PVC Blister Packaging Manufacturing Cost Analysis: Precision Packaging, Predictable Costs

What is PVC Blister Packaging?

PVC blisters packaging is a type of thermoforming packaging wherein polyvinyl chloride (PVC) material is heated to mold it into packaging cavities to securely place individual items inside, which is then closed with either aluminum foil or paper-based lidding materials. PVC packaging exhibits clarity, strength, and moldability, making it possible to view the individual items while also protecting them against external damage. This type of packaging system provides controlled unit dosage, tamper-evident, and mechanical protection to the items placed inside the blisters. PVC blisters packaging has been largely adopted because of its predictable molding cycles and the ability to support high-speed packaging machines.

Key Applications Across Industries:

The PVC blister package finds universal acceptance in pharmaceutical, healthcare, consumer goods, and other industries for its reliability and economic viability. The dominant segment where it is used is the pharmaceutical industry. In this sector, it is used for packing solid oral forms such as tablets, capsules, and lozenges. The blister pack does support unit-dose dispensing. This advances compliance and precision regarding drug intake. The clear section of the PVC blister package permits inspection of its content. The lidded section is sealable to ensure tamper evidence.

In healthcare products, PVC blisters are employed in medical devices like syringes, test strips, diagnostic kits, and small medical components. The rigid pack safeguards sensitive products from damage and contaminants. As product packaging in consumer goods, PVC blisters are employed in batteries, electronics accessories, health and beauty care products, stationery items, toys, and hardware components. The feature of showcasing items on retail shelves improves merchandising and prevents shoplifting.

PVC blister packaging is also practiced within the food and nutraceutical sector for products like chewing gum, mints, dietary supplements, and functional candies. The industrial sector involves the packaging of small tools, fasteners, and spares. PVC blister packaging, in general, provides optimal visibility, protection, and convenience, which makes this packaging suitable for various end-user industries.

What the Expert Says: Market Overview & Growth Drivers

The global blister packaging market reached a value of USD 26.8 Billion in 2024. According to IMARC Group, the market is projected to reach USD 41.2 Billion by 2033, at a projected CAGR of 4.9% during 2025-2033. The global PVC blister packaging market is propelled by continuous demand from the pharmaceutical and healthcare sectors, growing production of consumer goods, and the necessity for safe, efficient packaging solutions. The expansion of pharmaceutical manufacturing is a key factor, as blister packaging continues to be the favored choice for solid oral dosage forms because of its adherence to regulatory standards, advantages for patient safety, and suitability for automated packaging systems. Growing populations and a rise in chronic illnesses bolster the sustained need for unit-dose medication packaging.

Market growth is also propelled by cost efficiency and the scalability of manufacturing. PVC provides advantageous thermoforming properties, reliable quality, and reduced processing expenses relative to various other materials. These benefits render PVC blister packaging appealing for large-scale production, especially in cost-sensitive and developing markets where affordability and dependability are essential.

Growth in retail and consumer products plays a crucial role in driving demand. With the expansion of organized retail and e-commerce, manufacturers need packaging that safeguards products, boosts shelf attractiveness, and decreases theft. PVC blisters fulfill these requirements by providing robust physical defense and clear visibility of the product. Their suitability for automated sealing and cartoning systems facilitates high-throughput processes.

Efficiency in the supply chain and logistics factors also encourage adoption. PVC blister packs are lightweight, efficient in space, and robust, minimizing damage during transport and cutting down on waste. Furthermore, continuous advancements in material formulations, reduced thickness, and compatibility with recycling assist manufacturers in tackling environmental issues without compromising performance.

Although there is growing interest in alternative materials, PVC blister packaging remains widely used because of its established infrastructure, reliable performance, and regulatory approval. Pharmaceutical growth, cost benefits, retail growth, and manufacturing effectiveness together promote ongoing global demand for PVC blister packaging.

Case Study on Cost Model of PVC Blister Packaging Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale PVC blister packaging manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed PVC blister packaging manufacturing plant in India. This plant is designed to manufacture 100 million of blisters annually.

Manufacturing Process: PVC blister packaging manufacturing requires a set of material preparation, thermoforming, product insertion, sealing, and finishing operations combined to produce secure packaging solutions. The process for PVC blister packaging begins with the selection of PVC film, either pharmaceutical-grade or consumer-grade, in roll form. The PVC film unwound from the rolls will be processed through a thermoforming machine, where the PVC film will be subjected to a predetermined temperature, causing it to become flexible. After being softened, the PVC film will be created into cavities through vacuum, pressure, or a combination of both forces. After blister formation, the blister cavities are chilled to maintain shape before indexing to the filling station. During this process, drugs like tablets, capsules, medical parts, or consumer products are positioned into each blister cavity accurately by automated feed systems. The blister packs containing these drugs then go to the sealing area where a lidding material, usually aluminum foil or paper, is put on top. Applying heat and pressure, a strong seal is created by binding the lidding material to a PVC film. In medication packaging, sealing speed and time must be carefully controlled to manage package integrity along with different requirements. After sealing, the blister web is inspected for defects in terms of missing products, incorrectly sealed blister packs, and damaged cavities in blister packs. Approved blister packs are then punched or die-cut into individual blister packs or strips using punching or die-cutting machines. Other final process steps include printing, batch coding, and packaging of blister packs in cartons or secondary packs. All through this process, process validation, hygiene, and quality assurance are emphasized.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

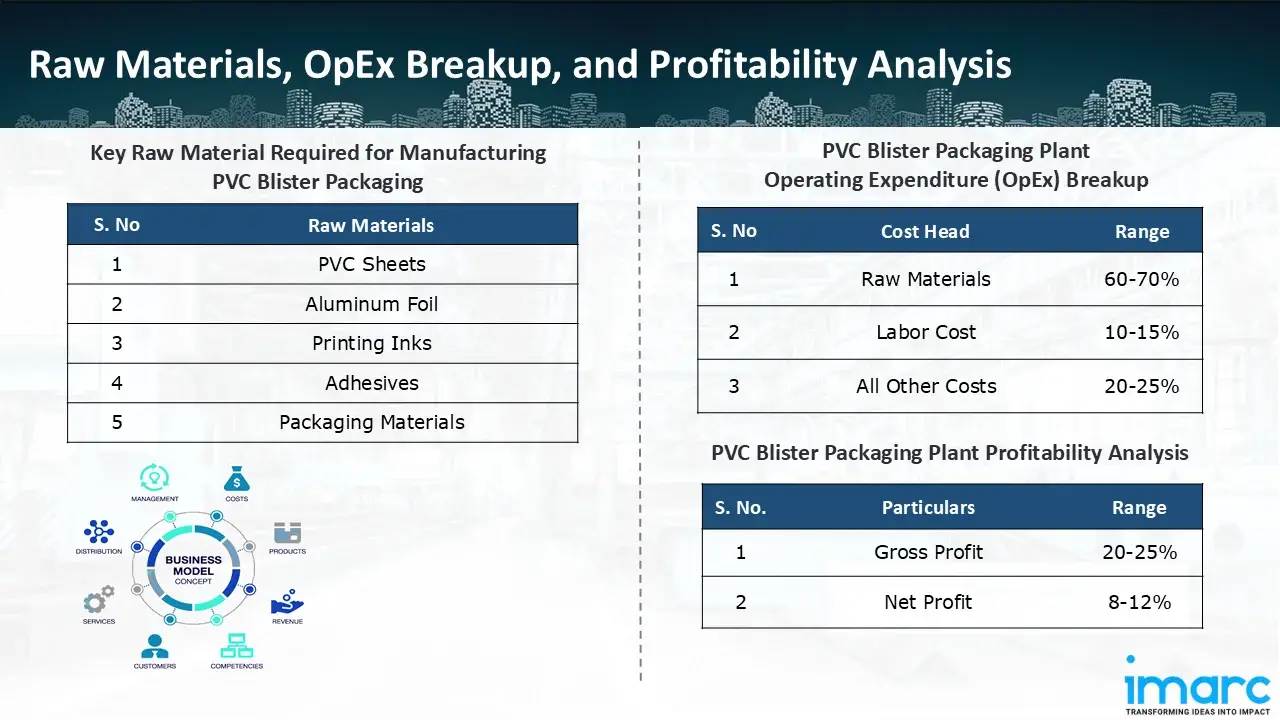

The basic raw materials required for PVC blister packaging manufacturing include:

- PVC Sheets

- Aluminium Foil

- Printing Inks

- Adhesives

- Packaging Materials

Machine Section or Lines Required:

- Sheet Extrusion

- Thermoforming

- Printing

- Sealing

- Cutting

- Packing

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in PVC blister packaging manufacturing plant ranges between 60-70%, labor cost ranges between 10% to 15%, and all other costs ranges between 20-25% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 20-25%, and net profit lie between the range of 8-12% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the PVC blister packaging manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 100 million of blisters annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In May 2025, a mono-polypropylene blister solution for dietary supplement packaging was introduced by SÜDPACK Medica with the goal of meeting the recyclability requirements of the Packaging and Packaging Waste Regulation while preserving product performance and contact safety.

- In April 2025, Amcor, a player in developing and producing responsible packaging solutions, announced it has secured a commercial order of AmSky™ Blister System with the launch of the new TheraBreath Invigorating Icy Mint chewing gum currently available in major retailers across the U.S.

- In December 2024, the CPH Group's Packaging Division declared its intention to purchase LOG Pharma, a business with manufacturing facilities in Hungary and Israel. The CPH Group's expansion strategy continues with the acquisition of this producer of supplemental packaging solutions for the pharmaceutical and medical industries.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104