Float Glass Manufacturing Cost Analysis: Reflections of Efficiency

What is Float Glass?

Float glass is a type of flat glass that is manufactured by floating molten glass on a bed of molten tin. This produces a smooth, uniform surface and consistent thickness. The float process was developed by Pilkington in the 1950s and revolutionized glassmaking because it enabled the production of large, flawless sheets of glass without needing polishing or grinding. The basic raw materials used-silica sand, soda ash, limestone, and dolomite-are heated in the furnace to a very high temperature, then continuously poured onto the tin bath, where the molten glass spreads out into an even layer. It cools and solidifies into a perfectly flat and perfectly transparent sheet. As it provides optical clarity and strength and is easily processed into coated, laminated, or toughened forms, float glass is used as a basic product for various applications, ranging from architectural and automotive to industrial applications.

Key Applications Across Industries:

Float glass is one of the most widely used materials in the construction, automotive, and manufacturing industries for its versatility and adaptability to various processing techniques. In architecture and construction, it is considered the most important material for windows, doors, facades, skylights, and curtain walls, given that it provides both aesthetic appeal and natural lighting. It is also the base for energy-efficient glazing systems such as low-emissivity (Low-E) and solar-control glass, which further enhance thermal insulation in buildings and reduce energy consumption. Due to its clarity and the possibility of tinting, etching, or coating, in interior design, it becomes a material for mirrors, partitions, furniture surfaces, and decorative panels.

In the automotive industry, float glass forms the base for windshields, side windows, and rear windows, which are often laminated or toughened in their preparation for improved safety and strength. Applications also occur in transport vehicles, including trains, ships, and aircraft, where clear vision and strength are imperative. Apart from these industries, float glass is important in solar energy applications, serving as the front sheet in photovoltaic panels and solar thermal collectors. Other uses of the glass include display screens, oven doors, refrigerator shelves, and electronics and appliances. Indeed, float glass has become a cornerstone of modern infrastructure, design, and sustainable technology development due to its ability to undergo coating, lamination, and chemical strengthening processes.

What the Expert Says: Market Overview & Growth Drivers

The global float glass market reached a value of USD 50.57 Billion in 2024. According to IMARC Group, the market is projected to reach USD 82.08 Billion by 2033, at a projected CAGR of 5.5% during 2025-2033. The global float glass market is driven by fast expansion of construction, automotive innovation, energy efficiency goals, and technological advancements in the processing of glass. Perhaps the most potent driver is the growth in the global construction industry, especially in emerging economies, where increasing urbanization and infrastructure investments have amplified demand for modern glazing materials. In both residential and commercial construction, float glass finds extensive application owing to its ability to let in natural light, insulation, and aesthetic versatility. This has been further pushed by the shift toward green buildings and sustainable architecture, driving demand for energy-efficient float glass variants such as Low-E, solar control, and reflective glass that contribute toward reduced energy consumption and carbon emissions. Electric and hybrid vehicle production in the automotive industry contributes to an increase in demand for lightweight and safety-enhanced glass. Float glass plays a critical role as an input to windscreen and panoramic roofs, where clarity, UV resistance, and strength are required. Other factors driving adoption come from the industry's shift toward lightweight materials in its drive for fuel efficiency. Moreover, manufacturers are now able to offer high-performance float glass due to technological advances made in glass coating, lamination, and digital printing techniques to suit specific climatic and functional requirements. This is further supported by the increasing investment in renewable energy infrastructure, especially solar photovoltaic and thermal systems, wherein float glass acts as a protective and light-transmitting layer for solar panels. Moreover, smart glass technologies with their embedded electrochromic and photochromic capabilities arise from float glass substrates. The global expansion of the market finds its basis in combinations of industrial innovation, sustainable construction practices, and the integration of new glass materials into energy and transport systems, hence positioning float glass as an essential material in the development of modern industry and architecture.

Case Study on Cost Model of Float Glass Manufacturing Plant

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale float glass manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed float glass manufacturing plant in India. This plant is designed to manufacture 600 tons of float glass annually.

Manufacturing Process: The float glass manufacturing process is a continuous and exacting industrial process wherein raw materials are converted into flawless, flat glass sheets of consistent thickness and outstanding clarity. The process starts with the batching and mixing of raw materials, mainly silica sand, soda ash, limestone, dolomite, and alumina, with small additions of iron oxide for tint and sodium sulfate as a refining agent. These materials are carefully weighed and mixed, then fed into a furnace where they are melted at about 1,500-1,600°C into a homogeneous molten glass mixture.

The molten glass flows continuously from the furnace onto a bath of molten tin in a specially designed float chamber. Since the molten glass is less dense compared to tin, it floats on the surface, spreading out uniformly and forming a smooth, flat ribbon. In the tin bath, the temperature is precisely controlled: hot enough to keep the glass molten at its entry point and cooler toward its exit, enabling the glass to solidify without distortion uniformly. As the ribbon progresses, it passes through a zone of controlled cooling, commonly known as the annealing lehr, where internal stresses are relieved to prevent cracking or warping.

After cooling, the glass ribbon is removed and cut into standard dimensions and then inspected for thickness, optical quality, and surface defects. The output can then undergo further processing, such as tempering or lamination, depending on application needs. The automation of the continuous float process ensures extremely high optical uniformity and flatness, with excellent production efficiency, and it sets the world standard for manufacturing architectural and industrial glass.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

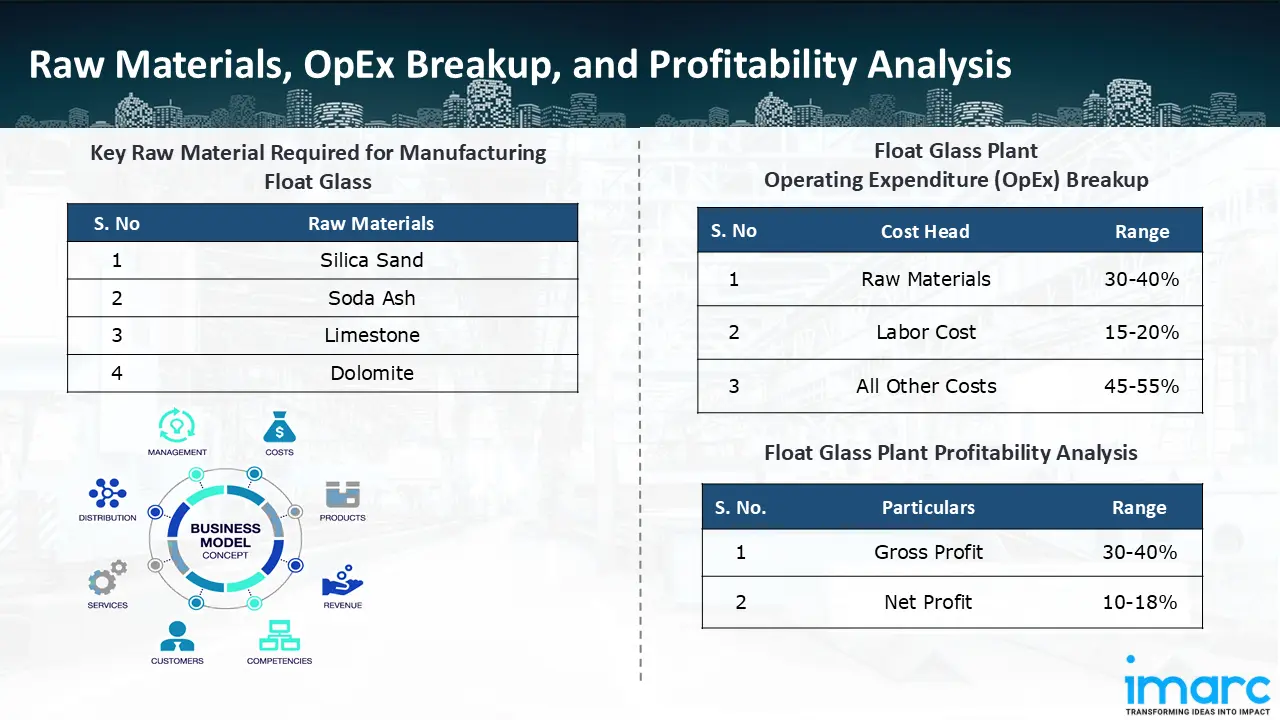

The basic raw materials required for float glass manufacturing include:

- Silica Sand

- Soda Ash

- Limestone

- Dolomite

Machine Section or Lines Required:

- Batch Mixing

- Melting Furnace

- Float Bath

- Cutting

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in float glass manufacturing plant ranges between 30-40%, labor cost ranges between 15% to 20%, and all other costs ranges between 45-55% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 30-40%, and net profit lie between the range of 10-18% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the float glass manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 600 tons of float glass annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In August 2025, Saint-Gobain announced that construction on its fifth mineral wool insulation line and seventh float glass line in Oragadam, Chennai, had begun. The Group's strategic commitment to bolstering local manufacturing capabilities and expanding in the Indian market is reinforced by this development, which represents an important milestone.

- In January 2025, Gold Plus Glass Industry, a major producer of float glass, has announced the opening of a new production plant in the Indian state of Karnataka. It announced that by joining the solar glass market with the new facility, it has increased its float glass capacity and diversified its portfolio.

- In September 2024, Toughglass India, a company based in Bengaluru, revealed that it is growing its business by establishing two new locations: one in Kerala and one in the capital of Karnataka. This results in Toughglass India's monthly production capacity surpassing 50,000 square meters.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104