MDF Board Manufacturing Cost Analysis: The Fibre Flow

What is MDF Board?

MDF is an engineered wood product produced by breaking down hardwood or softwood residuals into wood fibers, which are then combined with resin binders under heat and pressure. MDF exhibits a homogeneous density, a smooth surface, and fine texture, ensuring a much more workable material compared to natural wood. It is easily machine-processed, painted, and laminated without showing significant warping or grain abnormalities. Owing to its consistency and dimensional stability, MDF has become widely accepted as a substitute for solid wood in furniture, cabinetry, interior paneling, and decorative applications, where precision and smooth finishing are required.

Key Applications Across Industries:

The versatility and reasonable price of MDF boards have made them very popular across furniture manufacturing, interior design, construction, and decorative industries. In the furniture sector, MDF is used to produce wardrobes, kitchen cabinets, bed frames, bookshelves, office furniture, and modular storage systems. Its smooth surface allows easy application of laminates, veneers, paints, or decorative foils, enabling manufacturers to create aesthetically appealing products at competitive prices. MDF’s consistency also supports intricate CNC routing, making it ideal for carved furniture panels, jali patterns, and ornamental elements.

MDF interior and construction usages include wall paneling, false ceilings, door skins, window boards, and partition systems. The variants resistant to moisture, MR MDF, and HDF find applications in kitchens, bathrooms, and places prone to high humidity. MDF also finds essential uses in flooring substrates, backing panels, speaker boxes, and retail fixtures because of its acoustic and dimensional properties.

MDF finds its use in moldings, skirting boards, photo frames, and signage in the decorative products industry because it can be molded or cut with high accuracy and finished uniformly. Moreover, MDF is widely used for exhibition booths, stage setups, and craft products due to its good cutting, sanding, and bonding capabilities. With increasing interest in modular construction and ready-to-assemble furniture across the world, its light yet fairly strong structure makes MDF a favored engineered wood product worldwide.

What the Expert Says: Market Overview & Growth Drivers

The global MDF market reached a value of USD 27.30 Billion in 2024. According to IMARC Group, the market is projected to reach USD 45.80 Billion by 2033, at a projected CAGR of 5.61% during 2025-2033. The market is expanding due to the growing demand for cost-effective, good-quality materials that are used in furniture and construction. The global shift towards modular and ready-to-assemble furniture, influenced by urbanization, shrinking living space, and expanded rental housing, is among the strongest drivers. MDF strikes a balance for cost, machinability, and design flexibility; hence, it is widely appealing for mass-produced furniture.

Another significant driver is the rapid growth of real estate and renovation activities in interior spaces, especially in emerging economies, since increasing disposable incomes spur demand for more modern interiors. Since MDF offers support for premium finishes at lower costs compared to solid wood, it is popularly used for cabinetry, decorative wall panels, and customized home furnishings.

The main contributors to the growing interest in MDF also include environmental trends. Made from wood residuals and fibers that would otherwise be considered waste, MDF fosters resource efficiency and sustainable manufacturing. Growing consumer awareness and a regulatory push toward eco-friendly materials further strengthen MDF's position within the engineered wood market. Advances in manufacturing technology include continuous press systems and low-formaldehyde resin formulations that improve product quality and safety. The product is gaining more acceptance globally, especially within health-conscious markets, as manufacturers migrate to E0/E1 emission-grade MDF.

Besides that, demand is also growing for specialty MDF variants like moisture-resistant, fire-retardant, and high-density boards, widening applications across commercial interiors, hospitality, retail spaces, and industrial uses. Global expansion of large furniture brands and e-commerce platforms stimulates consumption by allowing faster distribution and greater accessibility.

Case Study on Cost Model of MDF Board Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale MDF board manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed MDF board manufacturing plant in India. This plant is designed to manufacture 60,000 cubic meter of MDF board annually.

Manufacturing Process: The process of manufacturing MDF board starts with the procurement of wood residues, such as chips, shavings, and sawdust, at sawmills or from plantation timbers. First of all, cleaning of raw material is undertaken to eliminate impurities or contaminants like sand, bark, and stones. The cleaned wood chips are then steamed and passed through a defibrator, whereby these are mechanically broken down into fine fibers of wood. These fibers are dried up to the desired moisture content before being blended with synthetic resins-such as urea-formaldehyde or its low-emission versions-and wax, which enhance bonding, water resistance, and dimensional stability. The resin-coated fibers are then formed into a fiber mat on a forming line, where the material is uniformly distributed by means of mechanical rakes or vacuum systems. This mat is prepressed to eliminate air pockets and increase the uniformity in density. The mat then enters a hot press where, under high temperature and pressure, the resin cures and compresses the fibers into a dense continuous board. Pressing parameters such as pressure, time, and temperature are carefully controlled so that the board thickness and density reach the desired values. After pressing, the boards undergo cooling, trimming, sanding, and grading. Sanding provides a smooth, consistent quality surface in preparation for the application of veneers, laminates, or paint. The boards are then cut to standard or custom sizes and tested for density, internal bond strength, formaldehyde emission, thickness swell, and moisture content. The finished MDF boards are finally packaged and stored for shipment to furniture manufacturers, construction companies, and retail distributors. This highly controlled process assures consistent quality and performance for the various grades of MDF.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

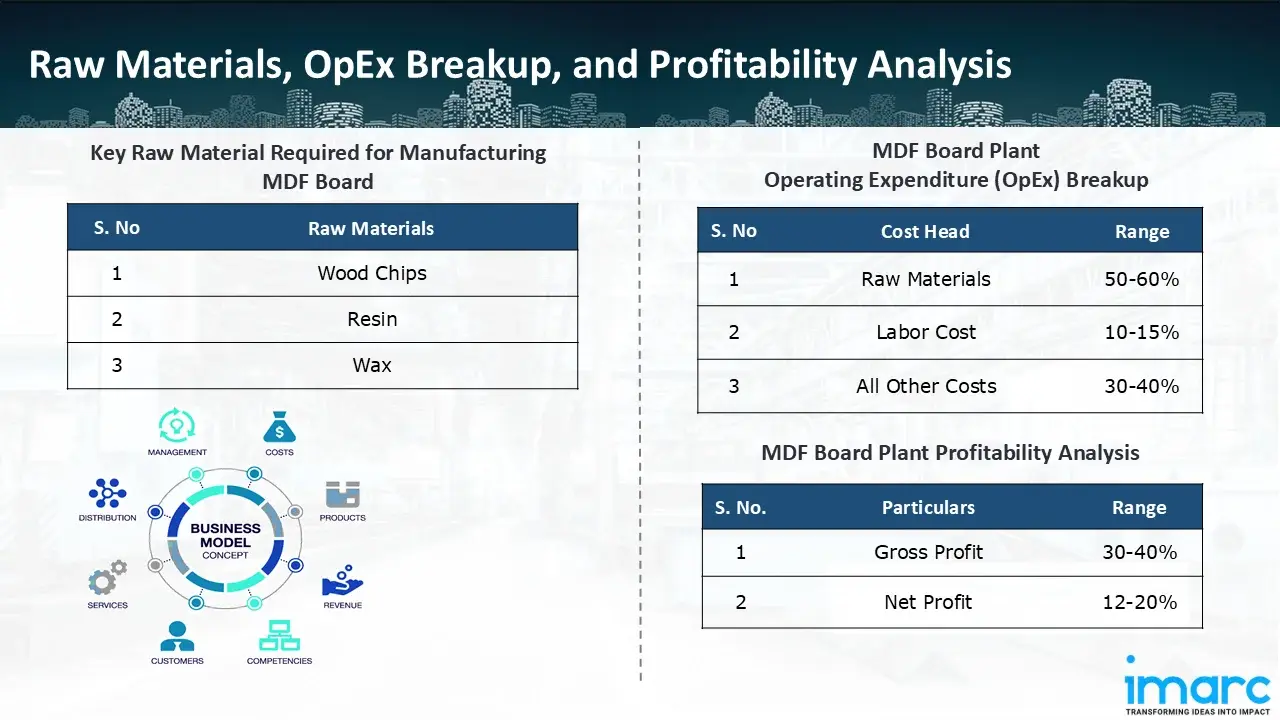

The basic raw materials required for MDF board manufacturing include:

- Wood Chips

- Resin

- Wax

Machine Section or Lines Required:

- Chipping

- Drying

- Blending

- Pressing

- Sanding

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in MDF board manufacturing plant ranges between 50-60%, labor cost ranges between 10% to 15%, and all other costs ranges between 30-40% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 30-40%, and net profit lie between the range of 12-20% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the MDF board manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 60,000 cubic meter of MDF boards annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In April 2025, one of the biggest producers of MDF boards in Brazil, Guararapes, has introduced 11 new items that showcase the latest trends in MDF design.

- In February 2025, Greenpanel Industries announced the commissioning of a new medium density fibreboard (MDF) plant at its current location in the Tirupati district of Andhra Pradesh, with an installed capacity of 2,31,000 cubic meters (CBM) annually.

- In October 2024, CenturyPly announced plans to invest approximately Rs 2,000 crore by 2025 to increase manufacturing capacity in the plywood, laminates, medium density fibreboard (MDF), and particle boards segments.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104