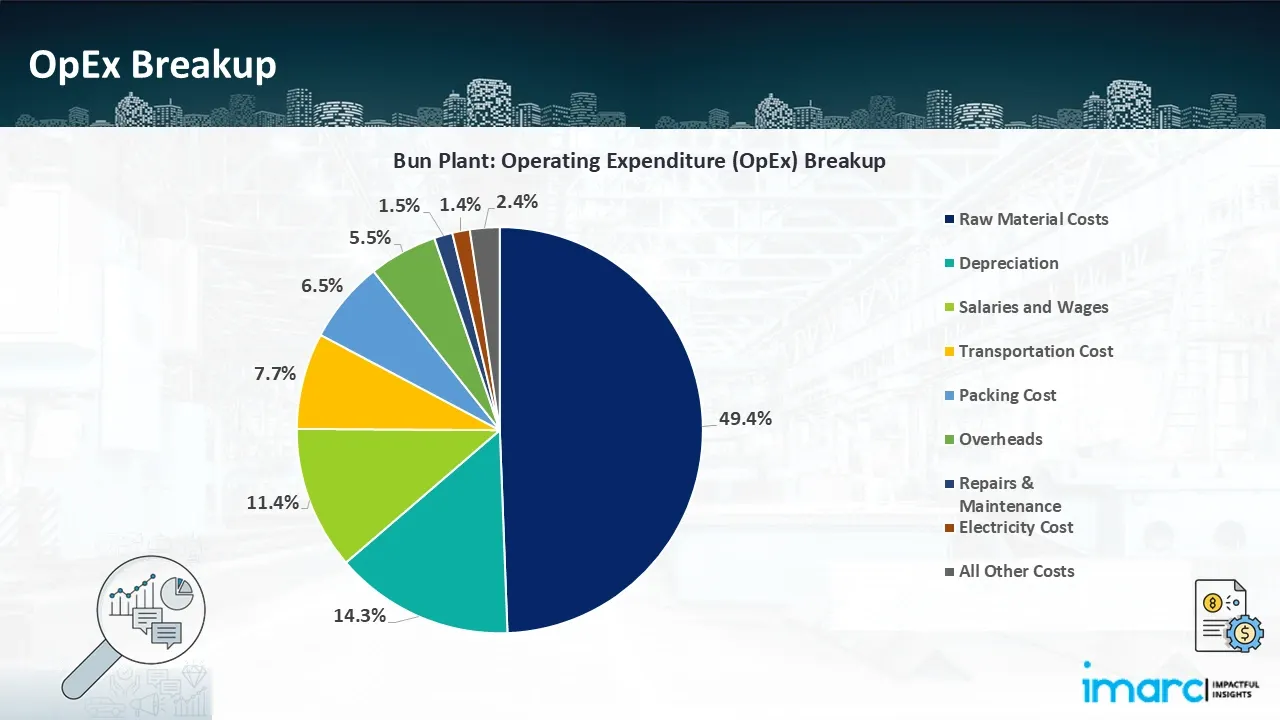

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a Manufacturing plant effectively. Opex in a Manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a Manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

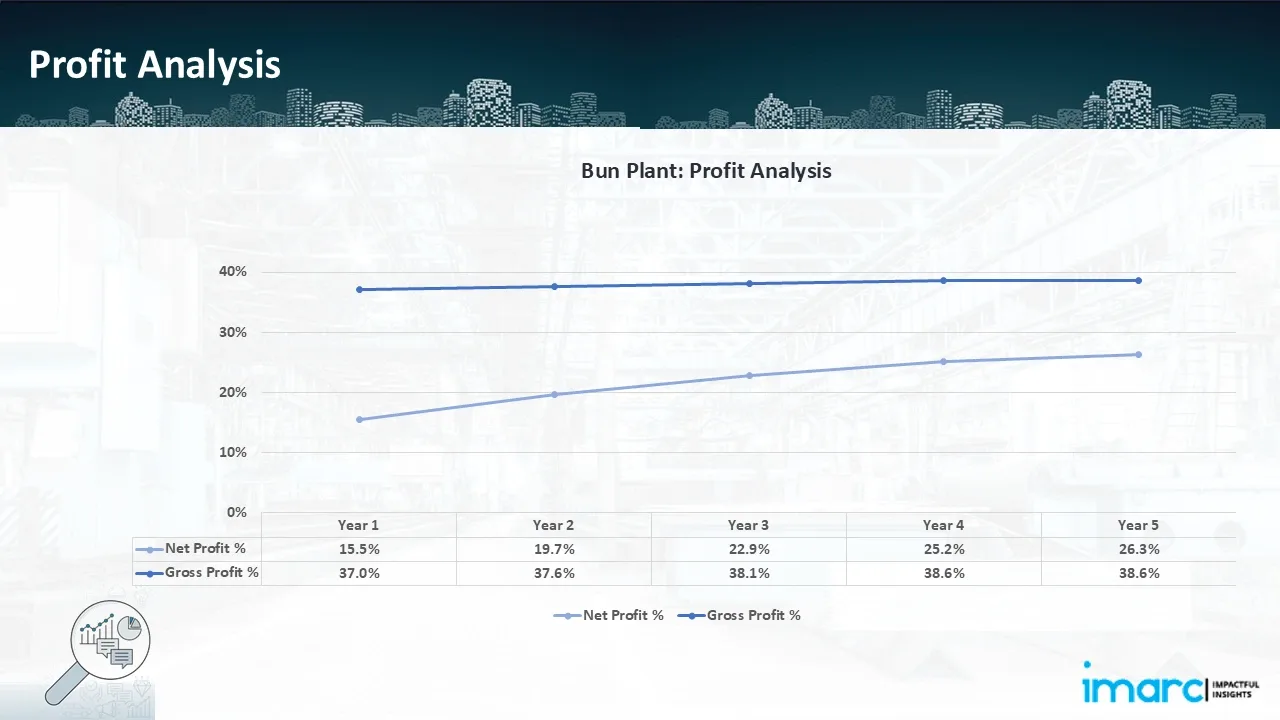

- Profitability Analysis Year on Year Basis: The proposed bun plant, with a capacity of approximately 2.4 tons of buns per hour, achieved an impressive revenue of US$ 7.34 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins improve from 37.0% to 38.6% by year 5, and net profit rises from 15.5% to 26.3%, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the bun manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, Manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of producing 2.4 tons of buns per hour, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights for strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale Manufacturing ventures.

Latest News and Developments:

- In April 2025, Crown Bakeries (USA) declared that it will be constructing a high-speed bun production line at its Pleasant Prairie, Wisconsin facility. This line would have the capacity to produce up to 2.3 million buns daily. By November 2025, the line from AMF Bakery Systems should be fully operating to meet the growing demand from wholesale customers across the country.

- In April 2024, ACE Bakery debuted a high-end range of artisan burger buns, which included slider, brioche, classic, potato, and black and white sesame variations. Foodservice and retail businesses benefit from the long shelf life and craftsmanship of delayed fermentation that these buns offer.

- In February 2024, Banquet d'Or® (under Vandemoortele) introduced two gourmet burger buns with clean-label ingredients and striking themed designs: the Ultimate Brioche Hamburger Bun and the Chilli Burger Bun.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the Manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish Manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104