The Business Case for Electric Buses: A Strategic Cost Model

_11zon.webp)

What is Electric Bus?

The electric bus industry is the part of the transportation sector that deals with the production and installation of buses that run completely or partially on electricity, employing battery packs or fuel cells in place of conventional diesel or gasoline engines.

Key Applications Across Industries:

The buses deliver lower greenhouse gas emissions, lesser noise levels, and enhanced energy efficiency, and thus they are a prime solution for environmentally friendly public transport. They are progressively used in city transit fleets, intercity transportation, and school buses, aided by improvements in battery technology, charging infrastructure, and government policies. Electric buses can be offered in different forms, including battery electric buses (BEBs), plug-in hybrids, and fuel cell electric buses (FCEBs), depending on route length and operating requirements.

What the Expert Says: Market Overview & Growth Drivers

The global electric bus market reached USD 46.9 Billion in 2024. According to IMARC Group, the market is projected to reach USD 183.7 Billion by 2033, at a projected CAGR of 16.6% during 2025-2033.The global electric bus industry is propelled by increasing environmental pressures and the imperative to curb city air pollution, leading cities around the globe to embrace zero-emission public transport systems. Policies, subsidies, and incentives, including purchase grants, tax credits, and low-interest loans, are driving adoption considerably. Quickly advancing lithium-ion battery technology has boosted range, charging time, and cost-effectiveness, and electric buses are becoming increasingly competitive with diesel counterparts.

Besides, increasing investments in charging infrastructure, such as fast-charging and depot-based, are facilitating large-scale fleet deployment. Urbanization and rising public transit needs are compelling municipalities to update fleets with cleaner alternatives. Top manufacturers are boosting manufacturing capacities and launching innovative models with enhanced energy efficiency and better passenger comfort. In addition, corporate and educational transport segments are increasingly adopting electric buses to address sustainability targets and meet more stringent emission standards, further driving growth for the global market.

Case Study on Cost Model of Electric Bus Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a large-scale electric bus manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed electric bus manufacturing plant in Illinois, United States. This plant is designed to produce 3 electric buses per day.

Manufacturing Process: Production of electric buses begins with procuring major components like chassis, bodywork panels, battery packs, electric motors, power electronics, and interior fitments from specialized vendors on quality, reliability, and adherence to safety standards. The chassis from high-strength steel or aluminum is welded using MIG/TIG processes and then tested for stress and non-destructive testing. Then, lightweight aluminum, fiberglass, or composite panels are fitted at the paneling/cladding stage, together with comfort insulation, and a structural inspection. Painting involves surface preparation, priming, sophisticated electrostatic or robotic coating, baking, and polishing. In the assembly stage, major systems such as the electric powertrain, battery packs, suspension, brakes, wheels, interior seat, HVAC, and infotainment are fitted, high-voltage wiring and power systems inspected for safety. Strict testing then ensues, encompassing performance, braking, endurance, economy, HVAC operation, and crashworthiness, in addition to road trials. Once all tests have been passed, the bus is detailed, photographed, and dispatched to operators or customers.

.webp)

_11zon.webp)

_11zon.webp)

Mass Balance and Raw Material Required: The primary raw materials used in the electric bus manufacturing plant include powertrain system, chassis assembly, roof panel, side panels, front panel, rear panel, composite floor panel, passenger seats, driver seat and cabin, multiple interior panels and ceiling liners, dashboard and control console, interior lighting system, flooring material, door control switches, electric horn, hand holdings, passenger doors, electric bus door opener, exterior lighting system, electrical system, air conditioner, safety and auxiliary systems, side view mirrors, front bumper mounting, rear bumper mounting, side window mounting, side windows, front windshield, rear windshield and driver window. For a plant producing 1 bus of electric bus, 1 piece of powertrain system, 1 piece of chassis assembly, 1 piece of roof panel, 2 pieces of side panels, 1 piece of front panel, 1 piece of rear panel, 1 piece of composite floor panel, 40 pieces of passenger seats, 1 piece of driver seat and cabin, 6 pieces of multiple interior panels and ceiling liners, 1 piece of dashboard and control console, 6 pieces of interior lighting system, 2 pieces of flooring material, 2 pieces of door control switches, 1 piece of electric horn, 8 pieces of hand holdings, 2 pieces of passenger doors, 2 pieces of electric bus door opener, 4 pieces of exterior lighting system, 2 pieces of electrical system, 1 piece of air conditioner, 1 piece of safety and auxiliary systems, 2 pieces of side view mirrors, 1 piece of front bumper mounting, 1 piece of rear bumper mounting, 2 pieces of side window mounting, 12 pieces of side windows, 1 piece of front windshield, 1 piece of rear windshield and 1 piece of driver window are required.

Types of Machinery:

- Robot spray booth

- Central air supply system

- Drying room

- Polishing room

- Polishing room (Air pollution system)

- Lighting stand station

- Frame lifting platform

- VOCS Waste gas treatment

- Robotic spraying system

- Bus Body Assembly Equipment

- Power Truss for Welding Line

- Technical Cart for Welding Line

- Side Skin Strength Machine

- Front Frame Welding Jigs (manual type)

- Rear Frame Welding Jigs (manual type)

- Top Frame Welding Jigs (manual type)

- Floor Frame Welding Jigs (Automatic type)

- Welding fixture for front, middle and rear sections of Floor frame (manual type)

- Welding jig for small parts of Floor frame (manual type)

- Other small welding fixtures (manual type)

- Top Skin Strength Machine

- Simple body Hanger

- Robot welding system for left and right-side frames

- Automatic welding fixture to the left and right-side frame (with turn table)

- Side skin rolling machine

- Uncoiling machine

- Top skin 1 rolling machine

- Skin lifting rack

- Skin transfer vehicle

- Roof welding fixture (automatic with turn table)

- Robot welding system for roof

- Transfer cart for sub-frame

- Roll Forming Machines

- 3D Laser Welding Systems

- Metal Stamping Machines

- Body Panel Presses

- Drilling and Riveting Machines

- Side Skin Hydraulic Stretching Machine

- Charging System Testing Equipment

- Seat installation robots

- Floor covering application equipment

- Interior panel assembly stations

- HVAC system installation equipment

- Window installation systems

- Door assembly and hanging equipment

- Battery cell assembly machines

- Module assembly stations

- Pack assembly equipment

- Battery testing systems

- Automated battery management system installation

- High-voltage safety testing equipment

- Body frame combined tire

- Craft trolley

- Craft trolley guideway

- Cold tensioning machine

- Dydraulic scissors arm lifter

- Column type lifting platform

- Welding line power grid

- Welding offline body spreader

- Assembly on-line body spreader

- Air conditioning installation platform

- Glass mounting lifting platform

- Glass suction crane

- Single plate chain line for final assembly

- Assembly line power grid

- Assembly Line Suspended Power Truss

- Battery Testing Equipments

- Brake Testing Equipment

- 3D Dynamic laser wheel aligner

- Headlight tester

- Automobile side slip test bench

- Dynamometers

- Bus speed test station

- Leak Testing Machines

- Automobile axle load test bench

- Single-axis ABS brake station

- Sound level meter

- Network Control System

- Safety testing equipment

- Cable Testing Machines

- Robotic Soldering Machines

- Wire harness assembly stations

- Automated wire routing systems

- Electrical component installation fixtures

- High-voltage connection tools

- Diagnostic testing equipment

- Control system programming stations

- Robotic Arms

- Torque Tools

- Final line conveyor systems

- Wheel and tire mounting stations

- Vehicle lifting systems

- Fluid filling stations

- Light adjustment equipment

- Door fitting stations

- Overhead cranes

- Forklifts

- Automated storage and retrieval systems

- Parts delivery conveyors

- Material flow management systems

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

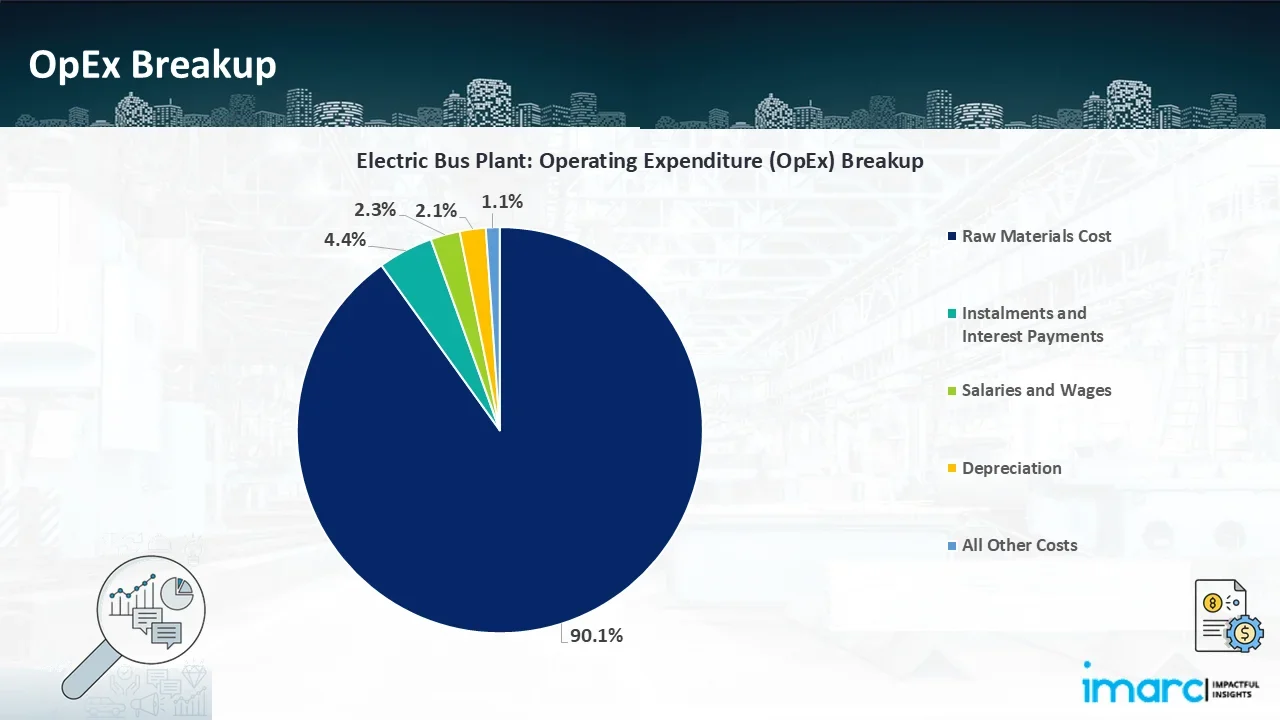

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

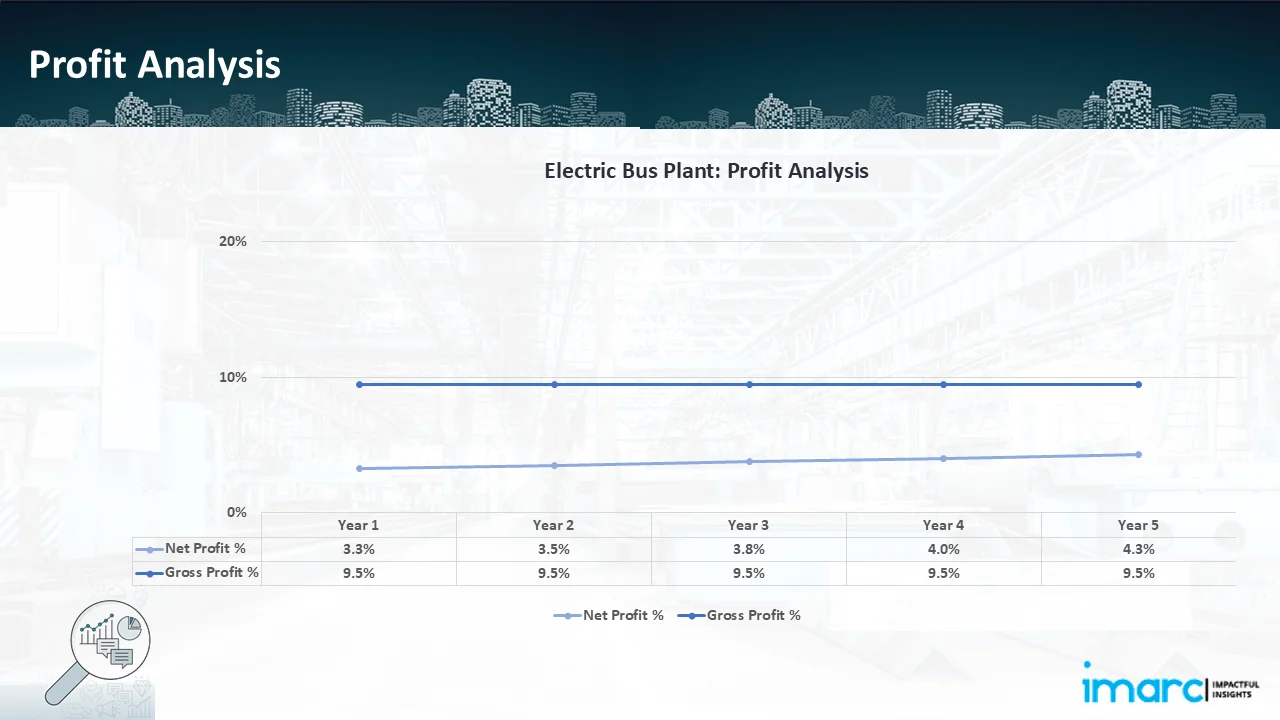

- Profitability Analysis Year on Year Basis: The proposed electric bus plant, with a capacity of 3 electric buses per day, achieved an impressive revenue of US$ 580.5 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins stayed constant at 9.5% throughout the five years, and net profit rose from 3.3% to 4.3%, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the electric bus manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of producing 3 electric buses per day, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In July 2025, 600 battery-electric buses will be ordered in a high-impact tender worth €652 million by Italy's procurement behemoth Consip to cover interurban and urban routes.

- In July 2025, BYD announced that it will expand its production footprint in Europe with a new facility in northern Hungary. By building a new plant in Komárom, the company intends to triple its local production capacity to 1,250 electric buses and trucks per year, investing 32 billion forints, or roughly US$ 94 million.

- In October 2024, Transdev in the Netherlands has placed a sizable order with Volvo Buses for 46 electric buses, which will contribute to the electrification of Utrecht's public transport system. Since the company's official partnership with bodybuilder MCV began, this is the biggest order for fully electric Volvo buses to date.

- In October 2024, Easy Green Mobility, a new subsidiary of EaseMyTrip, has announced its entry into the electric bus manufacturing industry. For R&D and the establishment of a manufacturing facility, the company is spending INR 200 crore over two to three years. This action is in line with EaseMyTrip's goal of gaining a sizeable portion of India's expanding EV market.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104