Breakdown of Production Costs of Ethylene-Vinyl Alcohol (EVOH) Manufacturing Plant: A Cost Model Approach

What is Ethylene-Vinyl Alcohol (EVOH)?

Ethylene-vinyl alcohol, commonly referred to as EVOH, is an extraordinary polymer with outstanding properties that have revolutionized applications in packaging, industrial, and medical fields.

Key Applications Across Industries:

The copolymer consists of alternating ethylene and vinyl alcohol monomer units, which result in the unique gas barrier property that makes EVOH a strong contender for food packaging applications. Its transparency and elasticity, along with its resistivity to both moisture and chemical agents, made EVOH a strong component in the multilayer film packaging process concerning the formation of oxygen and aroma barriers.

What the Expert Says: Market Overview & Growth Drivers

According to an IMARC study, the global Ethylene-Vinyl Alcohol (EVOH) market volume stood at 187.0 Thousand Tons in 2024, growing at a CAGR of 0.9% from 2019 to 2024. Looking ahead, the market is expected to grow at a CAGR of approximately 2.5% from 2025 to 2033, reaching a projected volume of 252.6 Thousand Tons by 2033. This polymer has found a strong foothold in the portfolios of companies across industries because of its diverse properties.

Market drivers and trends for EVOH are practically defined by the excellent barrier properties that position it for widespread applications in food packaging, the automotive industry, and the automotive fuel tank, among others. The primary market driving force behind ethylene-vinyl alcohol demand is the rising need for sustainable packaging solutions. EVOH's superior oxygen and moisture barrier qualities ensure the shelf life of perishing products and minimize food waste. As environmental considerations worldwide increase, manufacturers who want to achieve sustainability for their products are turning toward this polymer. In addition, the automotive industry has recently taken an interest in utilizing this polymer for fuel tank applications, among other things. The medical/pharmaceutical sectors are also using it as a great chemical-resistant material with low extractables.

Case Study on Cost Model of Ethylene-Vinyl Alcohol (EVOH) Manufacturing Plant:

Objective

One of our clients has approached us to conduct a feasibility study for establishing a mid to large-scale Ethylene-Vinyl Alcohol (EVOH) manufacturing plant in Korea.

IMARC Approach: Comprehensive Financial Feasibility

We have developed a detailed financial model for the plant's setup and operations. The proposed facility is designed with an annual production capacity of 30,000 tons of Ethylene-Vinyl Alcohol (EVOH) per year.

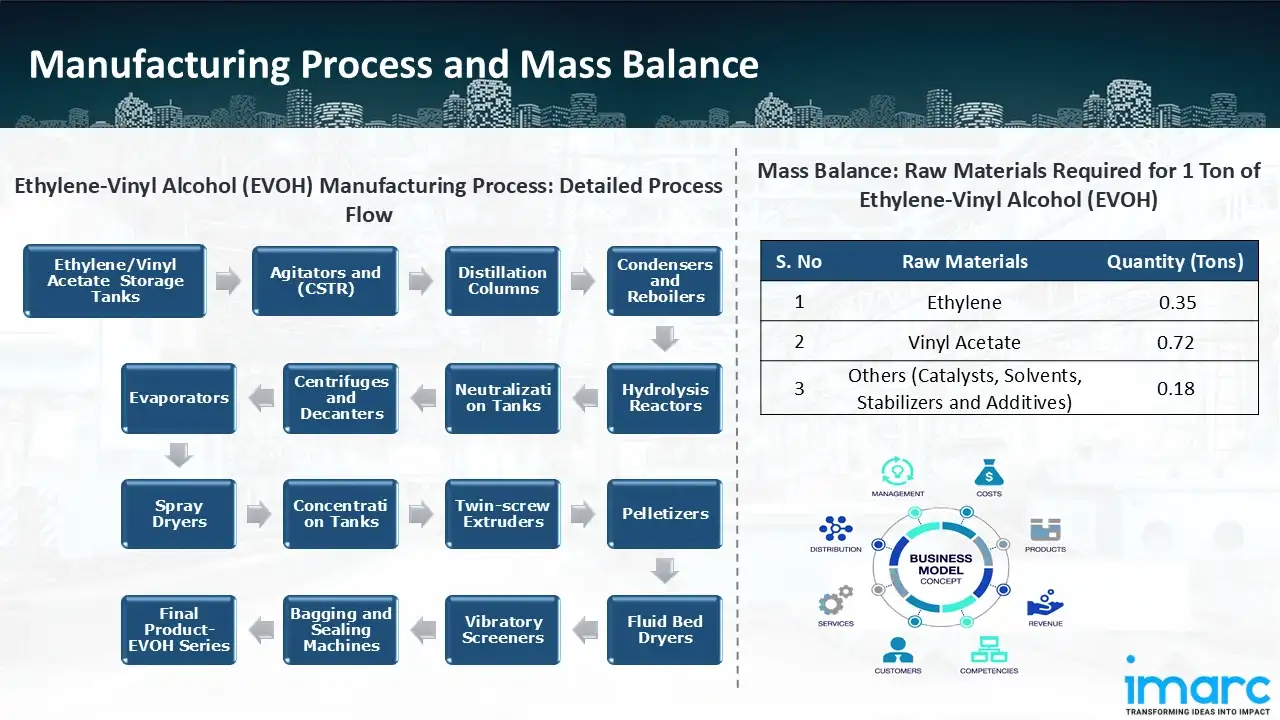

Manufacturing Process: Ethylene and vinyl acetate are first stocked in special tanks to initiate the production of ethylene-vinyl alcohol, EVOH. After adding these raw materials to Continuous Stirred Tank Reactors, CSTR, they polymerize into ethylene-vinyl acetate, EVA. In order to eliminate unreacted monomers from the resulting blend, it moves through reboilers, condensers, and distillation columns. In hydrolysis reactors, the units of vinyl acetate go through a reaction of hydrolysis to give vinyl alcohol. After this process, the polymer is stabilized by neutralization in special tanks. After that, the product is transferred to decanters and centrifuges for purification and separation. Before the polymer solution is dried in spray dryers or fluid bed dryers, evaporators remove surplus solvents to concentrate it. Twin-screw extruders are used to further treat the dry polymer in order to improve its characteristics and homogeneity. To ensure consistent size, the extruded product is screened through vibrating screeners and pelletized. Once that is done, the finished EVOH product is packaged through bagging and sealing machinery to prepare it for distribution. This highly controlled manufacturing process makes high-barrier EVOH resins particularly suitable for industrial applications, car fuel tanks, and food packaging.

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials utilized in the Ethylene-Vinyl Alcohol (EVOH) manufacturing plant include ethylene, vinyl acetate, and others (catalysts, solvents, stabilizers and additives). To produce 1 ton of Ethylene-Vinyl Alcohol (EVOH), around 0.35 ton of ethylene, 0.72 ton of vinyl acetate, and 0.18 ton of catalysts, solvents, stabilizers ad additives.

List of Machinery:

The following equipment was required for the proposed plant:

- Continuous Stirred-Tank Reactors (CSTR) for Polymerization

- Agitators and Mixers

- Ethylene Storage Tanks

- Vinyl Acetate Storage Tanks

- Distillation Columns

- Condensers and Reboilers

- Centrifugal Pumps and Positive Displacement Compressors

- Hydrolysis Reactors

- Neutralization Tanks

- Centrifuges and Decanters

- Evaporators, and Spray Dryers

- Concentration Tanks

- Twin-screw Extruders

- Strand Pelletizers

- Fluid Bed Dryers

- Vibratory Screens

- Automatic Bagging and Sealing Machines

- Digital and High Precision Weighing Scales

- Analytical Instruments and Mechanical Testing Machines

- Waste Treatment Systems (Scrubbers and Filters)

- Boilers

- Chillers

- Air Compressors

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

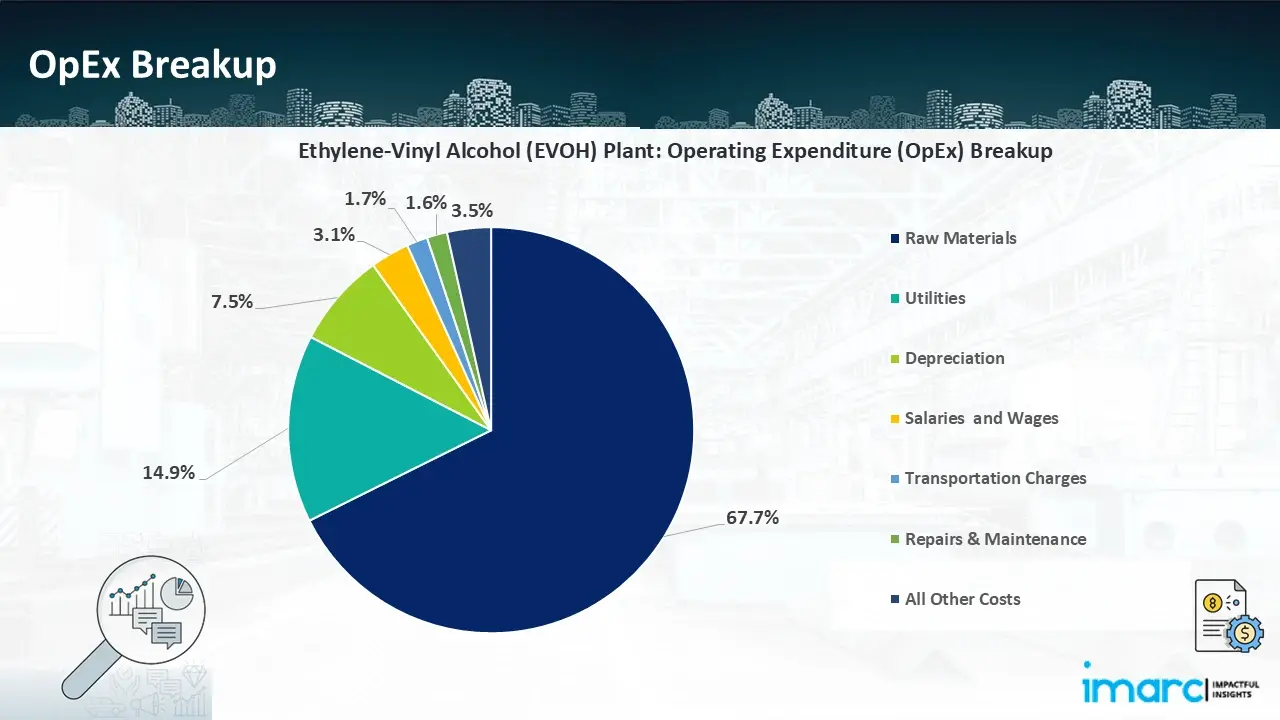

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

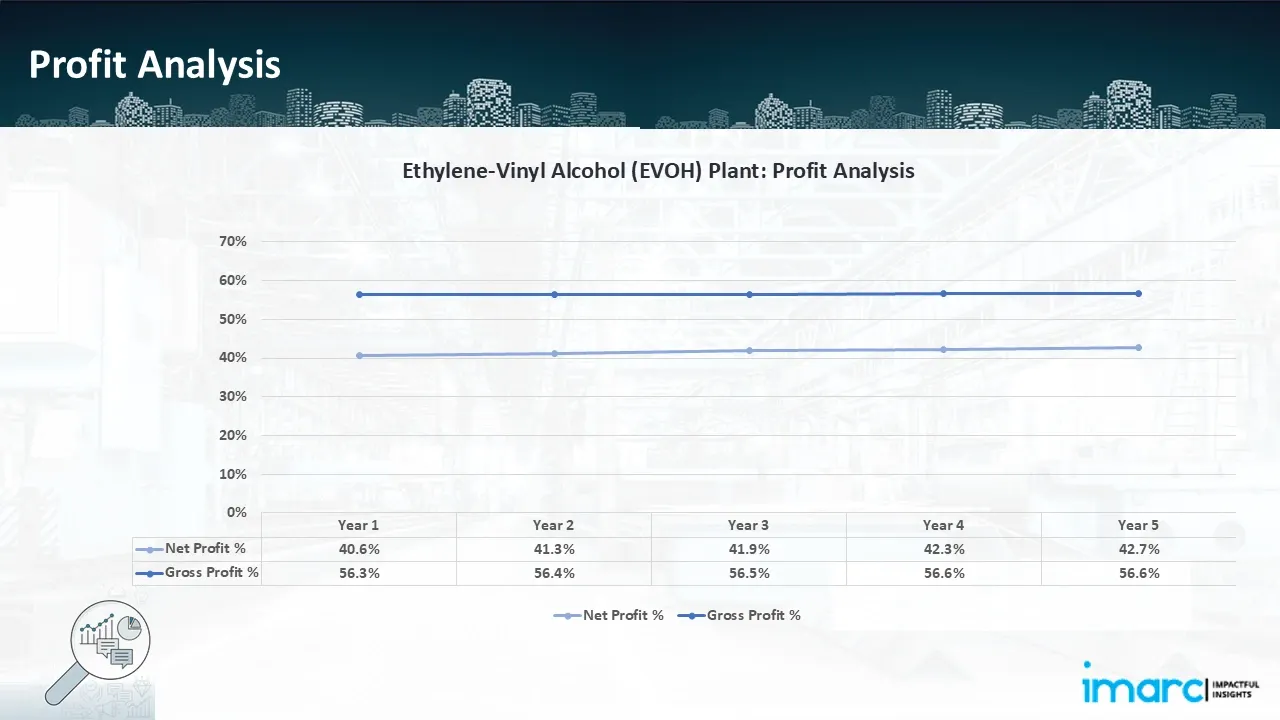

- Profitability Analysis Year on Year Basis: The proposed Ethylene-Vinyl Alcohol (EVOH) plant, with a capacity of 30,000 tons Ethylene-Vinyl Alcohol (EVOH) per year, achieved an impressive revenue of US$ 130.5 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit improved from 56.3% to 56.6%, and net profit rise from 40.6% to 42.7%, highlighting strong financial viability and operational efficiency.

Conclusion & IMARC's Impact:

Our Ethylene-Vinyl Alcohol (EVOH) manufacturing plant's financial model was meticulously modelled to satisfy the client's requirements. It provided a thorough analysis of production costs including capital expenditures, manufacturing processes, raw materials, and operating costs. The model predicts profitability while accounting for market trends, inflation, and any shifts in the price of raw materials. It was created especially to satisfy the demand of producing 30,000 tons of Ethylene-Vinyl Alcohol (EVOH) annually. Our commitment to offering precise, client-centered solutions that ensure the long-term success of significant industrial projects by giving the client useful data for strategic decision-making is demonstrated by this comprehensive financial model.

Latest News and Developments:

- In August 2024, Kuraray Co., Ltd. hosted a groundbreaking ceremony at the proposed location of an EVALTM EVOH resin production plant at Kuraray Asia Pacific Pte. Ltd., a Singaporean company that is 100% owned by Kuraray Co. Ltd.

- In August 2023, Kuraray has announced plans to expand the capacity of its production facilities in the US and Europe for the highly sought-after ethylene vinyl alcohol copolymer (EVOH) resin. The capacity of the American and European bases of operations will be increased by 5,000 tons annually in 2024, and an additional 5,000 tons annually in 2026.

- In March 2023, SK Geo Centric (SKGC) and Zhejiang Satellite Petrochemical inked a contract for the construction of an EAA production facility in Lianyungang, Jiangsu, China, with an anticipated completion date of 2028. After establishing facilities in Spain and the US, SKGC hopes to expand preemptively in Asia to increase its foothold in the global market for high-value minerals.

- In August 2022, the Mitsubishi Chemical Group (MCG) has made the decision to expand its SoarnoL ethylene vinyl alcohol copolymer (EVOH) resin manufacturing capacity in the United Kingdom by 21,000 metric tons annually (m.t./yr) at MCG's Saltend facility. The production increase, which would raise the overall EVOH production output to 39,000 m.t./yr. after construction starts in April 2023, is scheduled to go into effect in July 2025.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Brief List of Our Services: Market Entry and Expansion

- Market Entry and Opportunity Assessment

- Competitive Intelligence and Benchmarking

- Procurement Research

- Pricing and Cost Research

- Sourcing

- Distribution Partner Identification

- Contract Manufacturer Identification

- Regulatory Approvals, and Licensing

- Factory Setup

- Factory Auditing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Under our factory setup services, we help our clients to explore the feasibility of their plants by providing them with complete financial modeling. In addition, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an estimation of capital expenditure (CapEx) for establishing the manufacturing facility, which consists of costs in acquiring land, building construction of the infrastructure, and purchasing high-tech production equipment, along with the installation. In addition to this, layout and factory design have a tremendous impact on the efficiency of the operation, consumption of energy, and labor productivity, thus having an impact on long-term operational expenditure, or operational expenditure (OpEx). Therefore, all parameters are taken care of in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104