Investment Assessment of a Fluoropolymers (PTFE) Manufacturing Plant: A Comprehensive Cost Model Study

What is Fluoropolymers (PTFE)?

Polytetrafluoroethylene (PTFE) refers to a tough, waxy and non-flammable synthetic resin that consists of carbon and fluorine atoms. It is manufactured through the free-radical polymerization process of chloroform, fluorspar and hydrochloric acid.

Key Applications Across Industries:

PTFE is usually used to give a non-stick coating to surfaces, especially cookware, such as pans and baking trays and industrial products. It is commonly available in granular, powder and micronized forms and exhibits various physical properties, including resistance to chemicals, heat, ultraviolet (UV) rays and fatigue, along with low water absorption and high electrical insulation.

What the Expert Says: Market Overview & Growth Drivers

According to an IMARC study, the global fluoropolymers (PTFE) market volume was at 220.9 Thousand Tons in 2024, growing at a CAGR of 3.7% from 2019 to 2024. Looking ahead, the market is expected to grow at a CAGR of approximately 4.0% from 2025 to 2033, reaching a projected volume of 318.6 Thousand Tons by 2033. One of the main factors propelling the market's expansion is the notable expansion in the chemical and industrial processing industries.

PTFE is widely used in the production of industrial goods, including rings, seals, well-drilling equipment, gaskets, vessel linings, and pump interiors. Furthermore, PTFE is utilised to increase its application across sectors by strengthening the general operation and reducing downtime of these machines and automobile components. Accordingly, because of its great resistance to severe chemicals, acids, and caustics, PTFE is also used in oil and gas exploration. Another aspect contributing to growth is the expanding medical sector globally. Physicians are increasingly using different membranes and grafts made with biocompatible PTFE for treatments in dentistry, orthopaedics, ophthalmology, and cardiovascular disease.

Case Study on Cost Model of Fluoropolymers (PTFE) Manufacturing Plant:

Objective

A client had approached us to conduct a feasibility study for establishing a mid to large-scale fluoropolymers (PTFE) manufacturing plant in Korea.

IMARC Approach: Comprehensive Financial Feasibility

We have developed a detailed financial model for the plant's setup and operations. The proposed facility is designed with an annual production capacity of 12,500 tons of Fluoropolymers (PTFE).

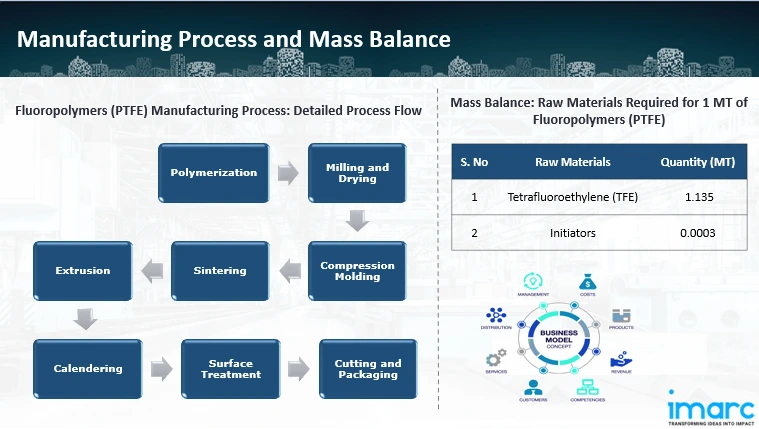

Manufacturing Process: Tetrafluoroethylene (TFE) is first polymerised in high-pressure reactors at high temperatures to produce PTFE. After the reaction is started by free radicals, PTFE polymer chains are formed, resulting in a dispersion that is subsequently cooled and hardened into resin granules. For improved processability, the resin is dried to eliminate moisture after being ground into uniform granules from large pieces. After that, PTFE granules are formed via compression moulding, which creates preforms with the required geometries by applying high pressure and temperature. By heating these preforms close to the melting point of PTFE, a process known as sintering, the granules can unite into a solid, dense structure with exceptional mechanical qualities. Melted PTFE is forced through a die during the extrusion process to produce continuous PTFE forms like rods, tubes, or sheets. Calendering compresses granules between heated rollers to create thin PTFE sheets or films. By altering the surface chemistry of PTFE, surface treatments like etching and plasma treatment improve its adhesive qualities. Lastly, PTFE materials are wrapped to ensure protection throughout transit and precisely cut to the necessary proportions. Every stage guarantees premium PTFE with desired qualities for industrial uses, such as durability, chemical resistance, and thermal stability.

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials utilized in the Fluoropolymers (PTFE) manufacturing plant include Tetrafluoroethylene (TFE) and initiators. To manufacture 1 ton of Fluoropolymers (PTFE), 1.135 tons of Tetrafluoroethylene (TFE) and 0.0003 tons of initiators is required as raw material.

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

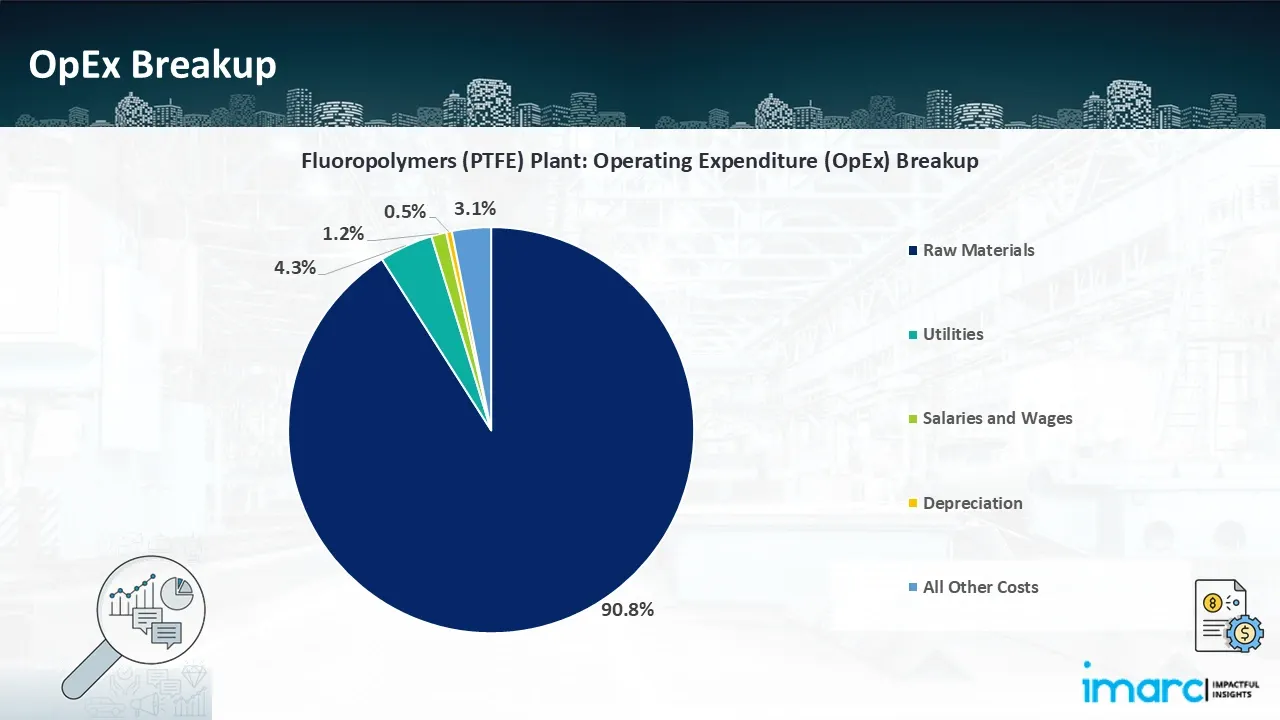

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

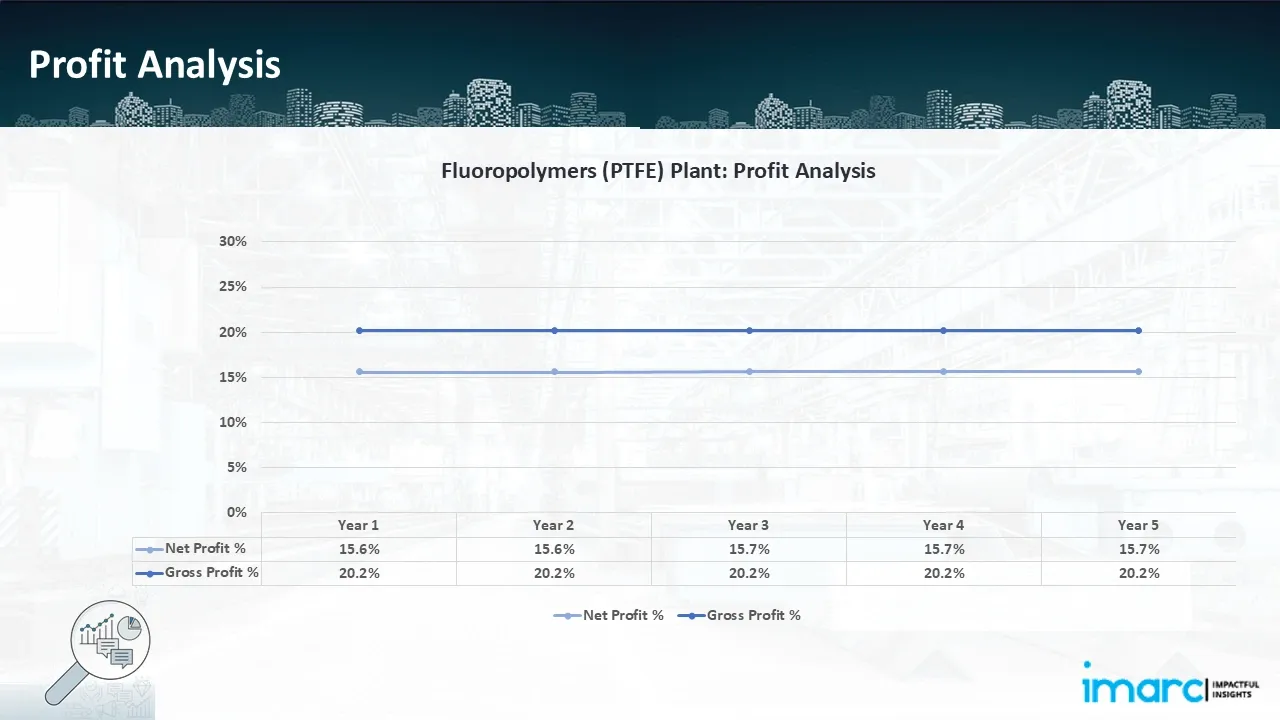

- Profitability Analysis Year on Year Basis: The proposed Fluoropolymers (PTFE) plant, with a capacity of 12,500 tons per annum, achieved an impressive revenue of US$ 79.40 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue staying constant throughout the projected period. Moreover, gross profit stood the same throughout the period at 20.2.%, and net profit slightly rise from 15.6% to 15.7%, highlighting strong financial viability and operational efficiency.

Conclusion & IMARC's Impact:

We meticulously developed our financial model for the Fluoropolymers (PTFE) producing plant to meet the client's objectives. It offered an in-depth examination of production costs, considering capital expenditures, manufacturing procedures, raw materials, and operating expenses. Constructed specifically to meet the demand for producing 12,500 tons of Fluoropolymers (PTFE) per year, the model forecasts profitability while taking market trends, inflation, and changes in raw material prices into consideration. This thorough financial model demonstrates our dedication to providing accurate, client-centered solutions that guarantee the long-term success of major industrial projects by providing the client with valuable data for strategic decision-making.

Latest News and Developments:

- In December 2024, The PCC Group (PCC) announced to construct and run a chlor-alkali facility on the property of Chemours' titanium dioxide (TiO2) plant in DeLisle, Mississippi (USA), according to the Chemours Company (Chemours) (NYSE: CC). Additionally, PCC and Chemours have signed a chlorine supply agreement, subject to certain customary conditions precedent. Once the plant is up and running, the new facility will have up to an annual nameplate capacity of 340,000 metric tonnes and will use cutting-edge technologies to optimise energy efficiency.

- In July 2024, Alfa Chemistry has expanded a variety of fluoropolymer coatings and high-performance fluoropolymer materials like PTFE, PCTFE, and ETFE to their product portfolio. For sectors like chemical processing, electronics, automotive, and aerospace, these cutting-edge materials provide outstanding performance, durability, and chemical resistance.

- In June 2024, Guarniflon® Spa agrees to buy a stake in Shanghai Martina Polymer Materials Co., Ltd. in order to increase its market share in China. With a single core value proposition—closeness to the customer—Martina Polymers has been engaged in China, distributing industrial components made in Europe that are combined into completed systems made in China. With a focus on fluoropolymer and PTFE products, Guarniflon® SpA may now target new market niches in China.

- In May 2023, AGC, glass, chemical, and high-tech material maker has announced that it has chosen to expand its fluorochemical product manufacturing capacity to meet the increasing demand, including for applications related to semiconductors. Operations are expected to start in the second quarter of 2025 at AGC's Chiba Plant (Ichihara City, Chiba Prefecture, Japan) as part of the expansion, which will cost about 35 Billion yen.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Brief List of Our Services: Market Entry and Expansion

- Market Entry and Opportunity Assessment

- Competitive Intelligence and Benchmarking

- Procurement Research

- Pricing and Cost Research

- Sourcing

- Distribution Partner Identification

- Contract Manufacturer Identification

- Regulatory Approvals, and Licensing

- Factory Setup

- Factory Auditing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104