PET Bottle Manufacturing Cost Analysis: Lightweight, High Returns

What is PET Bottle?

A PET bottle is a type of rigid packaging packaging that is produced using a thermoplastic called polyethylene terephthalate, also known as polyester. The production of a PET bottle involves an injection stretch-blow molding technique that provides a lightweight and durable package with high clarity, strength, and impermeability. The primary reason for the popularity of a PET bottle is its ability to store liquids with increased safety and maintain their quality, taste, and shelf-life. Additionally, a PET bottle is recyclable, impact resistant, and meets the regulation standards for contact with food.

Key Applications Across Industries:

PET bottles find wide applications in various sectors owing to their flexibility, robustness, and economical viability. The major use of PET bottles is witnessed in the beverage sector, where bottled water, carbonated soft drinks, juice, sports drinks, and ready-to-drink teas are packaged in PET bottles. This is because PET bottles are lighter in weight, thus reducing transport charges, and more transparent, making products more marketable. Secondary packaging in the beverage sector, specifically carbonated soft drinks, is also carried out in PET bottles, which can withhold high-pressure content.

In food sector applications, PET packaging can be found in edible oils, sauces, condiments, dairy-based drinks, and liquid sweeteners. Food preservation through smooth chemical strength and barrier functions makes PET bottles popular. In personal care and cosmetics, applications of PET bottles are in shampoos, lotions, body washes, hand sanitizers, and liquid soap because of design flexibility. In addition, in home and industry chemicals, cleaning agents, disinfectants, along with car fluids, have applications of PET bottles.

The applications in the pharmaceutical sector include PET bottles used as containers for syrups, oral suspensions, vitamins, and nutraceuticals, where safety, hygiene, and tamper-evident properties are critical. In addition, PET bottles are used as containers for agrochemicals and lab-packaging products. The wide flexibility to shape, size, and close PET bottles allows producers to cater to brand, functional, and regulatory needs as required by the market segments.

What the Expert Says: Market Overview & Growth Drivers

The global PET bottle market reached a value of USD 45.50 Billion in 2024. According to IMARC Group, the market is projected to reach USD 60.30 Billion by 2033, at a projected CAGR of 3.2% during 2025-2033. The PET bottle industry is propelled by the growing demand from the beverage, food, and consumer goods sectors, as well as sustainable initiatives. The biggest driving factor is the steady increase in the packaged beverages sector, especially bottled beverages like bottled water and ready-to-drink beverages, driven by urbanization and a focus on health and hygiene. PET bottles have the advantage of portability, safety, and long shelf life.

Cost effectiveness and superior performance are other factors that propel the PET bottles market. PET bottles are very light, making their transportation environmentally friendly and less costly compared to glass and metallic containers. The fact that PET bottles are shatter-resistant is also a strength. Research and development towards making PET bottles lighter and materials better is increasing.

The issue of sustainability is increasingly influencing the market. Among the most recycled forms of plastic in the world is PET. Consequently, the focus on circular economy approaches has resulted in the rising application of rPET in the production of bottles. The application of recycled materials in the bottles is being promoted by companies as well as the government.

Growth in the personal care, pharmaceutical, and home cleaning categories also adds to demand, since these categories demand durable, hygienic, and aesthetically appealing packaging. The growing online market also supports the use of PET bottles, since light and resistant packaging is required for direct delivery to consumers.

Technological innovations in molding, barrier improvement, and design personalization make way for the creation of differentiated PET bottles. Interconnected factors like consumption patterns, cost advantages, sustainable development, and growth in various industries contribute towards steady growth in PET bottles globally.

Case Study on Cost Model of PET Bottle Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale PET bottle manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed PET bottle manufacturing plant in India. This plant is designed to manufacture 20 million units of PET bottle annually.

Manufacturing Process: The manufacturing process of PET bottles entails a two-step conversion process where polyethylene terephthalate resin is converted into lightweight and robust containers ideal for the packaging of liquids. The manufacturing process begins with the processing of PET resin. The resin is dried in controlled temperature and humidity to remove excess moisture that may adversely affect the quality of the resin if it is processed with the moisture contents present in the resin. The dried resin is next processed in an injection molding machine where it is melted and molded inside precision molds in the form of preforms. The preform takes the shape of a test tube and has the neck and finish of the final bottled product. In the second stage, the pre-forms are heated evenly in infrared ovens to an appropriate temperature for stretching. The heated pre-forms are then loaded into blow molding machines, where they are stretched in the axial direction through the use of a stretch rod and blown radially using high pressure air. The injection stretch and blow molding of the polymer orients the polymer molecules, thus creating bottles that are strong, transparent, and provide good barrier properties. The bottles will have taken the shape of the mold cavity to form the volume, thickness, and features of the bottles. The molded bottles are then cooled, removed from the molds, and transported for inspection. The inspection procedure by quality control checks for size, thickness of walls, weight, and clarity. Bottles are also tested for leaks and subjected to a press test, especially if they are meant for carbonated drinks. The approved containers are either packed or transferred for packing or moved to the filling stations. All manufacturing processes highlight automation, energy conservation, and material resources.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

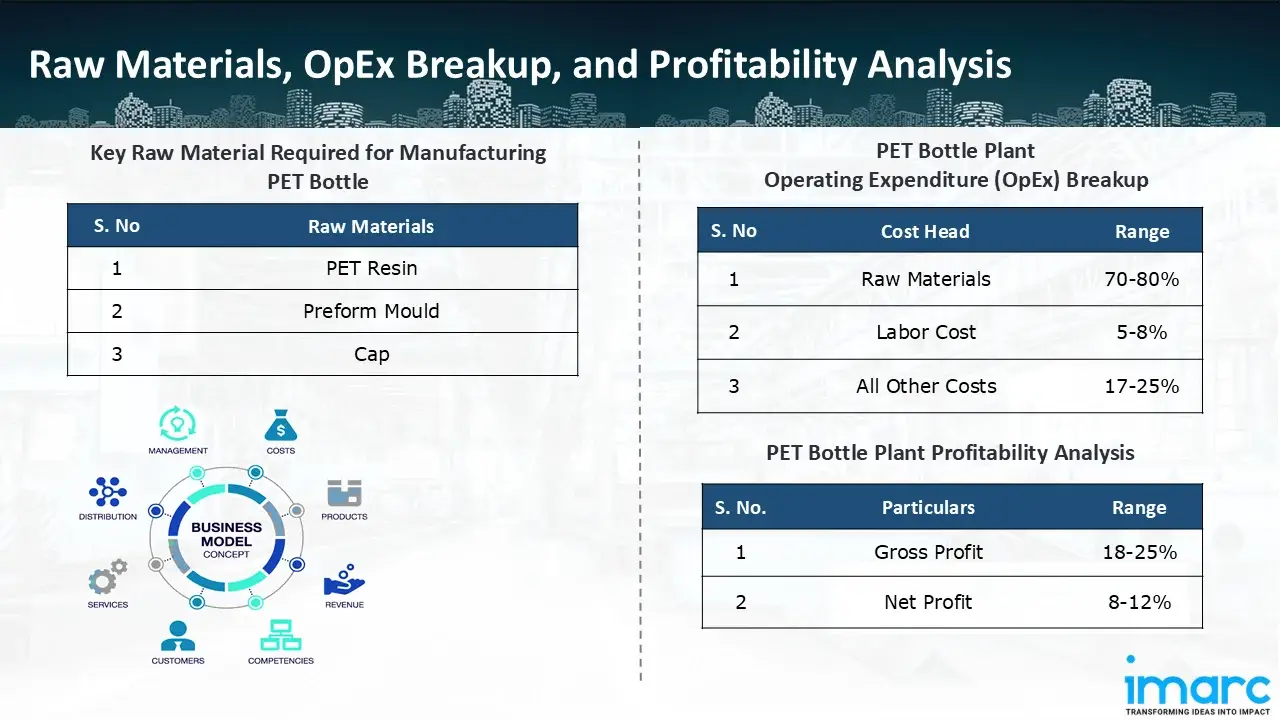

The basic raw materials required for PET bottle manufacturing include:

- PET Resin

- Preform Mould

- Cap

Machine Section or Lines Required:

- Injection Molder (Preforms)

- Blowing Machine

- Filling

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in PET bottle manufacturing plant ranges between 70-80%, labor cost ranges between 5% to 8%, and all other costs ranges between 17-25% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 18-25%, and net profit lie between the range of 8-12% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the PET bottle manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 20 million units of PET bottle annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In October 2025, leading polyurethane system manufacturer Pearl Group has announced a ground-breaking project to repurpose PET bottles for use in its systems. By incorporating shredded PET bottles into its polyester manufacture, Pearl uses this creative method to reuse plastic waste and produce cutting-edge insulation materials with enhanced environmental performance. When completely deployed, Pearl hopes to repurpose 420 million bottles each year.

- In January 2025, PTI (Plastic Technologies Inc.), a pioneer in sustainable plastic packaging design and development, and DePoly, a Swiss award-winning CleanTech business that specialises in advanced recycling of PET/polyester plastics, announced their partnership to produce a closed loop recycled PET bottle.

- In November 2024, ALPLA is joining the PET recycling industry in South Africa. The packaging and recycling expert will operate a cutting-edge facility in Ballito around 1.5 years after development began. The new plant in the KwaZulu-Natal area has received a 60 million euro investment from the corporation. The ALPLA recycling business is expected to start producing up to 35,000 tonnes of recycled PET (rPET) annually in 2025.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104