Electrical Panel Cost Model: Economics of Panel Manufacturing

What is Electrical Panel?

An electrical panel, also called a distribution board or switchboard, is an important installation in electrical infrastructure that acts as the main center for the distribution, control, and protection of electrical power within residential, commercial, and industrial systems. It acts as the point at which electrical energy is received from the utility or a source of power generation and is distributed to various circuits and equipment in an organized manner. It houses protective devices including circuit breakers, fuses, contactors, and relays, which offer protection to connected systems against overloads, short circuits, and voltage fluctuations.

Key Applications Across Industries:

Electrical panels are structurally enclosed metallic or insulated cabinets designed to ensure safety, accessibility, and durability. Electrical panels are categorized into main distribution panels (MDPs), sub-distribution panels, motor control centers (MCCs), and automation or control panels, each suited for specific applications. For example, MDPs control large facility power supplies, while MCCs manage the protection and control of electric motors of industrial plants. In modern installations, electrical panels are increasingly integrated with digital monitoring systems, smart metering, and IoT-based sensors to allow remote supervision, predictive maintenance, and energy optimization. Materials that ensure fire resistance and environmental protection include galvanized steel, aluminum, or thermoplastic enclosures, specifically in outdoor or industrial conditions. The design process emphasizes compliance with international standards such as IEC, NEC, or UL to ensure performance and safety. As electrical demand escalates from renewable energy to automation, electrical panels remain the backbone of power management, ensuring the safe, efficient, and intelligent operation of modern electrical systems.

What the Expert Says: Market Overview & Growth Drivers

The global electrical panel market reached a value of USD 6.52 Billion in 2024. According to IMARC Group, the market is projected to reach USD 10.34 Billion by 2033, at a projected CAGR of 5.3% during 2025-2033. The global electrical panel market is powered by a combination of urbanization, industrial growth, electrification trends, and technological advancements in energy management systems. Among the key drivers is the rapid expansion of infrastructure development in both developed and emerging economies. With the modernization of cities and construction of new commercial and industrial facilities, the demand for reliable power distribution systems increases, thereby directly boosting the demand for electrical panels. The global stride towards renewable energy, which is proceeding with installations of solar, wind, and hydroelectric generation, is yet another significant contributor, as electrical panels make up the essential interfaces between generation sources, inverters, and power distribution networks.

Other major growth factors include rising adoption of smart and automated systems. Modern electrical panels now feature digital controls, IoT sensors, and communication modules to enable real-time monitoring, fault detection, and load management. This transition toward smart electrical infrastructure aligns with industrial automation, smart grid deployment, and energy efficiency initiatives. In addition, the increased electrification of transportation and manufacturing-for example, electric vehicles, EV charging stations, and automated factories-drives demand for robust and scalable electrical panels that are suitable for increased loads and distributed energy systems. Regulatory and safety standards are also leading to innovations and improvements in the quality of panels, forcing manufacturers to adopt advanced designs that meet international safety norms. Further, increasing power consumption in residential and commercial sectors, coupled with aging electrical infrastructure in many regions, necessitates replacement and retrofitting of outdated panels. Finally, the integration of renewable microgrids, data centers, and modular construction practices further expands the scope of application of electrical panels worldwide. All these factors put together make electrical panels one of the crucial enablers in the global transition toward efficient, digital, and sustainable energy systems.

Case Study on Cost Model of Electrical Panel Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale electrical panel manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed electrical panel manufacturing plant in India. This plant is designed to manufacture 10,000 units of electrical panel annually.

Manufacturing Process: The electrical panel manufacturing process is a meticulously engineered sequence of precision fabrication, electrical assembly, and quality assurance to guarantee reliability and safety, per international standards. Design and engineering involve developing electrical schematics and layout drawings through CAD software. It is at this stage that engineers decide the circuit configurations, load capacity, and placement of components in accordance with specifications and safety codes like IEC, NEC, or UL. After finalizing the design, fabrication of the enclosure begins. Sheet metal, usually mild steel, stainless steel, or aluminum, is cut, bent, and welded on CNC machines to obtain the cabinet structure. Surface treatment, including powder coating or painting, provides corrosion resistance and insulation. Upon fabrication, the busbar system is manufactured by using high-conductivity copper or aluminum bars which are cut, drilled, and plated to offer minimum resistive losses and ensure that the current flows efficiently. Insulating materials applied between busbars prevent short circuits. The mechanical assembly follows, with mounting plates, hinges, and cable management systems installed. Electrical components such as circuit breakers, contactors, relays, meters, and control switches are mounted according to the design layout. Wiring and interconnections are done by skilled technicians, guaranteeing proper labelling and secure terminations. Once assembled, the panel is put through several quality and performance tests: continuity checks, insulation resistance tests, and functional simulations under load conditions. Further, it involves visual inspection, documentation, and certification before packaging for delivery. This comprehensively ensures each electrical panel operates safely, efficiently, and reliably in diverse industrial, commercial, or residential power distribution environments.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

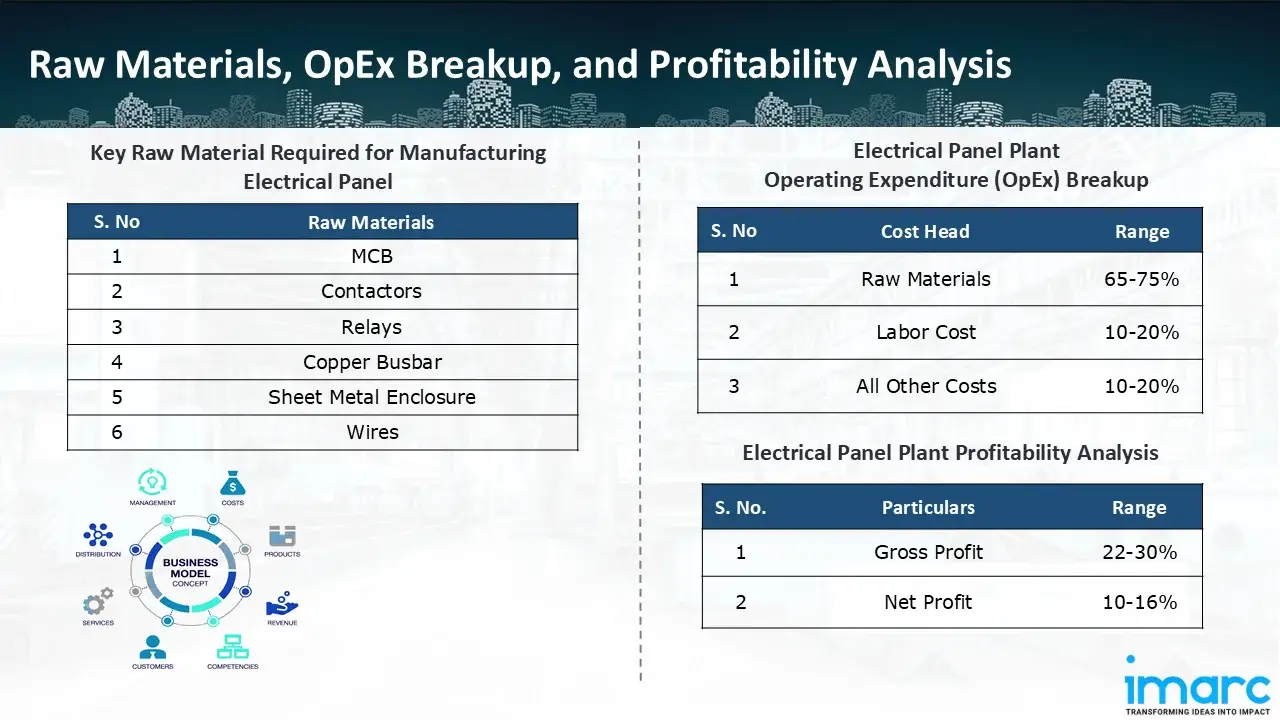

The basic raw materials required for electrical panel manufacturing include:

- MCB

- Contractors

- Relays

- Copper Busbar

- Sheet Metal Enclosure

- Wires

Machineries Required:

- Sheet Metal Fabrication

- Powder Coating

- Assembly

- Wiring

- Testing

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in electrical panel manufacturing plant ranges between 65-75%, labor cost ranges between 10% to 20%, and all other costs ranges between 10-20% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 22-30%, and net profit lie between the range of 10-16% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the electrical panel manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 10,000 units of electrical panels annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In October 2025, CG Power & Industrial Solutions, a division of the Murugappa Group, based in Chennai, intends to invest INR 748 crore to establish a new greenfield switchgear manufacturing factory in western India. Spread over 35 acres and with a built-up area of about 72,000 square meters, the proposed factory will provide a whole variety of products, such as power electronics solutions, substation automation systems, and medium-voltage (MV) and extra high-voltage (EHV) switchgear.

- In May 2025, nVent Electric plc, a world leader in electrical connection and protection solutions, announced that it has successfully completed the previously announced acquisition of Avail Infrastructure Solutions ("Electrical Products Group")'s enclosures, switchgear, and bus systems businesses for a purchase price of $975 million, funded by cash on hand, subject to customary adjustments.

- In June 2024, Siemens announced expanding its current factory in Frankfurt's Ostend neighbourhood by investing 100 million euros in a 3.5-hectare plot. The switchgear factory was reinforced with a high-speed warehouse and increased output.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104